Zeiss Ikon Contax Camera Repair

A home for your Zeiss Ikon Contax, Contarex or Super Ikonta camera!

- Home

- Information

- Articles

Index

Sections

- What about Doing Your Own Work?

- What are Shutter Tapes and Why Replace Them?

- What is a Complete Shutter Overhaul

- What are Shutter Leathers?

- Why is a Range finder Overhaul Necessary?

- Why is a Lens Service Necessary?

- What is a Critical Camera Alignment?

- What is Original Contax Quality?

- What is Getting a Shutter to Work?

- How is the Initial Shutter Spring Tension Set?

- What are the Proper Lubricants for a Contax Camera?

- Why is an Internal Lens Cleaning Necessary?

- Are Lens Repairs Available?

- What is a Critical Camera Alignment?

CONTAX II/III Camera Information

What About Doing My Own Work?

The temptation to save some bucks and do a home-brew overhaul is great. Unfortunately, the complexity of the Contax cameras is equally great. It is very difficult to put it into words except to say simply that the prognosis for a camera that is disassembled by a person who is doing so for the first time is not good. There are four main reasons for this.

The first reason is that about two out of every three Contax cameras did not work when they were sold. My experience is that a Contax that took good pictures got used well and got a lot of wear marks; and a Contax that didn't work sat on a shelf and kept its good looks. Today people pay a big premium for a Mint Contax only to find there is something important about it that doesn't work right. The reason for this is fairly simple. The Contax camera is hand made out of parts that are largely hand made. The key to the making of a great picture taking Contax was in the hands of the person who originally assembled the camera. Unfortunately, the assemblers in the Zeiss factory had the lowest status and were paid on a piece work basis. It takes a lot of skill and careful fitting of parts to each other to make a camera that works right. You must put the camera together and then take it apart many times during this process. My guess is that a good assembler could put a single good camera together in a comlete working day. But a single camera would't pay the rent at piece work pay, so many cameras were simply assembled as quickly as they could be and these have never taken a decent picture. The result is that finding the little fault that has caused the camera to sit on a shelf for fifty years or so requires vast experience. I can tell you from experience that I have serviced over 150 Contax cameras and I am still finding ones with "from the factory" problems I have never seen before. There are many parts in a Contax, and with each being hand made, each has many possible modes of having been made wrong.

The second reason is not obvious. The inner workings of the Contax are filled with old grease that is in an advanced, but very slowly proceeding state of oxidation, hardening and separation. While the Contax body is not absolutely air tight, the exchange of air from inside to outside the camera body where the mechanical works are located is very slow. When the camera body is opened and exposed to fresh air, the lubrication is exposed to abundant oxygen and the deterioration proceeds rapidly. This is why I have instituted a standard servicing that covers everything. I found that it is almost impossible to fix a single thing on a Contax and then get it put back together before something fails due to grease gone hard or sticky. Proper lubrication of a Contax requires five types of grease and two types of oil.

The third reason is that the Contax goes back together differently from the way it came apart. The reason for this is that most people who are not familiar with the Contax disassemble it too completely and separate parts that have critical alignments. It is also possible to separate parts that are not intended to be separated and which are irreparably broken when separated. In many cases removal of one part through the "jigger" use of a normal tool not made for the purpose will cause the breakage and bending of another part.

The fourth reason is simply that expensive alignment tools are absolutely required to adjust the Contax shutter and body. An autocollimator, shutter speed tester and precision light source are absolutely necessary. It is important to know that adjustment of the Contax shutter requires the very delicate manipulation of components and the proper positioning of some others when the camera is assembled. If you don't know what you are doing extremely well it is absolutely impossible for you to assemble a Contax so that it will work better than it worked before it was taken apart if you are lucky enough to be able to get it together so that it works. Many people will need a shutter speed tester to be able to convince themselves of this. The simple fact is that the shutter speeds must be kept in mind while the first to the last part is being put back into the camera body. There are a lot of tricks.

There is no good reason to decrease the number of working Contaxes out there. If you have a camera that you think needs work, please send it to me. I will send it back to you in the best condition it is possible to be in, you will be happy with it, and it will have increased value.

If it is too late and you have a box of parts on your hands, please consider sending them to me for an assembly estimate. I will be merciful and will not take advantage of you. If it is impossible to put them all together into a complete camera I will give you a fair offer for them.

Here's one thing to keep in mind. The retail price of a Contax IIa black dial with the 50mm f1.5 Sonnar was $318.00 in 1953. This was the same price of a new car then and is roughly equivalent to $3400.00 in toady's dollars. If you have purchased a Contax with a lens for $300.00 or so, you have paid less than 10% of its value. So if you pay $200.00 more to have it made back to like new, you are still way ahead of the person who bought it when it was new. And when a camera leaves my hands it is better mechanically than when it was new because I use new and modern synthetic clock and watch oils and greases that will not deteriorate so your camera will operate like new for many many years. And even if you did buy one and take it apart, you still want a working Contax, and you have to buy a another one to send to me, its not a complete loss.

I will allow a credit for the parts for the disassembled camera. And even if it should cost you $$650.00 for two camera bodies, a lens and a servicing, you are still way ahead of the persons who purchased the two bodies originally. So please, please please, if you want a real Contax in your hands when you put film into it, send it to me to be serviced and don't try it yourself.

What are Shutter Tapes and Why Must They Be Replaced?

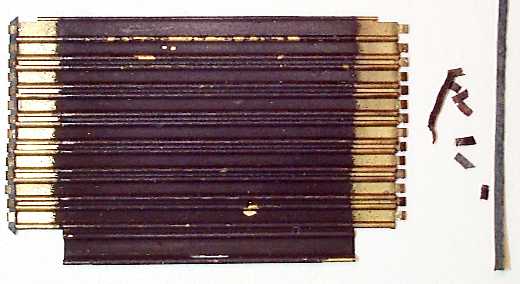

The illustration

is of shutter curtains and shutter tapes. The shutter tapes are thin

silk ribbons of a special weave made out of only one specific silk fiber

type out of over 1500 possible silk fiber types. They are 11.0

centimeters long, 3.0 centimeters wide, and 0.250 centimeters thick.

It is important the tapes be made of silk because unlike modern fibers,

silk will not stretch. This is important because the use of modern

materials which stretch will cause the shutter speed to change as the shutter

tension increases. Zeiss used silk for this reason and also because

it is very long lasting, will not fray, does not absorb water or oil, and

has low friction.

They attach at the bottom edge of the upper shutter curtain and to spring rollers at the right and left of the lower shutter curtain roller. They transmit the spring force to the upper shutter curtain to pull it down when the shutter is released. Like all fabric, the shutter tapes deteriorate over time and eventually tear under the shutter spring tension. They can also fray causing the shutter to slow down or jam.

You know you need new tapes when the winding knob turns, but the shutter curtains do not rise, the shutter curtains are cocked part open, you can see threads or fabric from behind the shutter, or the shutter moves jerkily.

The service provided by other repair shops that is called a "shutter overhaul" consists of replacement of these tapes using substitute materials and external oiling of shutter components. Shutter tape provided by me is made of silk and is identical in all respects to the original Zeiss tape.

Shutter tape is a matter of great interest to most people who are interested in ZEISS IKON Contax cameras. There is much discussion of it on various camera sites on the internet. The last supply of Contax shutter tape was taken by the Russians at the end of World War II. The Zeiss factory in Jena was disassembled and carted off to Russia. Since then, and until now, there has been no supply of original Zeiss specification shutter tape. Since the end of the war, people have used just about anything in the Contax cameras to keep them running. Some people have used decorative silk or rayon ribbon from the craft store; others have used the Russian nylon tape used in the Kiev line of Contax copy cameras. The problem with these substitutes is they do not work well. The Zeiss shutter is incredibly complicated. Its mechanism is very precise and sophisticated.

Each and ever part was designed. Nothing was left to chance by the original Zeiss engineers. The shutter tape was carefully designed just as was every other shutter part. Shutter tape which is not in accordance with the original design will not allow the shutter to properly function at all speeds. The shutter tape plays a very important function in shutter speed control. The use of substitute tapes will provide the appearance of proper shutter function at slow speeds, but the high speeds will not be accurate and will be much slower than indicated. It has taken me thousands of dollars, and over three years of effort, but I finally found a silk manufacturer that would produce a limited amount of silk tape using the same fiber and weave as the original Zeiss tape, and make it to the same dimensions. The manufacturer has informed me they will not produce a second batch of this ribbon. I have only the one order, and it is sufficient to last me for the rest of my active camera repair life. Only this original specification shutter tape is used in each and every ZEISS IKON Contax camera I either overhaul or in which the shutter tape is replaced. No matter what anyone may tell you to the contrary, the only supply of original Zeiss specification silk shutter tape that exists is in my possession. I have obtained samples of all the shutter tape used by people in the camera repair business over the past five years and who repair ZEISS IKON cameras. I have used this tape in cameras that have been completely overhauled by me. None of these tapes have provided satisfactory shutter performance. Only when the original Zeiss specification silk tape is used can a camera be repaired to meet the original factory specifications for the shutter speed. There are some who say that the reason Zeiss used silk is because there was nothing else available to them at that time. This is not true. Rayon, nylon, cotton, wool, and other fibers were available. Zeiss decided to use silk because it was necessary to meet the design requirements of the shutter. There is no substitute.

I have found this out by careful testing using substitute materials. I would not have gone to the effort and expense of obtaining original specification tape if there was a satisfactory substitute material.

Tape replacement can be performed with the shutter in the camera. This is why you should understand that when only the tapes are replaced, the 55 year old lubricants in the camera still remain. If you want like new performance, a full shutter overhaul is necessary. To learn more about this service use this hot link: Shutter Tape Replacement Service. Please read the next section if you want to know why a complete shutter overhaul, as I define it, may be what you want.

What is a Complete Shutter Overhaul and How is it Different From Shutter Tape Replacement?

This is a picture showing most of the parts in a Contax shutter.

All these parts are hand cleaned and/or ultrasonically cleaned and polished

as part of a complete shutter overhaul. Like most things, it depends

on who you talk to. If you call other camera repair shops that work

on old Contax cameras they will tell you a shutter tape replacement is

a shutter overhaul. I am sure they actually believe this to be true.

However, I found out by careful testing that a normal "shutter overhaul" does not restore the original accuracy and repeatability to an old shutter. To restore this accuracy requires a complete shutter disassembly, careful individual cleaning of all components, one micron diamond compound polishing of all shafts, journals and bearings, and reassembly using modern synthetic clock and watch lubricants. This is a tremendous amount of work. The typical price for a "shutter overhaul" as performed by others is usually $175.00 or more and does not include complete disassembly and cleaning of all parts. The work I have described above takes about 20 hours or more depending upon shutter condition. There is no way anyone can do all this for $175.00. So what you get from others for your $175.00 is replacement of the shutter tapes using substitute materials of approximate size, and some external oiling of the shutter to get it to move. Replacement of the shutter tapes can be done with the shutter in the camera. This is why I only charge $125.00 for this job.

You also get original Zeiss specification silk shutter tape which is available no where else. The testing I performed to determine if a normal shutter tape replacement is a true shutter overhaul is simple. I sent two cameras to a person advertising to perform shutter overhauls on Contax cameras. When the cameras returned, I tested the speeds on a shutter speed tester. The results were terrible. Here they are:

1 sec = 1.25 sec, 1/2 sec = 1/3, 1/5 = 1/10, 1/25 = 1/50, 1/50 = 1/90,

1/125 = 1/100, 1/250 = 1/175, 1/500 = 1/200, 1/1250 = 1/250.

Notice they get progressively worse as the speeds go higher. In addition, the repeatability of each speed is no good. The speeds go all over the place and you never get the same speed twice. I took one camera and progressively tightened the shutter tension spring in an attempt to get better than a 1/250 actual speed at the 1/1250 setting. The best I could get was 1/300, but with this the "slow" speeds were way too fast. A complete explanation of this phenomena is beyond the limits of this page. If you want the whole story, use this hot link: Shutter Details to go to my detailed shutter page.

What are Shutter Leathers?

Shutter leathers are very important to the operation of the shutter. Each shutter curtain is made up of very thin and precisely formed brass blades. The fit together with a sliding joint. Leather strips running down each side of the curtain restrains the blades from moving from coming loose, moving and becoming damaged during shutter operation. The leathers keep the blades from moving out from the side and causing the shutter to jam. The original leathers are, like all the other components, over 50 years old, and in many cases are deteriorated, hardened and cracked. It is not possible to obtain the high speeds on a shutter with old leathers. Flexible leathers are needed since the old leathers add friction when the curtain is rolled around its roller. The following is a picture of a shutter curtain with the left leather replaced, and the right leather removed. The old leathers always come out in fragments and these are shown to the right. To the right of the old leather pieces is a new leather ready to be installed:

Replacement of the shutter leathers, if required, is included in a complete shutter overhaul.

Why is a Range finder Overhaul Necessary?

By the time a Contax range finder mechanism has had fifty or more years to age, all of the grease in its gears and bearings has gone hard and is extremely dirty. Dirt has built up in the lens mount focusing helical threads. The variable position cylinder lens that makes the secondary image shift has become loose in its mount due to adhesive deterioration. The optical surfaces have become dim and hazy due to being covered with a thin film of oxidized oil that has migrated from deteriorated shutter grease.

All of these factors make it certain that an old Contax will have a focus wheel that is tight, a hazy dim view, and a range finder that is inaccurate.

A complete range finder overhaul consists of removal and cleaning of all its parts. New modern synthetic clock and watch lubricants and greases, along with a teflon treatment to the lens mount helical threads ensures the range finder "feel" will be feather light but positive, the range finder window will be crystal clear and bright, and the range finder will be completely accurate throughout its range. Occasionally one can come across a camera with clean and clear viewfinder. In most cases, this is a camera that had the optical components cleaned. These can be cleaned without extensive camera disassembly. It makes a camera easier to sell. But the other range finder problems remain. A complete range finder service requires complete camera disassembly, ultrasonic cleaning of all the parts, and relubrication. This is why this service is $75.00.

Why Is A Lens Service Necessary?

The damping grease originally used by Zeiss in its lens aperture mechanism and on the focusing helical threads deteriorates. When it deteriorates it separates into oil and gel. The oil migrates over the inside and outside of the lens. People do not notice the outside film because it is so thin. The oil film is very visible when on the internal lens surfaces because it makes the lens hazy. Removal of the old grease and oil requires complete disassembly of the lens into all of its components followed by a solvent cleaning in a number of solvents to ensure all of the lubricant components are completely removed. When the lens is reassembled modern synthetic non deteriorating and non migrating damping grease is used to restore the lens to its original feel.

The external appearance of the lens is improved as well. While the external oil film is not noticed when present, it's absence makes a noticeable improvement in the chrome. Even when the oil film is not visible to the eye in the lens, it is there and it does degrade the lens optical performance. A lens with a visible film or "hazing" is optically useless. Removal of the oil film restores the internal lens surfaces to their original optical performance.

Critical Camera Alignment

Whenever any event occurs that can affect the alignment of the plane of the lens mount to the plane of the film guides, this alignment must be checked and then adjusted if necessary. Such events are the camera being dropped or abused, or removal of the lens mount for camera repair.

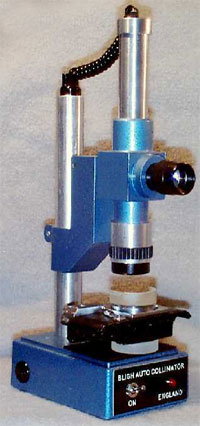

In addition, the original alignment may have been incorrect. The range finder service, complete shutter overhaul, and complete camera overhaul services involve removal of the lens mount. These services include critical camera alignment of the lens mount to ensure it is absolutely parallel to the film plane. This alignment is performed using an extremely precise optical instrument, the Autocollimator:

In the picture you can see a Contax II on the stage of the autocollimator. The camera body is resting on an optical flat, and another optical flat is placed on the lens mount. An optical flat is a disk of optical glass that has been polished to a flatness and parallelism of 1/4 of a wavelength of light. Each flat has a front surface mirror surface.

The autocollimator sends out a precise beam of light with a reticle pattern. This beam is reflected from a reflective surface on the instrument stage, back into the instrument, and onto a calibrated reticle that is viewed in the eyepiece. The deviation from parallel of the reflecting surface on the stage is shown by the misalignment of the projected reticle to the eyepiece reticle. Camera alignment is accomplished by viewing through the camera body to the optical flat front mirror surface against the film guide rails. This checks the body is not distorted. A normal body will have perfect alignment. Next, the flat is placed on the lens mount, as is shown in the picture. Shims of thin brass are placed under the lens mount to adjust it into precise correspondence with the plane of the film guide rails if any adjustment is required. It is not possible to obtain the extreme high quality images the Zeiss Sonnar, Biogon, Planar and other lenses made for the Contax Cameras can produce if the camera and lens mounts are not in precise alignment.

It is not possible to align these without an autcollimator.

Contax Quality

Many people do not realize just how special Contax cameras are. Because they look modern, it is assumed that they are somewhat modern. Nothing could be further from the truth. Each and every Contax camera was hand made and each is full of hand made parts that have been hand fit to each camera mechanism individually. Each camera is an individual requiring an individual approach and understanding. The main purpose of all this effort and work was to make a camera that would take the sharpest picture it is possible for a camera to make. This was goal of the Zeiss company in making these cameras. The Contax cameras of all models are capable of taking pictures of the most astounding sharpness and depth. But sadly, most cannot achieve this goal due to age, deterioration and wear.

The restoration of this full potential requires the special care and delicacy in the handling of the camera and its parts during maintenance that are based upon knowledge, experience and respect. It also requires the use of calibrated precision measuring and evaluation instruments to evaluate the final assembled body and/or lens to ensure the required alignments have been performed so that when the range finder is focused on an object the result is that the full potential of the lens is realized, and the sharpest possible image is projected onto the film plane. This is my goal. This is why each and every camera body and lens maintained by me has a full no question one year guarantee.

Because each and every camera is a hand-made one of a kind photographic instrument, I will discuss your cameras and lenses with you as they are evaluated prior to maintenance. You will be kept fully informed when your camera arrives, the results of the initial evaluation, any significant findings during the maintenance work, the results of the final evaluations, and when your camera is shipped back to you. Your camera or lens is as important to me as it is to you; and I am as interested in your getting satisfaction and performance from them as you are.

Getting A Shutter To Work

There are some people who have written "repair manuals" for the ZEISS IKON Contax cameras. These repair manuals say all you need to do to get a shutter working is to oil it up on the outside of the mechanism, and then work the parts to free them up. I have these manuals. They are full of nonsense. A working shutter is one that operates well at all speeds. When a shutter is worked over superficially as instructed by the published manuals, the result is a shutter that appears to work. I say appears to work because it appears to function at the low speed settings of B, 1/2 and 1/5 second. The confidence instilled by this shutter functioning is based upon the behavior of modern leaf type shutters. Typically, a leaf type shutter that is in need of a cleaning will slow down or hesitate on the low speed settings of B, 1, 1/2, and 1/10. Such a shutter will function well at the high shutter speeds.

This modern shutter behavior convinces people that when a Contax shutter is oiled so that it works at the low speeds, it will also work at the high speeds. This is an incorrect assumption. It is incorrect because the Contax shutter operates on entirely different principles, using an entirely different mechanism than modern shutters. The Contax shutter relies upon the absence of friction to obtain the high shutter speeds. People winding a Contax camera will notice that the spring is wound tighter for the lower speeds, and to the least extent to the highest speed of 1/1250 second. Without going into a complete explanation of the working of the Contax shutter, suffice it to say, that when the camera is set at the 1/1250 second speed, the spring is tensioned to the least possible value. Hence, the highest shutter speeds rely solely upon the shutter mechanism having the least possible internal friction. A shutter that has been externally oiled and then worked to loosen it up is a shutter that is bound up and tight.

With such a camera the highest actual speed obtainable when the camera is set at 1/1250 second is about 1/80 second. The only way to get original factory specification shutter speeds is to completely disassemble it, clean each part, and then to reassemble it, using original Zeiss specification silk shutter tape.

Setting The Initial Shutter Spring Tension

I am inserting this section to satisfy the curiosity of those who have done their own work on a Contax shutter, and are confronted with the question of setting the initial shutter tension. One manual advises setting it until the shutter curtain exerts a force of 300 grams. This is dangerous nonsense. The shutter spring shaft should be wound absolutely no more than five (5) full turns. To turn the shaft more runs the risk of almost irreparable damage to the shutter spring assembly. With the shaft facing you, wind the shaft in a counter-clockwise direction.

Wind it no more than five turns after the tape is fully taken up onto the rollers. Be sure to wind in the proper direction, winding in the wrong direction can damage the central shutter spring. The lower shutter roller contains three springs. The right and left springs are attached to the rollers that wind the shutter tape. The central spring acts on the lower shutter curtain. When the winding shaft is turned, all three springs are tensioned simultaneously. It is possible to over tighten the center spring to the point where it is permanently deformed, and ruined, without damaging the outer right and left springs. Damage to the center spring is not evident at the low shutter speeds. When the shutter operates at B, 1/2, 1/5, and 1/10, the broken center spring will still be capable of pulling down the lower shutter curtain fast enough, and so the shutter will appear to work properly.

At higher speeds, the broken spring will not be able to pull down the lower shutter curtain fast enough, and the result will be partial frame exposures. The extent of the frame exposed will decrease with increasing speed.

Whenever I rebuild a camera I always disassemble the lower shutter roller and inspect the springs. In the event a spring should be damaged, I have spares on hand, or can manufacture a replacement spring.

The Proper Lubricants

Zeiss used marine (whale) based lubricants when the shutters were manufactured. These lubricants, with the exception of antique clock and watch lubricants, are not available today. It is important to understand two things. Firstly, all liquid lubricants have the property of covering all surfaces over time.

This means that over time, the oil in the shutter will migrate over all of its surfaces, and then it will migrate out to cover all of the camera internal and external surfaces. All old Contax cameras are uniformly coated with a layer of oxidized oil. This film is very thin, and almost transparent. This is why the range finder lenses and windows are clouded and the chrome is dull. Secondly, most greases will degrade and separate into oil over a long time. When a camera is made to work by a careless external oiling of the shutter using simple petroleum based oil, such as "Three In One" or the like, all one is doing is oiling the entire camera. This oil will be quickly wicked over and inside the entire camera by the old oil film. The existing oil film will conduct the new oil quickly.

When a camera is rebuilt properly, all of the inner and outer surfaces are carefully cleaned of the old oxidized oil surface. This alone requires hours of work.

Modern clock and watch lubricants are available, but are extremely expensive. However, these are the only lubricants that allow parts in the shutter to function properly. The original lubricants used in the Contax shutter were marine mammal based. These particular lubricants require a certain surface finish on the mating surfaces of the shutter components. Since marine based lubricants are no longer available it is necessary to use extremely fine diamond polishing compound to improve the surface finish of some of the shutter components to make them compatible with modern synthetic lubricants.

Cleaning The Lens

The inner and outer surfaces of all the the lens component lenses get coated with the same layer of oxidized oil that coats the camera. Contrary to popular belief, the lens is full of grease. It was put in when the lens was manufactured to damp the operation of the aperture ring. This damping grease is more prone to deterioration and separation than is the lubrication grease used in the camera body.

A lens showing "oil" on the aperture blades is a lens whose elements are likewise coated with oil. It is not possible for a lens to produce images that are critically sharp unless it has been precision cleaned and aligned. If it is your intention to use the negatives from your Contax camera to make enlargements, you should strongly consider having your lens cleaned. You will notice the difference in the lens and in its performance.

The lens must be cleaned using laboratory analytical grade reagent solvents. These are very expensive, but they are the only solvent that leaves no residue. The focusing helical and the aperture mechanism must also be cleaned of the old oxidized lubricants. There are some extremely fine modern synthetic damping greases available for use in these mechanisms. The new lubricants do not migrate or oxidize. When a lens is cleaned and lubricated by me, it will never need another cleaning ever.

Lens Repairs

Occasionally a lens will require repairs. Over time lenses can develop separation between cemented elements, loss of coatings, mold and fungus, or mechanical problems. All of these conditions can be corrected with the lens being brought back to its original state of performance. Since the cost of services that cannot be performed by me and must be obtained from other vendors are subject to change, it is not possible to specify prices for these services here. If you have a lens with these problems, please write to me so that an accurate estimate can be provided to you.

Camera Alignment

Whenever a camera is disassembled, the lens to film plane alignment may be affected. In all cases, it is necessary to check this alignment, and to adjust it, if necessary. There is only one instrument that can be used for this purpose. This instrument is called an Auto-Collimator.

Each and every camera I repair is checked on an Auto-Collimator to ensure the lens to film plane alignment is perfect before the camera is packaged for shipment. Most, if not all, home camera repairers do not have access to this instrument. It is too expensive.

The Contax camera and Sonnar lens combination is capable of taking pictures of astounding sharpness and depth. Getting critical focus performance, in most cases, requires only the most minute of adjustments. But these adjustments can only be performed when the lens that will be regularly used with the camera is available. When the customer includes the normal picture taking lens with the camera body, when it is submitted for service, a ZTS Camera Focus Tester is used to evaluate the actual performance of the lens/body combination. If only minor adjustments are required to obtain critical focus performance, these are performed at no additional cost. But it is possible this evaluation may disclose that a full lens servicing is required to obtain this scientific instrument level of performance.