Sections:

Servicing A Zeiss Contarex Body

A Couple of Contarex Warnings

Lenses:

This section applies only to the ContaREX lenses and DOES NOT apply to the Contax I, II or III, IIa or IIIa Rangefinder cameras nor does it apply to the ContaFLEX line of 35mm SLR cameras or the ContaFLEX TLR..

The only exceptions to these Contarex lens warnings are the Contarex 250 mm Olympia Sonnar, the 180 mm Olympia Sonnar, the two Zoom lenses, the 35mm Schneider, the Bellows Tessar, and the 21mm Biogon. All other Contarex lenses are the object of the following warning sections.

A General Warning:

The Internet is full of self-help sites providing "advice" about do-it-yourself camera and lens repair. Repair 'manuals" are regularly sold on Ebay. I hear from people regularly who have been become victims of these sites and other media wrongness resulting in damaged equipment.. My advice is simple. If anyone wants to enjoy these as an innocent form of entertainment there's no harm in this; but attempting to repair, service or modify your equipment using these instructions is a more like taking a scalpel and operating on your big toe than it is anything else. My advice is simple: don't do it. Cameras and lenses are complex, full of tricks, made of very expensive or unavailable parts and when a well meaning unqualified, inexperienced, and under equipped person works on them trouble is likely, damage highly probable and success is virtually impossible.

The only advice I can possibly provide to anyone who has worked himself into a corner by being seduced by do-it-yourself instructions, a U-Tube video or any other kind of instructions or advice that has resulted in damage is I cannot base a repair estimate on anything other than a direct examination of the equipment. No amount of verbal descriptions, videos or pictures can provide enough information to provide me with enough information upon which to base a reasonably accurate repair time and expense estimate.

Just the other day I received a very expensive Zeiss lens full of acid mold. When it was taken apart it was full of new wrong grease applied over old dirt and this new grease had fed and supercharged the growth of this mold. There were other abundant signs of recent amateur bad work. The last worker had slathered new grease of the incorrect kind over old mold infected dirty grease and had simply wiped the mold off of the lens surfaces so that the lens looked clean and the focusing control was smooth. The oil from this grease had quickly spread and filled the lens. Then mold quickly returned. U-Tube and other Internet sites are fueling a lot, and I mean A LOT, of bad amateur incorrect and dangerous lens work these days.

It is normal when examining a lens prior to purchase to check the operation of the focusing and aperture controls. It is not possible to examine a lens for its optical quality. These days a lot of people are doing their own lens servicing to "improve" the feel of the focusing and aperture controls of a lens they intend to sell. This gets a better price for the lens. But the real purpose of the lens is optical and it is its optical performance that is the most important thing in the long run. The use of the wrong grease combined with incomplete cleaning result in incomplete work that makes a lens feel good temporarily but with it's optical quality as it was to begin with.

A word About Lens Grease:

Lens manufacturers do not sell the greases they use to lubricate the lenses they make. These are only available and used only when their lenses are returned to them for adjustment, servicing and repair. Many lenses are no longer serviced by their makers and so original grease is not available for them. In many cases the lens maker is no longer in business or in the lens making business.

When a lens is designed the metal alloys and other focusing helical thread characteristics are aimed at the use of a particular grease. This grease is then custom manufactured for the lens maker by a lubricant specialist manufacturer. These compaines typically have very large mnimum order quality requirements and may no longer provide grease made using the original formula provided to the original lens maker.

An old lens may have an absolutely wonderful focusing feel and the goal of many do-it-yourself lens fixer uppers is to dupliate this. But this is a mistake. The reason an old lens has a wonderful focusing feel is the lens grease is at the end of its life. When lens grease ages it releases its oil. When this process starts the oil will sit in a thick film on the grease solid components that stick to the focusing helical threads. This layer of old oil imparts a very light and smooth feel to the focusing control; but this does not last long. Once the oil moves on into the lens what is left are the solid grease components which are sticky and give the focusing control a stiff feel. The goal of a fixer upper is to get a nice light focusing control feel. This always means the use of a very light grease and this always means a low disassociation temperature and a short disassociation age.

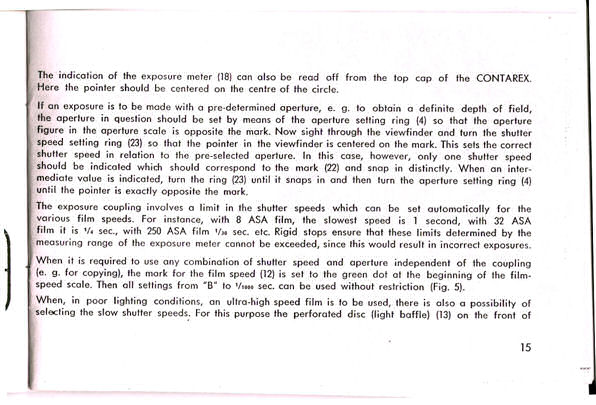

There are some people selling Lens Grease on Ebay that is made in Japan for very large amounts of money. This grease is actually lithium sewing machine grease that has been repackaged. It is not suitable for many lenses. The Nikon Co. did use a super high quality custom made lithium grease in its cameras and lenses; but they did not sell it. It's white, just like any other lithium grease and so it's easy to mistake any ordinary hardware store lithium grease for it.

All greases are a mixture of solid components and an oil. All grease formulas are trade secrets of the grease maker. The purpose of the solid components are to hold the oil. It is the oil in the grease that provides the lubrication and prevents wear. All greases have a "disassociation" temperature and a "disassociation" age. These are the temperatures and the age at which the solid components no longer hold onto the oil and release it. When this happens the oil moves into the lens. A lens maker will know these values for the grease it uses. The problem with all greases used in lenses is that the higher the disassociation temperature and the longer the disassociation age the thicker the grease is and the heavier the focusing feel of the lens focusing control will be. All greases available for use by the do-it-yourselfer come off of Ebay our out of a hardware store. None of these are suitable for use in lenses. The reason for this is shown in this picture:

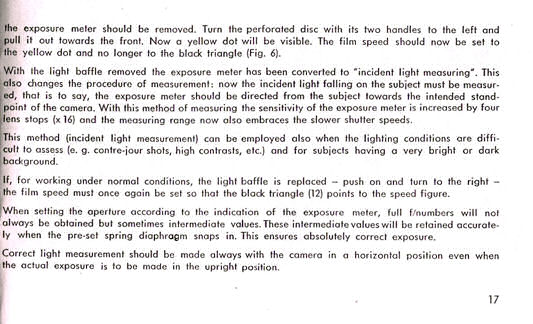

This is a highly magnified picture of a tiny spot the lens owner found had suddenly developed in a very expensive lens he had recently purchased on Ebay. This is a mold spot but not just any kind of mold. It is acid producing mold. This kind of mold feeds on the oil film that is on the lens surface resulting from oil released into the lens by the focusing grease. The acid released by this kind of mold will etch and ruin the coatings and eat into the lens glass very quickly. When this lens was taken apart it was possible for me to identify the particular grease used when this lens was "serviced" prior to sale. Its name is "Selvyt Clock Grease". This grease is made for clocks and it is very light so it gives a very good and light focusing feel. But it has a very low disassociation temperature and a very short disassociation age. It is also very good food for mold as you can see. The grease used in this lens gave up its oil in about six months then it took about three months for the mold spots to appear. This is when the owner contacted me about the lens..

The one and only way to obtain a lens grease that is both safe and effective is to have it custom made at an original custom lubrication maker. This costs thousands of dollars but there is absolutely no other way. There is no grease sold by watch or jewelers maker supply stores, hardware stores, or on the Internet that are suitable for use in lenses. Years ago I paid the price and bought a very thick lens grease and a thin lens grease from the same maker who made grease for Zeiss. These are the same greases as were provided to Zeiss by them. They are compatible with each other and can be mixed together so for each lens overhauled here it's possible to make a mixture of them that has the correct lightness and the correct lubricating properties to provide both the best possible focusing control feel and to prevent premature wear. A lens with a lot of use wear needs a grease that is a better lubricant to prevent wear in the future. A lens that is better preserved can use a lighter grease to get a better focusing feel. All old lenses are not new and so each needs a custom approach to the best lubricant for it. This particularly applies to Contarex lenses. They have aluminum-to-aluminum focusing helical threads and this is an inherently dangerous metal combination from the standpoint of rapid wear and other forms of permanent damage.

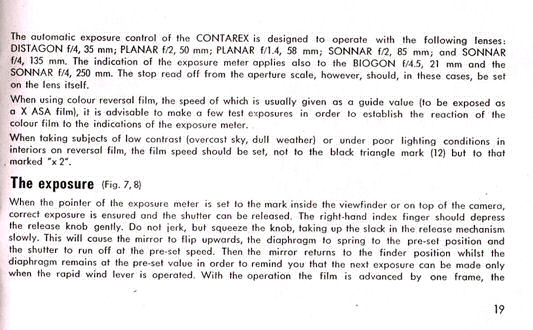

A good high quality lens grease is also formulated by the maker to prevent mold growth. This is not true of other greases like Selvyt Clock grease or sewing machine grease..

When a lens grease releases its oil this oil will eventually move on into the lens and coat everything in the lens before moving on and coating the exterior of the lens. This external oil layer of oil is the reason so many old lenses look good. Just wipe an old lens with some windex and you'll see the oil film go away and can see the real condition of the lens. The big problem with this oil film is that once it is on the lens surfaces it ruins the optical performance of the lens elements. Lenses must be absolutely clean in order to bend the light the way they are designed to do. An oil film changes the optical properties of the lens but not in a good way. A lens fixer-upper never takes the optical part of the lens apart. Why should he? He's not interested in the quality of your pictures; he's interested only in his profit on the lens sale. If a lens looks clear enough to a fixer-upper then it's good enough for sale to the victim. A complete lens overhaul must always involve the complete cleaning of each and every lens element in the lens; but this is a lot of very skilled work that you won't find in any U-Tube video.

A. Lens Warning 1:

I have been contacted by an ever increasing number of people running into trouble while "servicing" Contarex lenses recently asking me for advice about how to get out of trouble with a lens in progress. Many people are putting themselves into the Contarex lens servicing business or "upgrading" them prior to sale to get a better price. There are also innocent U-Tube victims taking screwdrivers to their lenses after having been seduced by a U-Tube video that makes everything look simple. What I've been told by these workers allows me to conclude that these lens "servicing's" are always confined to work to make the focusing mechanism of the lens lighter and smoother. The aperture control system is ignored because Contarex lenses have no aperture control rings to worry about and taking the lens part of a lens is a risky thing to do.. This makes "serving" a Contarex lens low optical risk because the lens part of the lens can safely be ignored by these workers and left in original condition. The result of this is the lens will have a tremendous tendency to produce over-exposures when it is mounted on a Contarex body. This very strong tendency of the lens to be responsible for over-exposures is, for the most part, blamed incorrectly by the camera owner on the camera body shutter or light meter.

These are the reasons why the refusal to completely clean the lens part of the Contarex lens when it is "serviced" leads to over exposures:

First a little background:

The purpose of this warning is to explain why it is absolutely necessary for any Contarex lens you intend to use on a Contarex body must absolutely be completely properly cleaned and adjusted; including most importantly the lens aperture control system and all of its parts.

A. The Contarex put Zeiss out of the camera business. The reason for this was the very high return rate of Contarex cameras for warranty service. The service centers were overwhelmed with cameras returned by their professional owners. The service centers were overwhelmed and they could not solve the problem of the cameras producing over-exposures. In the camera repair business there is one and only one way to solve a the problem of too many returns and this is to go out of business.

The Contarex was made for sale to professionals. It was far too expensive for amateurs. Back then professionals primarily used slide film. At that time slide film had a very narrow exposure latitude. In order to obtain a slide exposed good enough for professional publishing use the film had to be exposed within 1/10 f stop of the ideal exposure. The Contarex could not reliably provide exposures with this extreme degree of accuracy. The main reason this exposure accuracy could not be provided is the aperture control system in the lens could not operate fast enough.

In order for the Contarex to provide accurate and reliable exposure accuracy the automatic aperture control in the camera body must shut the lens aperture to the selected f stop before the shutter begins to open. If this does not happen the result will be an over-exposure or variable exposure across the focal plane because the aperture in the lens will not have fully closed to the selected f stop before the shutter opens and closes. The amount of over-exposure depends upon how fast the aperture closes and the shutter speed acting together. The faster the shutter speed the faster the lens aperture must close before the exposure. The faster the shutter speed the greater the degree of over-exposure.

My experience over the past 20 years overhauling Contarex lenses is that most Contarex lenses will produce over-exposures unless they are very carefully corrected. This experience is that all lenses being sold today are far more liable to produce over-exposures and larger over-exposures than the were when they were new. Here is why:

The spring in the camera body that operates the lens aperture control is tensioned when the camera is wound. The higher the resting tension of this spring the more force is needed to push the camera winding lever. If too much force is needed to push the winding lever to its stop the more likely the lever is to not be pushed to its limit stop. This makes the camera liable to refuse to release the shutter when the release button is pushed. This is because the Contarex shutter has very accurate and tight incomplete wind exposure prevention interlocks. These are designed to prevent shutter speed unreliability due to incomplete winding. This puts a limit on the allowable resting tension of the aperture operating spring and this tension limit is low enough to make friction in the lens aperture control system very important to exposure accuracy.

The relatively low level of force provided by the lens aperture operating spring in the camera body results in the aperture control system in the lens needing to operate with almost no friction and absolutely no hang-ups.. The more friction or reluctance in the lens aperture system the greater the amount of over-exposure the lens will produce.

The Contarex camera body does not have a manual f stop control feature. It is completely automatic. This design decision places complete reliance for exposure accuracy on the ability of the camera and the lens to work together so that the selected f stop is obtained in the lens before the shutter opens. In most cases the camera shutter and light meter is very good and this means the most common cause of over-exposure is reluctance, friction and/or hang-ups in the lens aperture control system.

There are four reasons for a lens aperture control to become loaded with excess friction to the point where overexposures are produced:

1. An oil film on the aperture blades. All old Contarex lenses with un cleaned aperture blades suffer from this and have a sticky oil film binding the aperture blades together. The only reason to open a Contarex lens to clean and grease the focusing threads is stiffness of the focusing control ring. A stiff control ring is due to hardening of the original grease Zeiss used at the factory. When this grease ages and hardens it releases its oil into the lens and the solid grease components remain behind making the focus control stiff. The released oil is sticky. It's deliberately made to be sticky so that it will hold onto the grease solid components. When it is released into the lens it makes things sticky. The only opening into the optical part of the lens is where the aperture control operating lever passes through the lens cartridge. This means the sticky oil coats the aperture blades first and most. When the oil is first released the aperture blades will appear wet and the oil can easily be seen. But, in time, the oil will move on and the aperture blades will appear dry but they will still have a sticky layer of oil on them. This sticky oil binds the aperture blades together. These blades have a lot of contact surface area so all it takes is a tiny amount of oil to produce a lot of operating friction and the aperture control system in the lens becomes harder to operate.

2. Original factory aperture control plate slot or other dimensional problems. The Contarex lens assembly workers at the factory did not understand how important it was to ensure the aperture system in the lens operated with an absolute minimum of friction or the severe consequences of a reluctant lens aperture control system. They just put the lenses together. The result of this is aperture control parts were not selected and adjusted or tested with the required amount of care. The consequence of this is a large fraction of Contarex lenses have original factory aperture control systems that require some very careful examination and adjustment before this system will be able to produce reliable exposures when the lens is mounted on the camera body.

The problem with working on a Contarex lens aperture system and its parts is the people with the courage and taste for risk to do this work need some very rare eye-to-hand coordination skills, extraordinarily great patience and experience with the Contarex system. There are no parts available so working on Contarex lens aperture parts is always high risk. Taking apertures apart and putting them back together is always an acquired taste. It also requires a number of special tools that must be made and cannot be purchased. But with all Contarex lenses today aperture cleaning, adjustment and testing is absolutely necessary. The problem is many people can grease focusing threads but extremely few people are born with the rare necessary inherent talents necessary to work on apertures.

3. Use wear and tear. The aperture control system is just like any other mechanical thing. its parts are subject to wear with use. It is entirely possible for a Contarex lens that has been used by a professional in the past to have made so many exposures that it is simply worn out. These lenses require the most delicate eye-hand coordination, perceptions and judgment to be identified and to be satisfactory corrected. Huge patience is necessary. I've had lenses that have taken days to get the aperture control system right; days of the most delicate possible work.

4. Design limitations. I am sure that if the lens designers had realized just how important the operation of the lens aperture control system was to overall customer satisfaction with the camera system that the aperture control system would have been much more carefully designed to eliminate friction and sources of hang-up. In all Contarex lenses the aperture control system is a very simple system and this renders it liable to operating reluctance from a great number of possible causes. It would have been much better for everyone if the lens aperture control system was designed using miniature ball bearings; but it wasn't and this leads to all kinds of friction and hang-up problems that can be very difficult to identify and correct.

Here is how you can test a Contarex lens for yourself. This is a very easy test:

1. Mount the lens on the camera and release the shutter. This will close the lens aperture to the f stop value set on the camera body control..

2. Set the aperture at the smallest aperture for the lens. This will vary from lens to lens. Note the size of the lens aperture opening.

3. Cock the camera and set the shutter at 1/1000 speed.

4. Remove the back from the camera.

5. Hold the camera so you can view through the shutter. Aim the lens at a bright light.

6. Release the shutter and view the size of the light dot. Do this several times viewing the focal plane from edge to edge and not just in the center. Do this at least 10 times.

7. If the size of the light dot is larger than it should be or if its size varies from side to side there is too much reluctance and friction in the lens aperture control. This means the lens needs a complete overhaul.

8. Perform this test at various aperture settings to detect any hang-up or uneven friction in the lens aperture control system.

B. Lens Warning No. 2.

The Contarex lenses have become very popular with people using adapters to mount them on modern digital cameras. For the most part these new Contarex lens owners, being inexperienced in film cameras, have no idea of the risks entailed in putting a 50 year old lens into regular use. There is a great danger of complete loss of the value of the lens in this. All Contarex lenses have a hidden built-in self-destruct that can happen suddenly and without apparent warning. This problem is the result of the lubricant used by Zeiss when the lens was assembled and also by the particular aluminum alloy used to make the focusing helical threads. This aluminum alloy is extremely highly susceptible to friction welding. Friction welding is metal welding that happens due to friction without heat. It will occur when clean aluminum bare metal is rubbed against itself. When the focusing threads of a Contarex lens become friction welded there is no possibility of repair. The focusing assembly is welded permanently and cannot be separated non-destructively. There is no lubricant or treatment that can separate the moving parts that have been friction welded together. A friction welded focusing assembly in a Contarex lens is permanently ruined and there are no spare parts other than donor parts lenses and these have disappeared from the market. The lubricant used by Zeiss was supplied by a lubrication company in Germany that is still in business. I contacted them to inquire about obtaining a quantity of this lubricant. They replied to say that the lubricant is no longer available and was originally made of a product called "shin oil". This is oil distilled out of the shin bones of cattle. The problem with this lubricant is that a lot of it was infected with a very slow growing mold at the Zeiss factory or when it was manufactured. The lubricant is composed of shin oil and thickeners. The mold slowly consumes the oil and does not consume the thickeners. The time frame for the action of the mold to completely consume all of the shin oil in the lubricant is ending right about now. Just how long it takes for the mold to consume the shin oil depends upon the storage conditions of the lens. A lens stored in warmer wetter conditions will have lubricant that deteriorates faster than one stored in cold and dry conditions. When all of the oil is eaten by the mold only the thickeners remain and they are not a lubricant and not only do they not prevent friction welding, they promote it.. Friction welding can take place in about one to three turns of the focusing control. It happens so suddenly it surprises the lens owners. The most dangerous thing you can do is to try to loosen up a Contarex lens whose focusing action has become sluggish. This is the sure sign the mold is at or very close to the end of its work and that the lens is susceptible to friction welding. I recently purchased three 135mm Contarex lenses whose action is sluggish. The next time their focusing controls will be moved is when they are disassembled and then only after their focusing threads have been lavishly drenched in special oil.

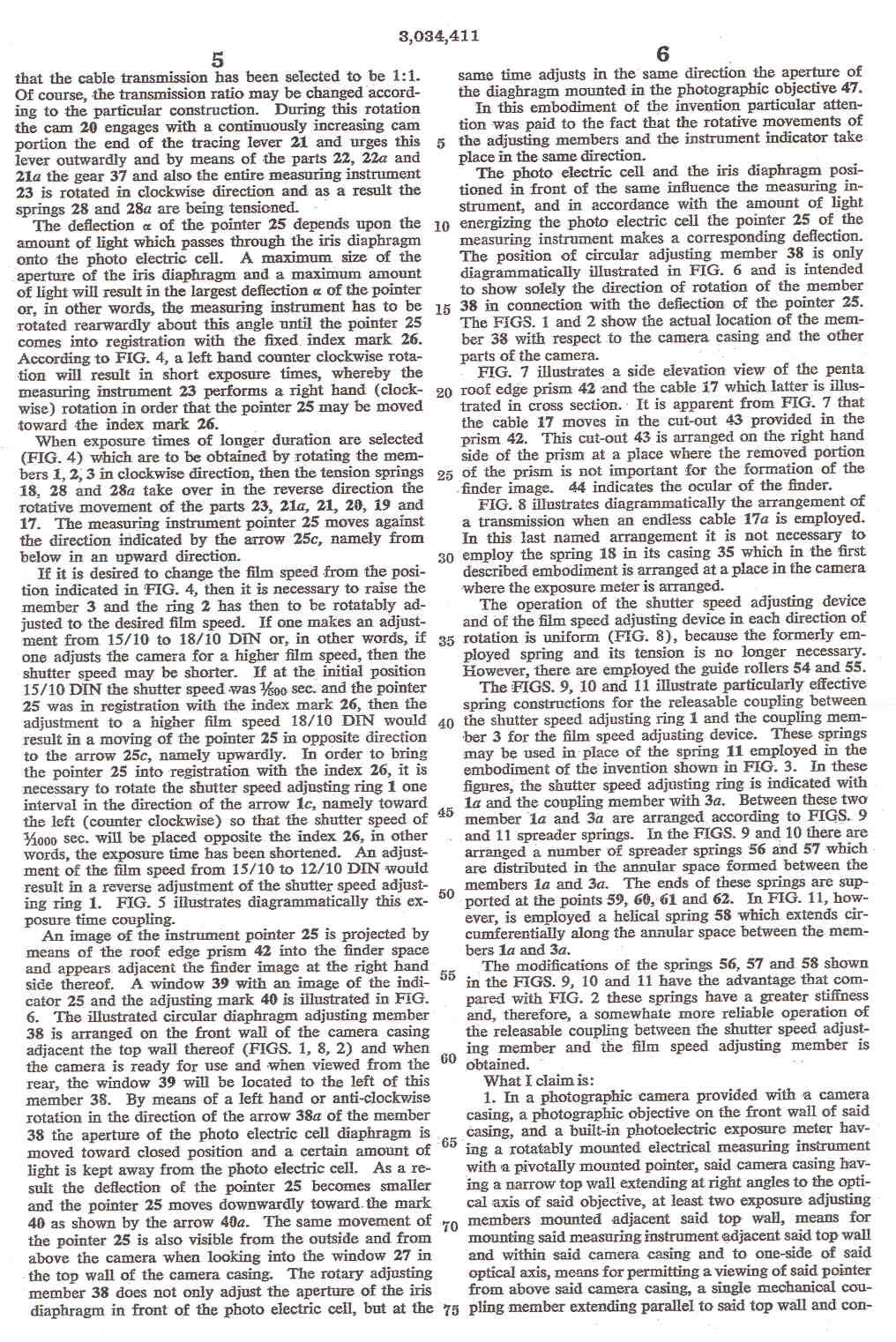

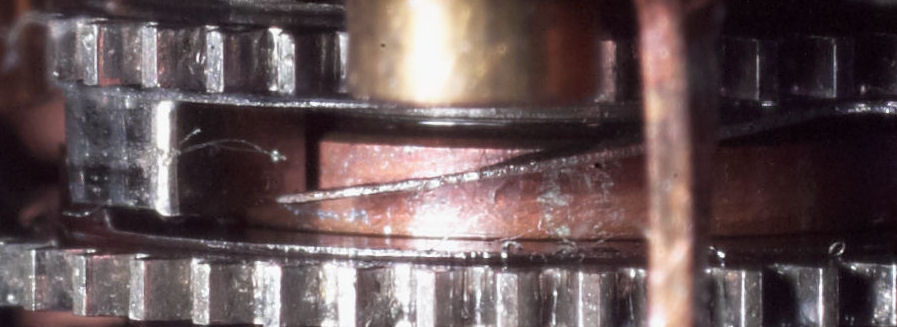

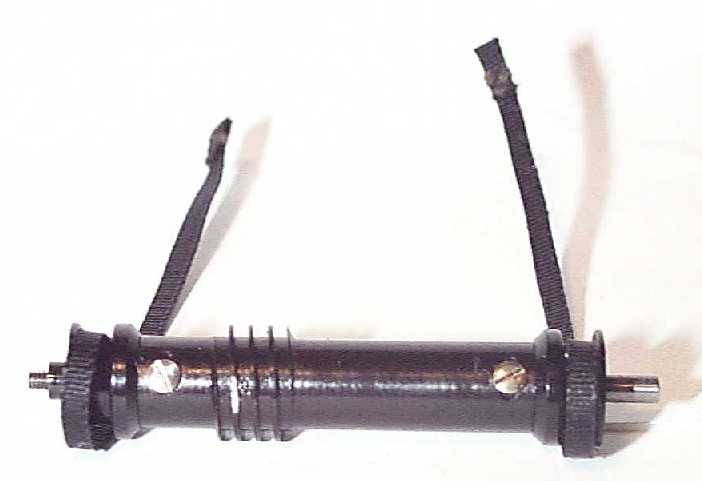

This is a picture of the seized friction welded focusing helical of a Contarex 135mm f.4.0 Sonnar lens. The large blackest part attaches to the focusing ring. You can see on the top the bright aluminum where the set screws scratched their attachment points when the owner used force to try to get the lens focusing control to move. You can see how the original black anodizing of the male threads has faded due to wear and the action of the acid produced by the mold as it consumed the lubricant. It took only two turns of the focusing control from 1 meter to infinity to permanently ruin this focusing helical set. You can pay $1600.00 for a 55mm f1.5 Planar and then have it turned into a complete ruin in about 30 seconds. The same thing can happen to any other Contarex lens because they all used the same aluminum alloy and the same lubricant that is susceptible to mold growth.

The original manufacturer of the Zeiss lubricant originally used in the Contarex has manufactured and supplied me with a large quantity of a modern synthetic lubricant that serves the same purpose but it is not susceptible to mold growth. The second problem with the particular aluminum alloy used in the Contarex lenses is that it needs a special lubricant to prevent premature wear and friction welding. The particular aluminum alloy chosen by Zeiss must have a specially prepared lubricant in order to prevent very rapid premature wear. Zeiss originally hard anodized the focusing threads, but this treatment does not last forty years as you can see in the photograph above. All of the Contarex lenses I have seen have had patches of threading where the hardened anodized portions have been worn through to bare metal and this bare metal is where the friction welding happens. All of the Contarex lenses that I have seen that have been serviced recently have been lubricated with ordinary vaseline grease; the kind you can buy in a drug store. This will prevent friction welding but it will not prevent rapid premature wear. All of the lenses lubricated with vaseline grease have contained vaseline that is filled with bright shiny aluminum wear particles. Vaseline causes the surface of the aluminum to undergo a process called "galling", this is where tiny flakes of metal chip off of the surface in response to friction. The Contarex lens is a very special thing made of very special materials and it demands that only the proper lubricant be used in it.

The Contarex Body:

When you buy a Contarex there are two things you cannot know and which cannot be known until the end of an overhaul. The first of these is you cannot know how long the camera has been stored fully wound. When a Contarex is fully wound all of the springs in the camera are fully tensioned. Springs will permanently loose their strength over time if they are kept fully tensioned. A Contarex that has been stored for 20 years fully wound, and most of them have been stored fully wound for at least 20 years, is one that cannot possibly be restored to 100% factory shutter speed accuracy. This always shows up in the 1/1000 speed which is reduced as a result of long term storage caused strength reduction to the two shutter curtain springs. There are no replacement parts. The second unknowable thing is the state of wear to the shutter speed controller. The more it is worn the slower the final achievable 1/1000 speed will be. It is possible to clean, lubricate and then properly adjust the shutter speed controller but it is not possible to restore it from the state of wear that it is in. An overhaul will stop the wear and will protect it from future wear. The two factors of the loss of shutter curtain strength and shutter speed controller wear contribute, in my experience, to a possible after overhaul 1/1000 speed varying from 1/330 to 1/800 in most Contarex cameras.

The Contarex camera is very complex. It is extremely difficult and time consuming to adjust to extract from it the maximum performance potential when it is in an advanced state of wear, if the camera you buy happens to have been defective from the factory or if workers over the past 45 years or so have done serious internal damage to it.

It is not possible for me to both remain in business and offer a performance guarantee on this camera line. In most cases my experience with this camera is the best that can be done is to completely disassemble the camera, thoroughly clean, assemble, lubricate and then adjust the camera so that it is as reliable and accurate as it can possibly be, and be protected against continued excessive wear due to dirty and unlubricated parts. There is no performance guarantee on any part of any Contarex camera I service. Your only guarantee is that I will do my very best work on it and will not hold back any available resource that is available to me to restore your camera to its highest level of performance given its state of wear and its maintenance and storage history.

This is all there can be with this camera because most of them were very hard used in professional service, then when they became worn to the point they were not reliable enough to produce income for the professional owner they were sold onto the amateur market where they have circulated for decades up until now. Zeiss made the exterior of the Contarex to be extremely resistant to the effects of use, wear and aging and so it is impossible to tell how restorable one may be from an external examination. It is only when most of the work has been done on servicing a camera and the final adjustments are being made that the degree of performance restoration that the camera is capable of becomes evident.

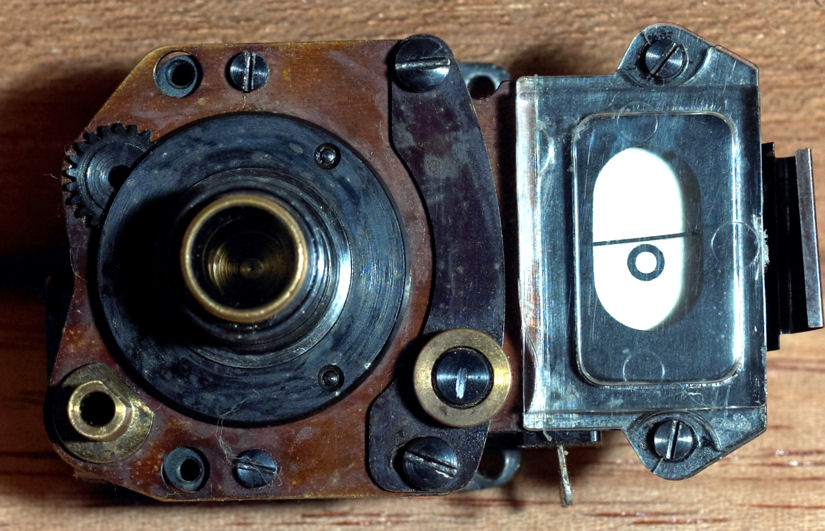

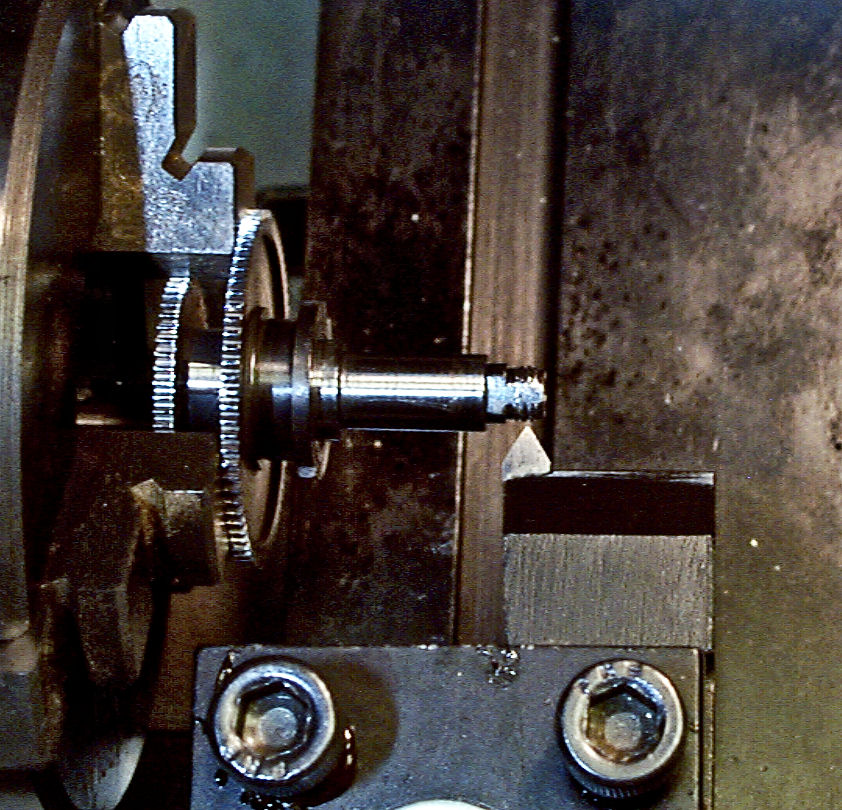

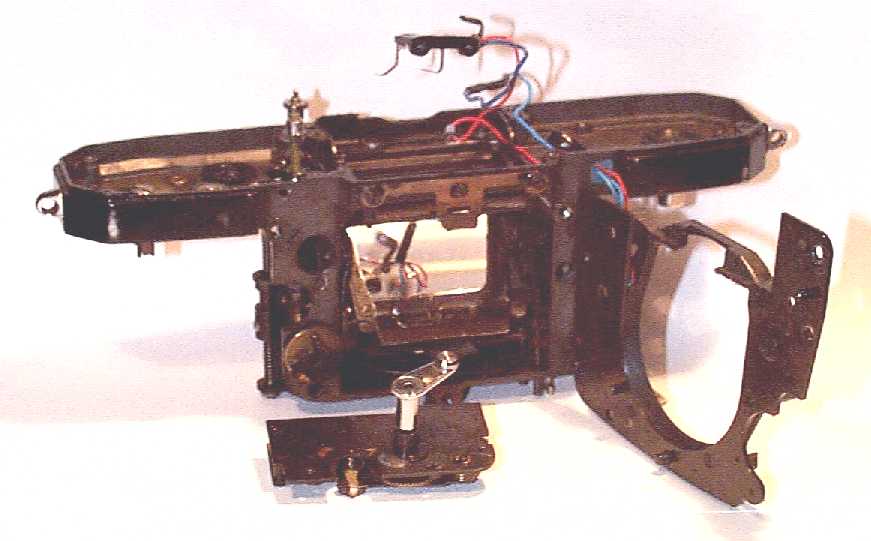

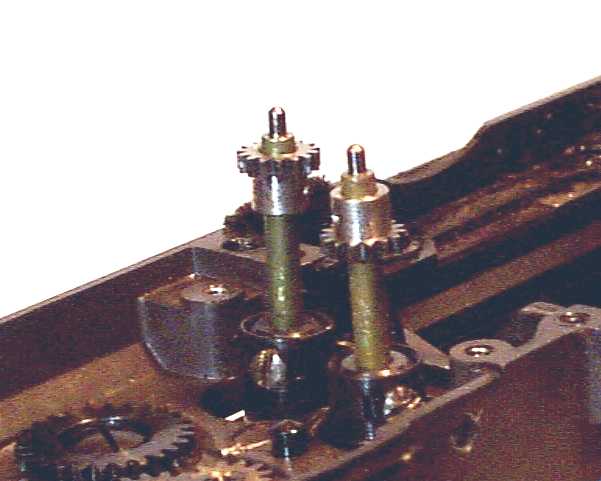

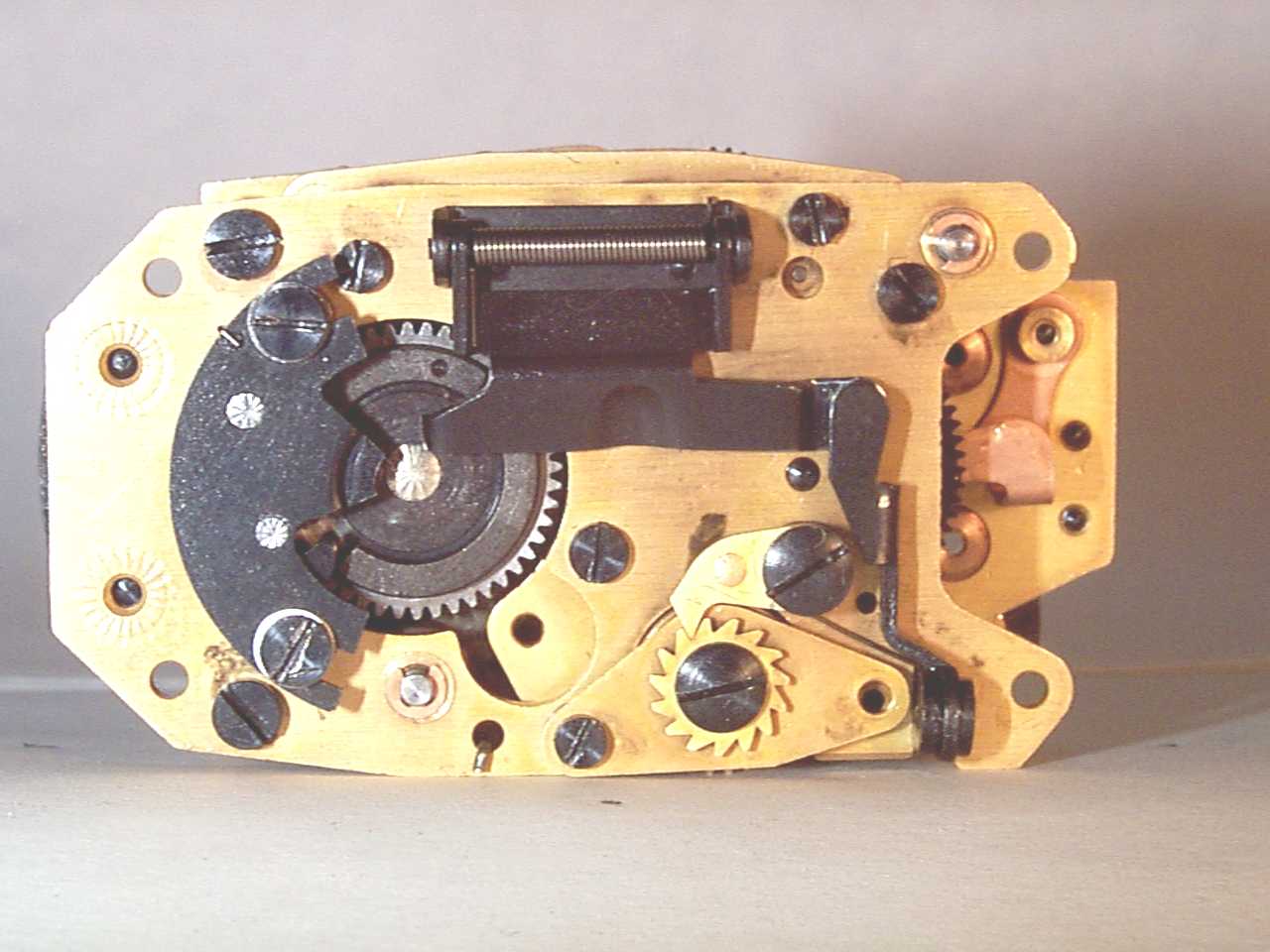

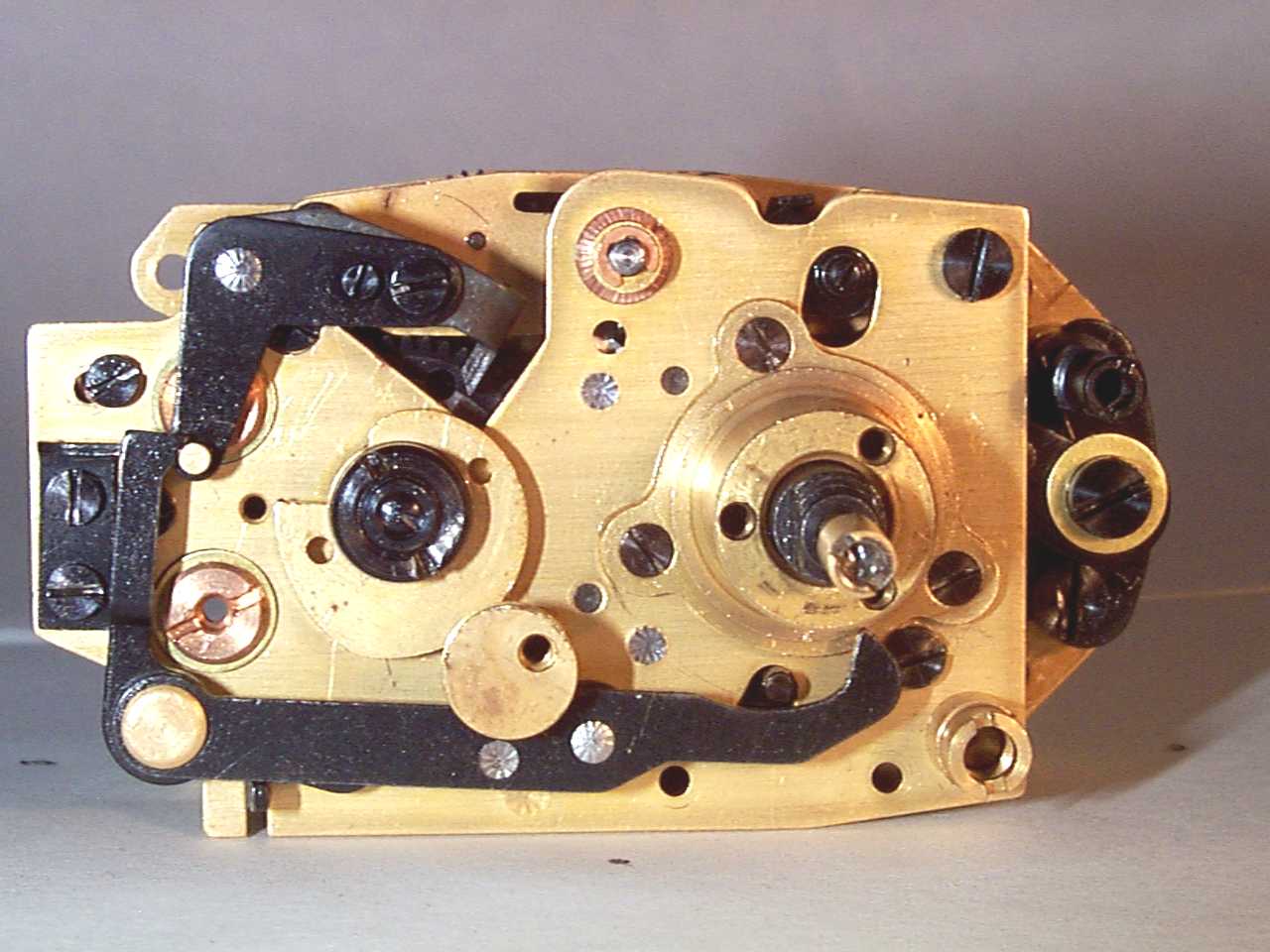

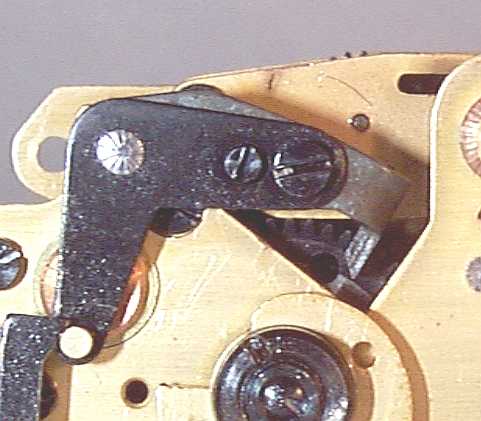

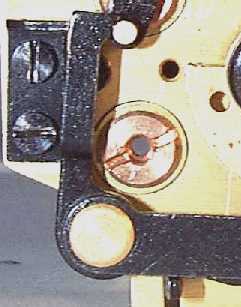

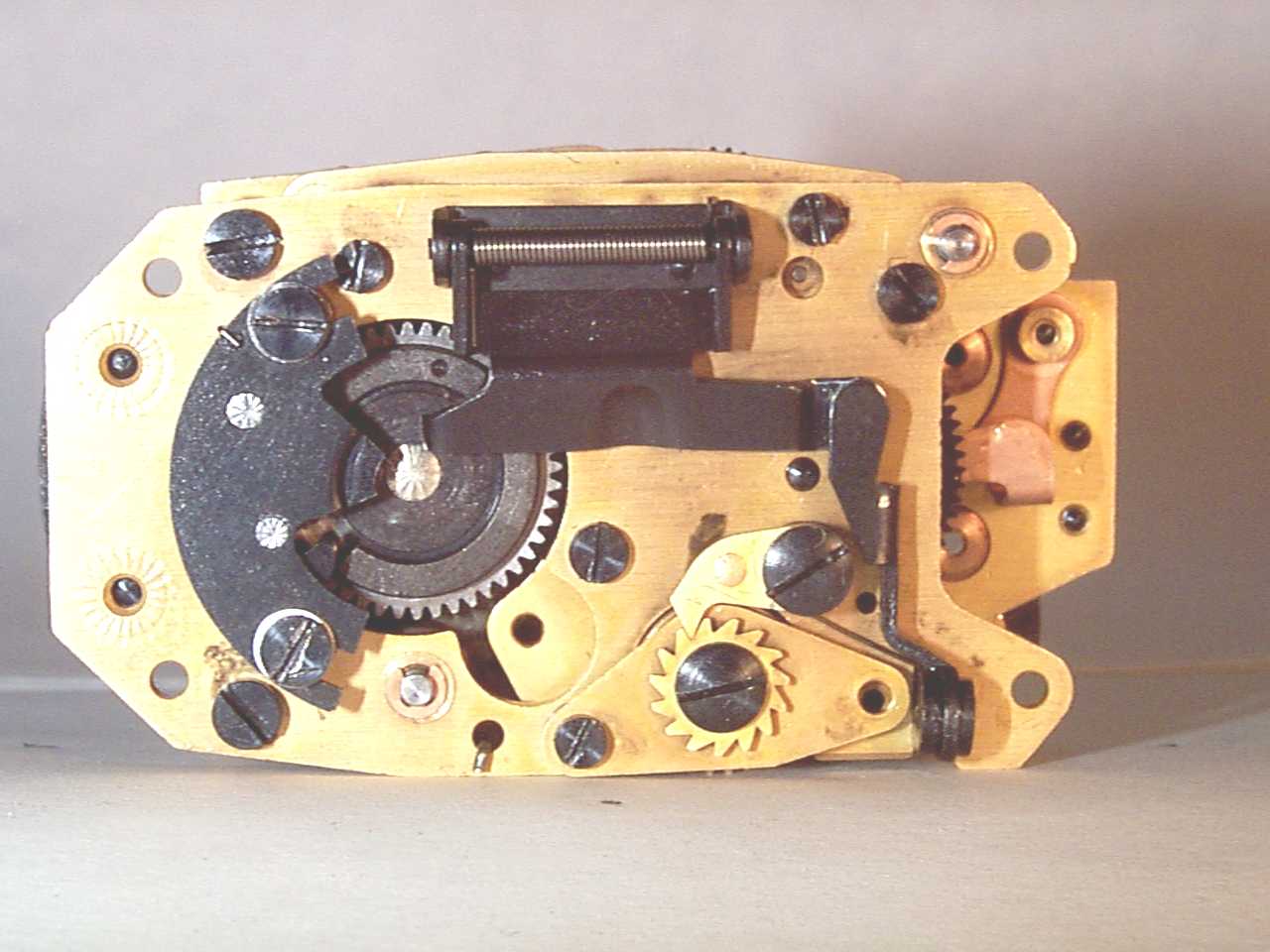

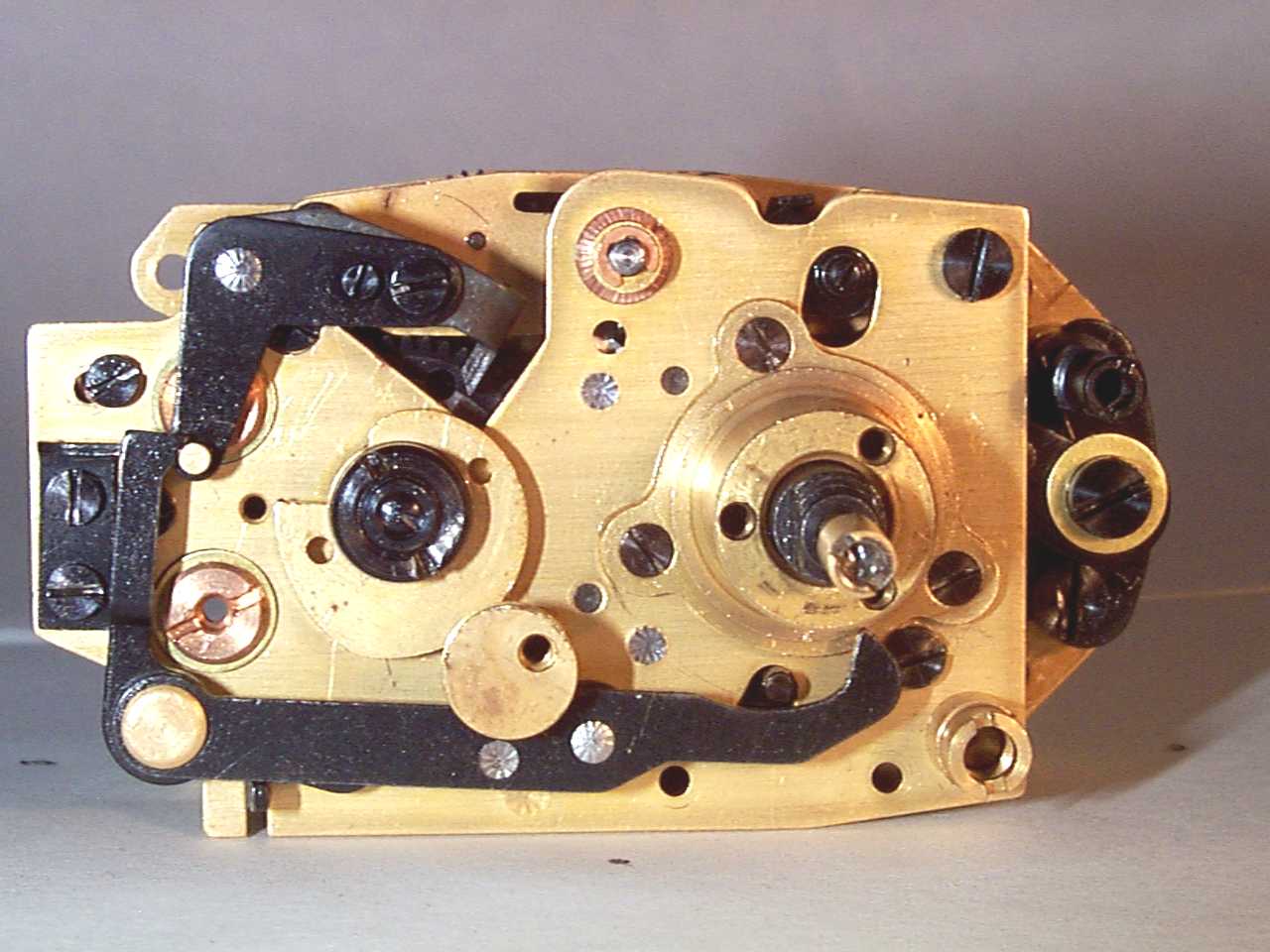

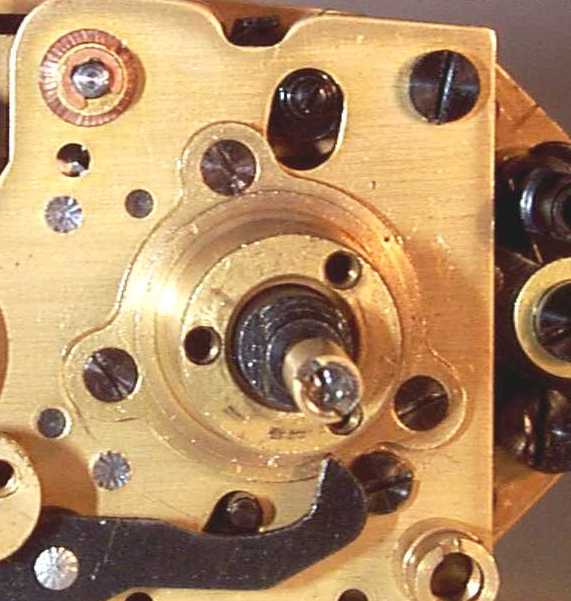

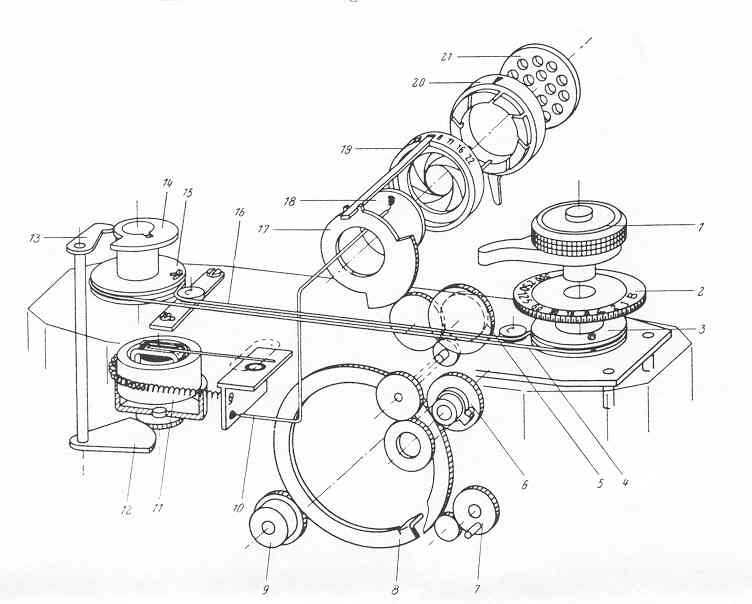

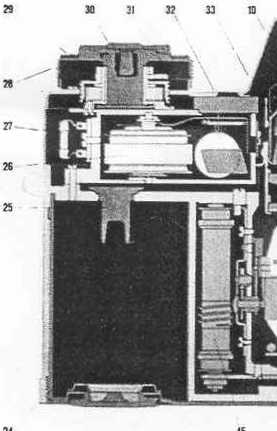

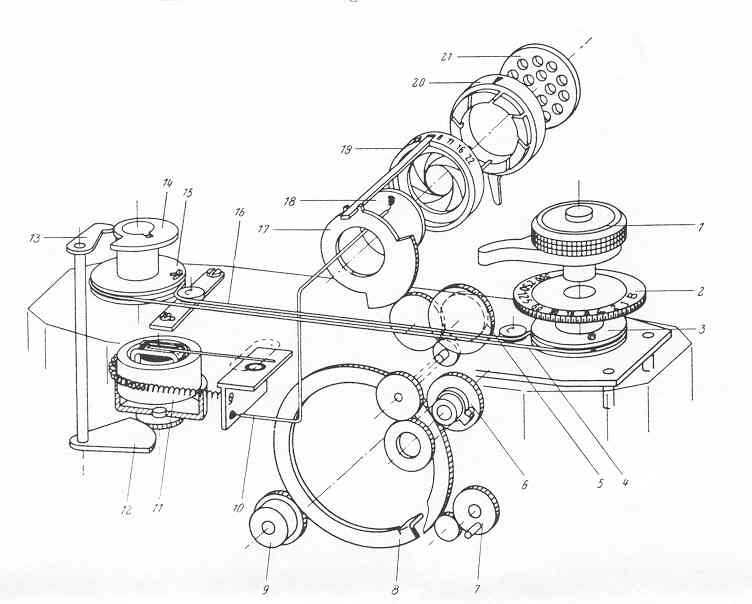

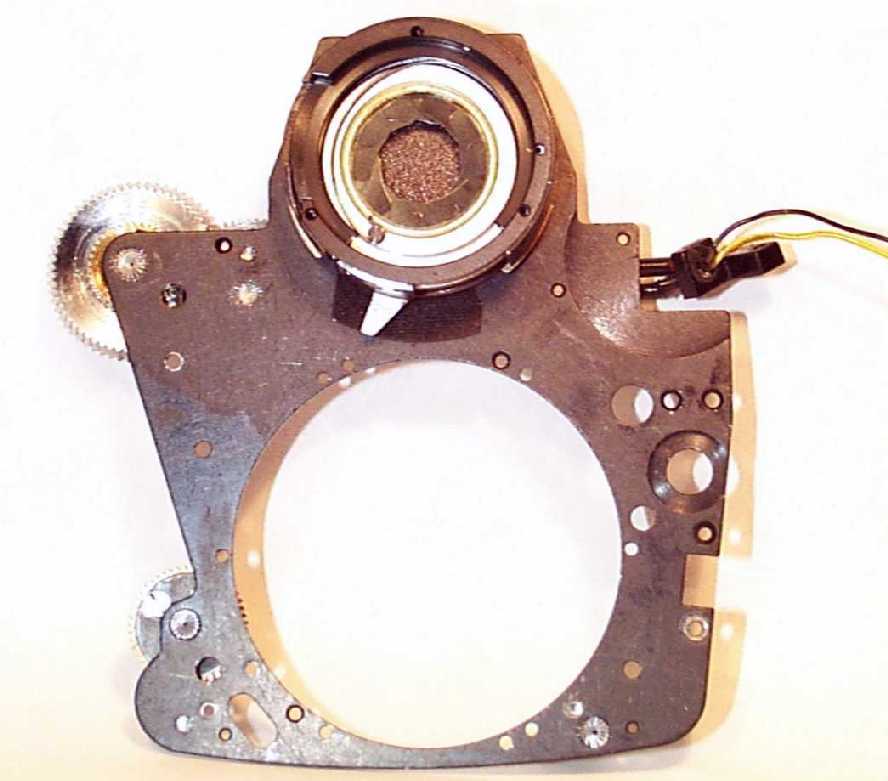

There's one more thing to consider and this is that the chances are very good the Contarex you buy may never have worked properly to begin with. This runs contrary to modern expectations but it is true. The Contarex put Zeiss out of the camera business because it's return rate for warranty service was too high. The following pictures illustrate this far better than mere words can. These pictures are of a Zeiss manufactured Contarex special tool. It is a the camera winding knob part of the wind tool used to wind and adjust the camera while it's top is off the camera body. The left picture shows the tool from the side and the right picture shows the tool from the inside where it mates with the camera winding shaft:

You can see that the tool has been used up over and over again. The hole for the shaft has been rounded and then been hammered back into usable shape with the use of a chisel and a hammer many times to the point where today it is worn out and not usable because the metal has been made too thin. This tool came from the Zeiss Official Repair Center in Canada. There cannot have been a lot of Contarexes in Canada. This tool was used up when the camera was new and was being actively sold. This tool was used by technicians who had limitless inventories of repair parts and access to factory advice. They had also been sent to Germany to be specially trained on the Contarex. This tool got used up because the camera did not live up to the expectations of its owners and could not be made to meet their expectations completely.

The BIG and uncorrectable ownership problem with the Contarex is that it has always been one of the most expensive cameras. it was expensive to buy when it was new and it's price today is more than high enough. The cost of an overhaul is very high because of all the labor involved. People naturally expect that when you pay a lot you should get a lot and this means a lot of stuff or a lot of quality. The Contarex is not a lot of stuff and so the way things go is it is normal to expect that it should be exceptionally accurate and reliable above and beyond the merits of less costly cameras. Unfortunately, it is not as mechanically good as its price causes one to believe. The one place in the Contarex where the quality is vastly higher than the high cost would indicate is the lenses. They are the greatest 35mm Lenses ever made and in order to get to use them with film you have to live with the lack of perfection in the Contarex body.

The Contarex is a fine camera. With an updated light meter and a full overhaul it will take great pictures and be very reliable. But it was not and cannot be made to be the perfect camera because it never was the perfect camera.

Before considering sending your Contarex for service please read the following sections about your model. Consider carefully that your camera, even though from the outside it may appear to be in mint condition, may have been effectively used up and may require very difficult, time consuming, and expensive repairs to restore to its maximum potential. Zeiss used the highest possible quality materials in the Contarex. The exterior has almost unimaginably high quality thick chrome plating on top of thick high quality brass, the highest quality leatherette and thick amber based paint. All these combine to make the Contarex exterior and so it is normal for a very highly mechanically worn out camera or one that never worked right to begin with to show virtually no external signs of wear. Consider also that the Contarex was a camera system designed and priced for professional use. It is a law of the photographic jungle that high priced professional cameras marketed to and used by professionals do not get sold into the used camera market until they are no longer reliable money makers, have taken many thousands of pictures and are impossible to restore to like new condition. Very few Contarex cameras were sold to amateurs and used gently because the were just so tremendously expensive when they were new.

My experience with the Bullseye camera has been that I have not yet seen one Bullseye that is not in a very bad state due to old sticky grease and/or bad work done on it in the past.

The Secret of the Contarex Body As It is Today Explained:

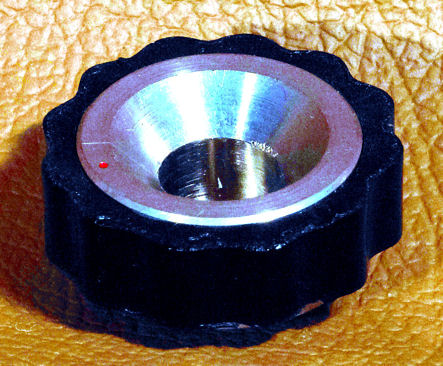

The main modern problem with the Contarex camera body is the reason it's mechanism is so well preserved and this is explained by this picture. It is a picture of the NASA Space Maneuvering Unit used by Major Edward White during the first American space walk during his Gemini flight in 1965. He held it in his hand and used gas vented from it to allow him to move in space.

In the beginning of the American space program there was a huge problem with lubrication. At that time there was no such thing as "Lubrication Science" as it is known today. There were no synthetic oils and greases. Everything was petroleum based and came out of the ground. Back then lubrication technology was primarily the tightly held trade secrets of the makers of oil for car engines and clocks and watches. NASA and Zeiss knew nothing. It was quickly discovered at the start of the NASA space program that In the high vacuum of space ordinary petroleum based lubricants would quickly evaporate and clean metal tended to self weld and stick together. The solution was to invent a new lubricant that could withstand the extremes of space travel and prevent clean metal from self welding in a high vacuum. A lot of money and effort was spent developing this lubricant. The solution was found in industry. Molybdenum disulfide was used in high temperature forges and stamping machines used in heavy industry. The grease that came out of this search is well known today and it is in every car. It is molybdenum disulfide wheel bearing grease that is a thinner version than the type used in industry in 1965. This is what was used in machinery intended for use in space such as the stripped down Contarex Special body mounted on the Space Maneuvering Unit (SMU). The SMU was used during the space walk with its Contarex Special attached to it. This association between Zeiss and NASA and the need to produce a Contarex that can operate in the vacuum and temperature extremes of space explains why Zeiss used wheel bearing grease to lubricate all of its Contarex bodies. The use of wheel bearing grease explains why the Contarex cameras are generally very sticky today. It also explains why a Contarex overhaul is so labor intensive aside from the great mechanical complexity of the camera itself. The axle grease is very difficult, time consuming and labor intensive to remove.

Only Zeiss used wheel bearing grease in it's cameras.. All Contarex Bullseye, Professional, Super, and Electronic bodies are lubricated with molybdenum disulfide grease. The problem with this grease is the solid part, the flaky molybdenum disulfide powder does not hold onto the oil that is used to make it greasy. Over time the oil in the grease migrates away and leaves the dry molybdenum disulfide as a solid residue. The solid deposit of molybdenum disulfide is very effective at preventing wear but it's too sticky to allow the very precise camera shutter mechanisms to operate as freely as is needed.

When a Contarex body is overhauled here it is necessary to remove all of the old axle grease from every part of it. Then the camera must be lubricated using a very special modern grease. The grease used in the Contarexes that are overhauled here is manufactured here. It is a mixture of modern German made synthetic lubricant into which a generous quantity of ultra microscopic nanometer sized round diamonds are added. The "Nano" diamonds are so small they can only be seen using an electron microscope. The are completely round and are so small they fill in all the microscopic pores of the metal forming roller bearings that reduce friction, virtually eliminate wear, and increase the accuracy and reliability of the precision machinery containing them. This nano grease is manufactured here using a proprietary process to combine the grease and nano diamonds. Nano diamond powder is very expensive costing about $1000.00 per gram. But a little bit goes a long way. Nano diamonds are an extraordinarily effective lubricant. The special oil used in the Contarex bodies also contains a generous quantity of nano diamonds also produced by a trade secret process.

The Lost Contarex Lenses:

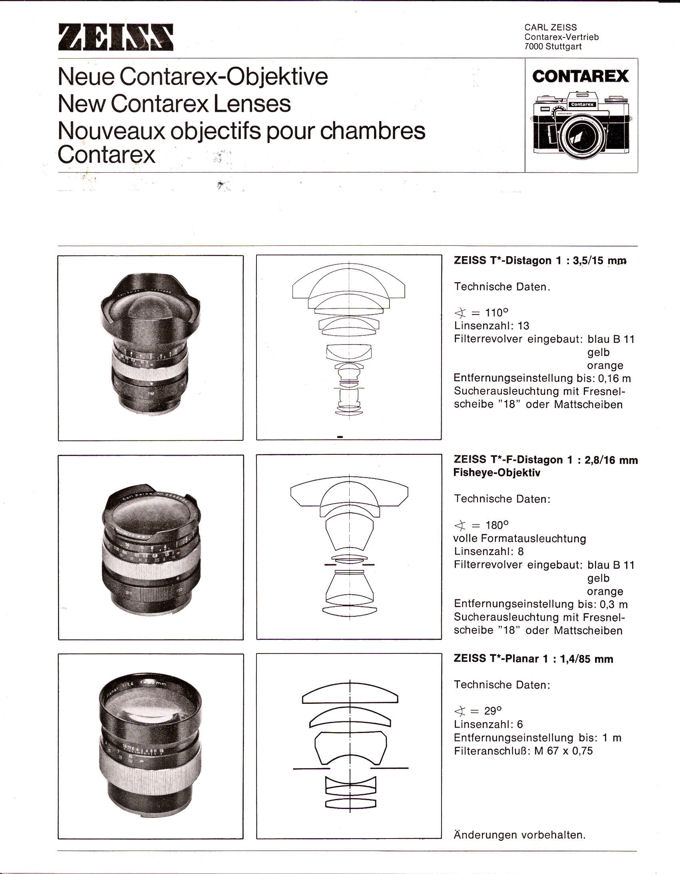

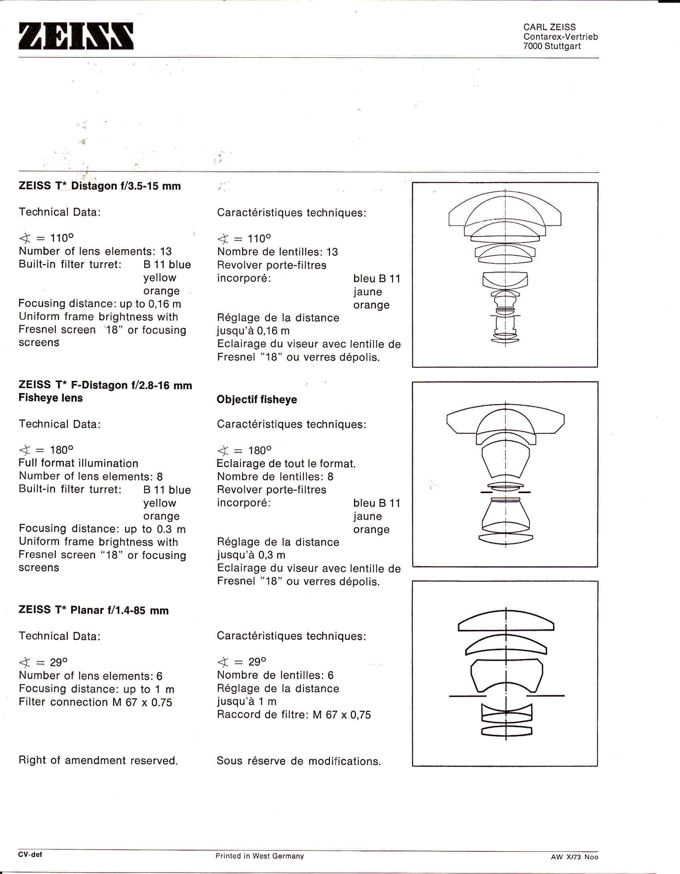

Just prior to the cancellation of the Contarex Zeiss announced the introduction of three stunning new lenses that were never produced except as prototypes Pictures of these prototypes are shown in the following one page Zeiss literature from 1973:

I have seen a Contarex 16mm for sale but not T* coated and have never seen the 85mm T* or the 15mm T* for sale. However, the pictures on this literature demonstrate these lenses were produced as prototypes and still may be sitting on a shelf at Zeiss today. With the renewed interest in the Contarex today it is a shame these lenses are not out there available for purchase.

The Contarex Bullseye

Why the Contarex?

It may seem a little silly to ask, "Why the Contarex", but it is an important question that goes a long way to explain why it is what it is. The shortest, best and simplest answer is "Gold". There are two ways to get gold, you can mine it (lots of dirty work even if you own a gold mine) or you can buy it (clean and easy). Back in the days prior to 1974, when the Contarex was being made, the United States Currency was on the gold standard, but U.S. citizens were forbidden by federal law to own much gold so gold didn't matter to us personally then as it does now. All we were permitted to own then was a small amount of jewelry or to use in manufacturing. There was no such thing as bullion coins or buying gold as an investment like today. U.S. citizens could not buy gold in the USA. But, if you were a sovereign government like Western Germany, you could take all the dollars you got from trade, take them to the U.S. Treasury, and convert them directly into gold bullion. Back then the official gold price was $32.00 per ounce. Gold was a hugely big deal in matters of international trade and most particularly to small countries like Germany who had only one way to get gold and this was to buy it with dollars.

If you were a European government, and you had no gold mines in your country, and you needed gold for international transactions, what would you do? You would probably try very hard to find some product or service that you could market to americans so they would give their dollars (gold) to you. This explains the Contarex and it also provides one of the very good reasons why the Contarex was discontinued the same year the United States went off the gold standard and it was no longer possible to go directly to the U.S. Treasury and turn dollars directly into gold bars.

The Contarex was a wonderful, efficient, and lovely gold mine to the West German government. Zeiss took paint, brass, steel and glass which are very cheap, combined them with local expertise and highly skilled manpower and some electricity, and turned these directly into gold that could be used to finance the reconstruction and prosperity of postwar West Germany. When it was being made a Contarex sold for about 12 ounces of gold at $32.00 an ounce. This is why the Contarex. The Zeiss company is still a big money maker for the German government. This is why even today they print postal stamps with Carl Zeiss and Ernst Abbe portraits on them. This is why even today large silver coins are minted with Carl Zeiss and Ernst Abbe on them denominated in the Deutsche. If you think about it, Carl Zeiss and Ernst Abbe taught the Germans how to turn steel, brass and glass (products of dirt) into gold and everyone's hands are clean and nobody had to go to work in a dirty gold mine like those poor miners today in South Africa.

The simple fact of the matter is that the Contarex is a camera that (would) and could only be made when it could only be paid for in gold; lots and lots of gold. This explains why it is so very very very special and why having one restored is relatively expensive in today's dollars. But if you think of it in historical terms the financing all makes sense.

Suppose you buy a Contarex Bullseye with a 50mm f2.0 Planar for about $700.00 and then invest another $1,000.00 in restoring it to its maximum potential. What are you out? About one and a quarter ounces of gold. Compare this to the 12 ounces it cost to buy originally and this is a bargain. The difference between then and today is that gold costs a lot more dollars to buy than it did back then. There is no doubt in my mind that if Zeiss was to restart production of the Bullseye and build it to the same standards it would easily cost about $15,000.00 in today's dollars. Buying one and having it restored to its maximum potential today for $1700.00 is cheap, cheap, cheap.

A Bit of Advice

Please contact me at superwide@earthlink.net by using this link if you have a Contarex lens that needs service:

Reservations on the waiting list are being accepted for the Contarex line of camera bodies. A small but wide enough supply of original Zeiss new old stock repair parts has been received here. This stock provides the necessary support to allow the provision of the highest possible quality services for the Contarex. Please use the above email link to contact me about your Contarex if it needs service.

The official Zeiss name for the Bullseye is simply the Contarex. Bullseye is a nickname applied by owners. The Bullseye is the most popular model today and so this Contarex page begins with it. Because the Bullseye light meter is always the greatest cause for concern with modern owners the Bullseye section begins with the light meter.

The Four Types of Contarex Light Meters

There are three types of light meters found in the Contarex as they were originally manufactured and one can be upgraded.

1. The selenium type used in the Bullseye. This kind of meter uses a selenium cell. It generates a small amount of electricity when light falls on it. The brighter the light the more electricity is produced up to the inherent limit of the cell, which is about 0.5 Volts. The selenium cell type of meter is characterized by a short range and loss of accuracy in lower light levels. Prior to the development of the modern CDS type light meter there was nothing other than selenium to use in light meters. At that time, with all its weaknesses and problems, selenium was all there was. This is why it was used in the Bullseye. However, a recent development has made it possible to upgrade the Bullseye light meter to fully modern performance. This is described in light meter type 4. below.

There are two kinds of meters used in the Contarex Bullseye. The first version has a circle on the face and the needle is centered in the circle when exposure is correct. The second version has two red arrows and the needle is centered in between both arrows when the exposure is correct. Internally, both meters are the same. The only difference between then is the appearance of the face.

About 55,000 Bullseye cameras were made compared to about 8,000 of all the other models. The Bullseye is the most popular because it is the most affordable and so the first Contarex covered in this section will be the Bullseye.

The three major problems associated with the Bullseye light meter are:

1. Light Meter Inaccuracy. The big problem with the Contarex Bullseye light meter system is the wires that connect the light sensing cell to the light meter. Zeiss used a type of wire that deteriorates with age. This aging causes a great increase in the ability of the wire to conduct electricity. The solution is to replace the original wire with new solid silver wire. Solid silver wire has the highest degree of electrical conductivity and my experience here is it restores the Bullseye light meter to original factory accuracy.

The service to replace the original wire is included in a standard Bullseye overhaul and it is not an additional service.

2. The ASA/DIN selector dial is for lack of a better word pure nonsense. The Contarex light meter was designed for use with film having an ASA or ISO of 100 at the highest. Putting a film speed selector dial on the camera that goes up to an ASA of 3200 was simply for the purpose of marketing the camera back in the early 1960's. This was commonly done back then because everyone was doing it. It was a safe thing to do because films were very slow. The problem is that the film speed dial on the later CDS metered cameras, the Super and the Electronic, are fully capable of handling ASA or ISO 3200 speed film. This has set up a conflict in modern times in peoples minds with the result that there is a prevailing belief the Bullseye light meter should perform to modern specifications and expectations when in fact it cannot possibly do so.

The Bullseye light meter has a feature that is not obvious until you try to use the camera. This is that the lower shutter speeds are blocked the higher the ASA film setting is set on the light meter. If the light meter ASA setting is set at "0" all shutter speeds are available. If it set at 100 then the shutter speeds below 1/8 are blocked and the camera can only be set at higher speeds. This is unique to this camera. It's a method Zeiss used to disguise the inherent limitations of the light meter. There is no way to overcome this peculiar interlock.

3. The Bullseye light meter cell is highly sensitive to side light. The design of the Bullseye type light meter light sensor gives it a huge wide field of view. This makes it extremely susceptible to extraneous light. This effect is particularly strong in diffuse light situations such as overcast days, snowy or highly reflective scenes generally. This wide field of view includes the area of the lens. This makes the light meter sensitive to the finish of the lens and the length of the lens that is mounted on the camera. There is no way to overcome this. The only way to account for it is your experience with the camera teaching you how to adjust your exposures to obtain a good exposure.

These are problems associated with the CDS type light meters used in the Super and Electronic Bodies:

1. The CDS Type using 1.5 V used in the Super and the Super Electronic Type 2: This type of meter uses a cell whose resistance to the flow of electricity changes in response to the brightness of the light. This meter uses a CDS (cadmium sulfide) cell connected to a 1.5 V button battery. Because the power source is a battery this type of meter has a very long range and much better accuracy in lower light levels. It's a fully modern type of light meter whose design has not changed much up to this time.

2. The CDS Type using 3.0V used in the Super Electronic Type 1: This type of meter is identical in function to that using the 1.5V button battery. It's only difference is that it uses the same batteries that are used for the shutter (two 1.5V) to run the meter.

Note that up until 1983 mercury batteries were made and sold for photographic use. Now they are banned. The reason mercury batteries were used is that they had a very nice characteristic. Unlike alkaline cells that lose voltage continually as the are used and age, mercury cells kept their rated voltage right up to the minute they died. This made calibration of equipment using these batteries easy. Today we have to use silver or alkaline button batteries and of these two silver is the better for meter use. But you have to be careful and check your battery voltage from time to time. If you've got a 1.5V battery and its Voltage has decreased to 1.3 V it's time to replace it.

The Contarex Bullseye Selenium Light Meter And How To Use It:

The first thing it is necessary to understand about the Bullseye selenium cell light meter is that it cannot possibly be adjusted or repaired to meet modern light meter expectations. It is a selenium light meter that was designed and made for the extremely slow films available in 1957. Since that time films have speeded up tremendously and selenium light meters have been made obsolescent by the CDS type light meter.

Most Contarex Bullseye cameras being sold today are missing the removable "baffle" that fits over the light meter cell. This baffle was intended to be used to increase the sensitivity of the light meter by being removed in low light conditions. It has about a four f stop effect. But the Contarex selenium light meter was never able to live up to the performance specifications published about it. People who bought the Bullseye quickly found that under normal circumstances the meter would work well in daylight provided this baffle was removed. The result of this is that these baffles got put away, were lost, and most Contarex Bullseyes sold today don't have them.

This is a picture of the back of an original Contarex Bullseye Selenium Photocell from a stock of Contarex parts that recently came my way. As you can see it clearly indicates it was manufactured on January 24, 1958. This shows that Zeiss had made its decision about the size of the cell to be used in the Contarex about a year prior to this date and so the light meter in the Contarex Bullseye is a 1957 era light meter.. The diameter of this cell is unusual and it was custom made for the Contarex:

Here is a Contarex advertisement from 1961. This is about the time it was introduced:

This is what I believe to be the first advertisement for the new Contarex cameras. The date on this is April 1961 and this means that the design of the Contarex probably was finalized about two years earlier sometime in 1959. The important thing to understand about the Contarex Bullseye is that it has a 1957 era light meter in it. One of the great beauties of the Contarex is that the camera exterior design is timeless and appears today to be modern. This appearance can provoke the false impression that the camera is fully modern.

Notice that this advertisement makes it perfectly clear the Contarex has been designed for the "Professional and advanced amateur". Many Contarexes today are being purchased by people who do not have anything near to the kind of photographic knowledge a professional or an advanced amateur would have had back in 1961. Much has been lost since then. The fact the Contarex was intended for professional use means it was designed and manufactured to last in professional use about five years which is how long it's price could have been deducted from federal taxes.

Back in 1961 the state of common knowledge in the photographic community was that there were two kinds of camera users: amateurs and professionals. Amateurs used point and click cameras and professionals used real cameras. Real cameras were not perfect in every respect. People who were real "non-amateur" photographers knew then that you had to test a camera, find its defects, and then work around them to get the maximum number of great shots. Today people expect cameras to produce perfect results all of the time under all conditions. The Contarex Bullseye cannot possibly live up to any expectations other than those that existed at the time it was sold. It had problems with its light meter in 1961 and because films have gotten a lot faster since then these problems have only gotten worse with time .

Recently It has become possible to restore the Bullseye light meter so that it is much better than new in performance with a new generation silicon photocell. If this is done the Bullseye light meter will perform very well to modern expect ions with modern high speed film.. But if this is not done, because the Bullseye light meter was designed and made for use with very slow film available in 1957 the modern user will have to make some adjustments and compensations. These adjustments and the reasons for them are explained in the following.

The Bullseye camera has had a pattern of complaints that have surrounded it in modern times and these all circulate around the light meter. I recently overhauled a Bullseye, installed my last new selenium photocell in it, checked the meter to make sure its performance was within factory specifications, and then thoroughly explored and tested the light metering system. The results were fairly surprising. Later I read the Contarex Bullseye Instruction Manual section on the light meter and in the light of the new knowledge observed that Zeiss had very cleverly telegraphed their concerns about the Bullseye light meter back when the camera was being made.

There are eight things that need to be understood about the Bullseye and it's selenium light meter:

1. The Bullseye is a camera of its time. It was designed for the slow film and the need for bright light of the time. It is a camera designed to use slow film in bright day light or in shade in bright day light. This is opposite to the way things are today with people using fast film in low or moderate light, and so there must be some adjustment in camera operating technique to account for these changes. Back in 1959 when the Contarex was designed, the fastest color film had an ASA (ISO) of 16 and Koadchrome had an ASA of 8. The design of the Bullseye meter made good sense back in 1957.

In 1957 it was common for very high quality selenium light meters to come with booster cells. These booster cells allowed the meters to be used in low light situations. This picture is of a Leica Meter shown in its original packaging with its booster cell on the left..

You can see the booster cell is larger than the meter itself. Translating this up to today it's easy to see that if the Contarex Bullseye with its selenium light meter is going to be used in low light levels or with very fast film, a booster cell should be necessary. Unfortunately Zeiss did not provide the Contarex with the provision to use a booster cell and so the photographer of today will have to make some adjustments concerning how the camera light meter is used when modern high speed films are used in the camera.

When the Bullseye was being made it was standard technique to use "fill in" flash using flash bulbs most of the time. In a questionable lighting situation the technique was to just use a flash bulb and use guide numbers and not use the light meter. In 1965 flash bulbs were the predominant method of flash, bulbs were cheap, and everyone used them all the time. It was standard practice then to always sell a pack of flash bulbs with a roll of film. People did not expect their light meters to be totally accurate under any and all lighting conditions and with any film. It was a standard technique to solve any uncertainty about exposure with the use of a flash bulb.

In 1959, Kodachrome had an ISO of 8 and Kodacolor and Ektachrome had and ISO of 16. The most popular black and white film was plus-x-pan and it had an ISO of 125. Tri-x-pan was available then and it had an ISO of 400, but it was extremely grainy then (unlike today's vastly improved version) and at that time was considered to be more of an emergency use ultra fast film. The Bullseye light meter was designed for use with these slow films. Many people may ask then why does the Bullseye light meter setting go as high as 1600? The reason is that the 35mm camera market was a perfect storm of competition then and marketing was important. The light meter film speed setting dial on the Bullseye goes that high because back in 1961 it had a super WOW factor that helped sell the camera in a very big way that is impossible to understand today.

In 1959 Zeiss manufactured the Contax IIIa rangefinder camera meter. It had a larger photocell than the Contarex Bullseye but it had an ISO setting that went only up to 400. It's a great meter and people use it today without any complaint. Taking the fact the Bullseye photocell is about 2/3 the size of the cell in the Contax meter, It is reasonable to assume the Bullseye meter is probably about half as good as the meter in the Contax. This doesn't mean it's a bad meter. It just means it has limitations that must be taken into account when it is used today and with today's vastly faster films. It cannot be used carelessly or without a good knowledge of its workings. These are the things this section is intended to provide to you.

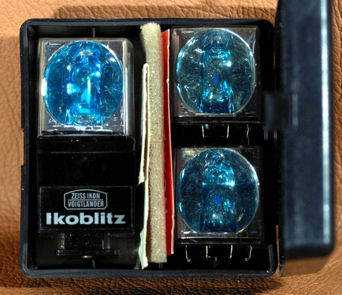

Let me give you a tip. Buy a nice Zeiss Ikotron bulb flash unit. They are cheap and abundant on Ebay. Buy some bulbs to go with it. Use them from time to time. You'll find they are great in an emergency and do a great job when your 're in an exposure pinch. Here's a picture of a handy little Zeiss Ikoblitz flash cube flash. It's tiny and it's plastic case has strap lugs on the back. It weighs about a couple of ounces and is very handy to have. This one cost about $5.00 with shipping included and flash cubes are readily available on the Internet or on Ebay.

2, The Contarex is not a perfect camera. Back in the time when the Contarex was being made Zeiss was in a crisis. The 35mm camera market was in a state of turmoil. The Japanese had just discovered the tremendous power of the process of statistical quality control that everyone uses today. Japanese camera makers were building 35mm cameras and were dumping them below cost on the U.S. market in order to gain market share. The Japanese were cleverly pumping out moderately priced, fully automatic, 35mm rangefinder cameras with large aperture (1.2 or 1.4) lenses, that had the "German" look and these were flooding the market at prices that tremendously undercut equivalent German made cameras.

Zeiss decided to compete by making the ContaRex, "Rex" the King of cameras. But it was too much and it went too far and marketing got involved in design. An example of this is the film speed dial on the Contarex Bullseye. It goes up to 1600. Back when the Bullseye was being made this was an unimaginable speed. The fact is the camera was designed and made for a maximum of ISO 100 and this only in bright daylight (more about this in the following).

Zeiss had to evade patent infringement with the Leitz (Leica) shutter patents. Leica had invented the 35mm focal plane shutter and had it covered with a building full of patents. Leitz sued Zeiss over the shutter in the Contax IIIa and so there was no doubt about Leitz defending its patents. The result of this is that the Contarex is excessively complex and consequently difficult to adjust.

The main thing is that Zeiss made the finest 35mm optics that have ever been made for the Contarex and this is the one and only reason to get one. You can only experience Contarex optics on a Contarex body and it is worth it.

3. The Bullseye light meter has a big problem when used with today's fast films and this is the variable iris over the selenium photocell. Because of this it is best to not use the aperture control, in low light situations, when adjusting the light meter to obtain the correct light reading for a scene. More about this later.

4. All electrical equipment ages. As it ages it becomes slower and less sensitive. The Bullseye light meter is no exception. Because every Bullseye has had a different storage and use history YOU ARE GOING TO HAVE TO PERFORM TESTS AND EXPERIMENT WITH YOUR OWN CAMERA TO FIND OUT HOW IT HAS AGED AND WHAT THE EFFECT OF THIS AGING IS.

5. There is one big thing to understand about the Bullseye light meter and this is that the Bullseye light meter is UNIQUE in its design and IT CANNOT be used like you use a normal hand held light meter. This is explained in much more detail in the following.

6. When a Contarex is overhauled here it is restored to the maximum extent its potential will allow. There can be no guarantee the camera will be restored to like new, absolutely perfect, or a condition that matches the expectations of the owner. Each Contarex has it's own use and storage history and these strongly effect the inherent camera potential when it is presented here.

7. The exterior of the Contarex was made of such high quality materials, and it has stood up to the test of time so well, that even a fully worn out camera will have a good appearance. It is my experience that the actual condition of a Contarex, regardless of the model, cannot be determined from an appraisal of it's external cosmetics. Another thing to consider is that the highest class of camera butchers are well aware of the importance of external cosmetics. They take great care to keep a camera looking good on the outside even while they totally wreck it on the inside.

8. The Contarex has always been an expensive camera. No matter what you do or how you try to gain an advantage a top quality Contarex is an expensive thing. A customer recently sent me a Bullseye he had purchased for $189.00 with the 50mm f2.0 Planar lens. He called it a piece of junk. He was right. It took weeks of careful work and adjustment to undo the effects of bad storage and bad workmanship. In the end the cost was $1300.00 in repair charges and the camera is not perfect because it is incapable of being made perfect. It's the best he can be, and it's certainly worth $1489.00. My advice to you is to be very very careful when buying a Contarex body. There's no way to avoid the fact that the Contarex is an expensive camera and it will always be an expensive camera.

Here Are The Results of My Studies, Experiments and Measurements of the Bullseye Light Meter:

1. The type of plastic Zeiss used to manufacture the selenium photocell cover installed permanently in the camera over the photocell and that is also used in the removable 2X cover selectively absorbs a large fraction of light emitted from an incandescent bulb. The practical effect of this is that the Bullseye light meter cannot be calibrated using a precision light source. The one and only way to properly calibrate a Bullseye light meter is out of doors in sunlight. The camera meter is compared with the result from a precision hand held meter and then set to match.

2. The best method to use when using the Bullseye light meter is as follows:

This advice must be seasoned in accordance with the speed of the film you are using. The higher the speed above an ASA or ISO of 100, the more strongly you must compensate.

a. In direct day light or in the shade of direct day light: Use both the shutter speed dial and the aperture dial to obtain the correct camera settings when using film with an ISO of 100 or below. But test your camera to make sure you understand the limits of this technique. The aperture control may not be accurate at small apertures. You may need to compensate for an inaccuracy that testing has demonstrated is applicable to your particular camera.

b. In low or medium light such as in the shade of high buildings: Set the aperture control at the largest available f stop (preferably 1.4), then rotate the shutter speed dial to center the needle. Once you have an f stop to shutter speed combination If a different aperture is desired decrease the shutter speed by one speed for each f stop the lens is closed from full open. Verify this by testing your particular camera.

c. In the red light of early morning or sundown: The light meter plastic cover absorbs lower light frequencies selectively. This will make the meter indicate more exposure than is actually needed under lighting conditions containing incandescent light or a lot of red light. The meter will not be accurate in these lighting conditions. Apply a correction factor, based upon your testing, or of at least thee to four f stops to the meter reading and close the aperture by three to four f stops or increase the shutter speed by three to four settings. But again, test this recommendation against the performance of your particular camera to obtain the most accurate exposure compensation.

d. If the needle is centered with a speed setting in between speeds set the shutter speed dial to the next highest or lowest marked speed before making the exposure. The factory tolerance of the meter is +/- 1/2 f stop and so this will have no practical effect upon the exposure.

e. Do Your Own Testing. This is the way things were done back in the day when the Contarex was being made. Back then people did not expect absolute shutter or light meter accuracy. It was normal to expect to have to learn the "windage" of a fine camera. People expected that they would test their camera with film and then apply a little adjustment here or there to make things just right based on the results.

I sold fine cameras back in 1965. Back then people would take a roll of film, put it in their new camera, take various shots, have it processed, and then bring the camera back into the store when the film was developed. We would then examine the pictures and negatives and discuss each shot and how it was made and how the camera was used. From this the camera owner would explore the camera and would learn what compensations were needed in particular lighting conditions in order to get the best exposures. This is what you must do with your Bullseye.

f. The meter becomes slower to respond the smaller the aperture setting. This is not a fault of the meter it is a natural characteristic of the selenium coating on the photocell that generates the electricity when light strikes it. As the aperture control is set to a smaller aperture (larger aperture number), the iris over the selenium photocell closes and covers more of the photocell area and the photocell is effectively made smaller and smaller. At f22 the photocell is at least 99% covered and has less than 1% of the area it had when the aperture control was set to f2.0. Selenium has a "memory" that can last several minutes. The smaller the selenium cell the longer the memory. This memory effect makes the Contarex Bullseye meter very very slow to respond to changing light level when the aperture control is set to close the aperture over the photocell.

Here Are The Reasons Why You Want to be Careful and Judicious About Use of the Aperture Control When Using the Bullseye Light Meter.

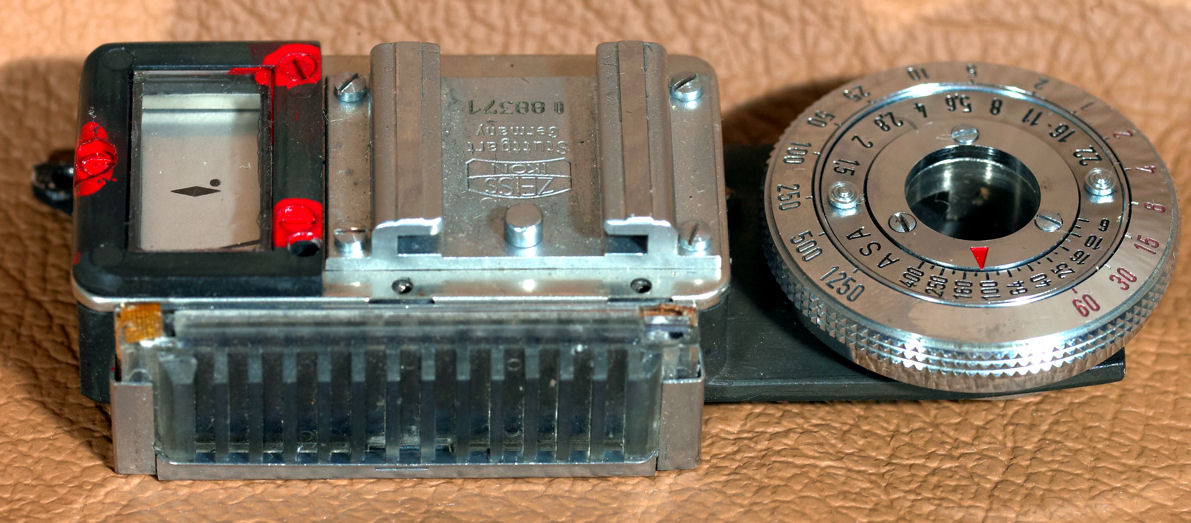

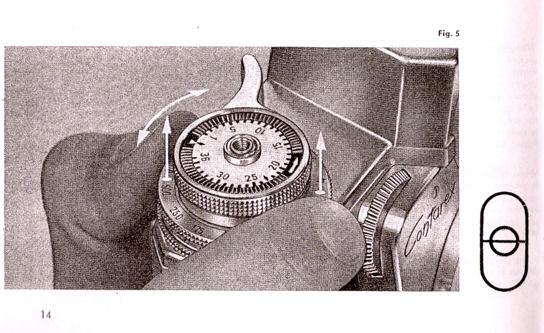

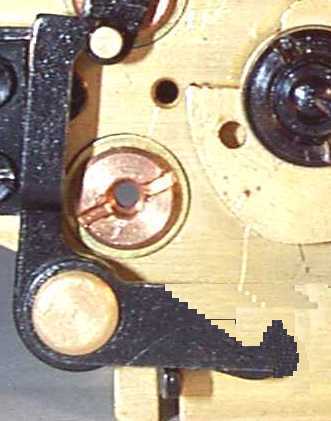

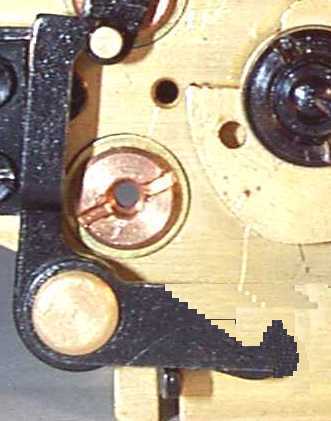

This is a picture of the Bullseye light sensing cell:

As you can see the selenium cell has a movable iris over it. This iris is connected to the camera body aperture control. The iris over the photocell is fully open when the aperture control is set to the largest aperture and it closes as the lens aperture control is moved to a smaller aperture. Back in 1963 this was no problem because the light meter was designed for use with a color film having an ASA or ISO of 16.

The variable Iris has three effects:

1. When the iris closes the amount of electricity generated by the photocell decreases. It is possible, even in bright shade under noon summer sun to have meter accuracy problems with very small apertures of 11, 16 or 22.

2. There is a more subtle secondary effect that only becomes important when the speed of the film being used in the camera exceeds an ASA of about 200. This effect is based upon the simple fact that with selenium cells the faster the film the camera will use or the less bright the light the camera will be used in, the larger the illuminated area of the selenium photocell must be in order to be able to generate enough electricity to move the needle of the meter accurately. In the Contarex, as the iris closes over the cell (which is small to begin with, more about this later), and the dimmer the light level, the lower the maximum effective film sensitivity of the meter becomes. The problem comes when the iris closes to a point where the effective maximum film setting of the meter becomes lower than the speed of the film that is actually in the camera. Back in the early 1960's, when film were vastly slow compared to today's films, this could not happen. But when a normal film whose speed is fantastically fast compared to1963 films, is put into the camera, it's a guaranteed problem.

For the purposes of this section please forget about the maximum film "setting" of 1600 on the Contarex meter speed setting dial. That is an impossible number will be shown later. For each reduction in size of the illuminated area of the photocell by about 33%, the effective maximum setting of the meter is cut in half. For example. Suppose we assume the maximum actual effective maximum speed of the Contarex light meter is about ISO 200. This means that at an aperture setting of 1.4 where the aperture over the cell is fully open the meter is capable of handling this speed. But if the aperture is closed by one f stop to f2.0, the maximum speed of the meter is going to be about 100. This is when the meter begins to show accuracy problems and this is what we see in actual practice..

Now, lets look at the Contarex light meter from a 1961 viewpoint. If we have ASA 16 film in the camera, then at f1.4 the maximum effective setting of the meter is 200, and at f8.0 it's 100, and 5.6 it's 50, at 8.0 it's 25, and at f 11 it's about 12.5. There's no problem here because you would need a bank of massive floodlights to give you enough light so that with ASA 16 film you'd need an aperture of f11. The meter will have acceptable accuracy in accordance with 1960 standards, all the way down to f22.

There's another problem with the iris over the cell. Each change in aperture setting to close the aperture, say f 2.0 to f2.8, decreases the amount of light available to the cell to produce electricity for the meter by 1/2; but the cell voltage does not decrease or increase by a factor of 2 in response to each change in the aperture setting.

3. The effect of the closing of an iris over the cell can result in a non-linear electrical output in response to the closing of the iris. The iris covers the photocell and blocks light from hitting the cell and generating electricity. The more the iris is closed the less electricity is produced. With the iris shut down to it's smallest setting (f22) it is possible in even bright light for the cell to be producing such a small amount of electricity that the meter does not work properly. This is one reason why the aperture control should not be taken to a very small aperture when metering a scene. My tests show that in the deep shade of a sunny day at noon, f5.6 is the lowest setting that should be used. If the ambient light level is lower than this the aperture over the photocell should be kept wide open.

This non-linear behavior was not a problem back in 1960 because film speeds were not that accurate nor was film processing. Back then you were lucky to get a film with an actual speed that was +/- 25% of the value printed on the box. Then there were also variations introduced by processing. I worked in a processing lab in 1966 and the variation in "as developed" film speed was +/- 50%. Adding these inaccuracies up with the +/- 1/2 camera meter tolerance and the camera body +/- 1/2 aperture control setting tolerance means simply that back in 1961 it was impossible to have a camera light meter that is even in the same accuracy ball park with today's modern meters.

The electrical output of a brand new photocell was measured in response to the change in the opening size of the aperture covering the cell. The result was that from f1.4 to f22 the cell voltage decreased from 0.450 Volts at f1.4 to 0.230 Volts at f22. The cell voltage changed by a factor of 2 over a span of 9 f stops. There is a point where closing the aperture by one stop will result in a halving of the cell voltage. You will need to find out this point by testing your particular camera. My experience has taught me that this point, with a new photocell, in bright day light or the shade of bright day light, is between f 5.6 and f 8.0.

Comparing One Zeiss Selenium Light Meter with Another:

It is useful to compare the size of the Contarex selenium photocell to another selenium cell used by Zeiss in a camera that was made at the same time. This is a picture of the light meter used in the Contax IIIa 35mm Rangefinder camera:

You can see it uses a rectangular light sensing cell whereas the Contarex uses a round one. The Contarex cell and the Contax IIIa light meter cells are shown together in the next picture:

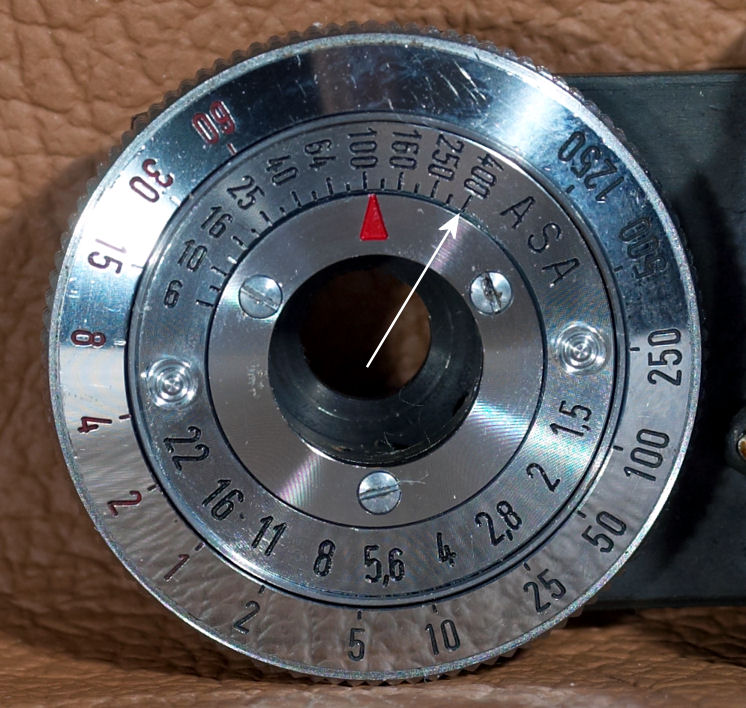

The Contax IIIa photocell has an illuminated surface area of 360 square millimeters and the Contarex cell has 263. The Contax IIIa cell is 96 mm2 larger than the Contarex cell or in percentage is 37% larger. Notice also the maximum ASA or ISO setting on the Contax IIIa light meter is 400 (shown by the white arrow):

There is a big conflict here. The highest Contarex ASA setting is 1600 yet its photocell is smaller than another Zeiss meter with a larger cell whose highest setting is ASA 400.

The only way to resolve this conflict is to understand that at the time the Contarex was designed the camera market was in a turmoil. Competitive pressures were very great and marketing was extremely important. There was no ASA 1600 film available at the time the Contarex was designed and so it was perfectly safe, for marketing purposes, to give the Contarex a highest setting of 1600. But Zeiss could not know back then that as the camera moved through time, and films got faster and faster, that 1600 setting would become a practical problem as it is today.

Because the Contarex photocell is 37% smaller than the Contax IIIa cell it is practical to use this figure to estimate the actual maximum film speed that the Contarex is capable of using with the light meter being used in full accordance with the instructions provided in the Contarex Instruction Manual. In doing this estimation I'm not going to show all of my calculations here because they are too complex. At the time the Contarex was designed the Germans used a film speed scale called DIN and it was based upon the film response curve. Considering the German DIN method of film speed determination a cell 37% smaller should be useful with a meter whose maximum ASA setting is about 1/2 that of the meter using the larger sized cell. This means the Contarex light meter can be safely used, if it is in like new condition, as the instruction manual provides, with a film whose speed is no greater than 200.

If you use a film as fast as ASA (IS0) 200 you're right at the edge of the envelope of Contarex meter design capability. You'd be a lot safer at an ASA of 100 or less. This is why, when you use today's very high speed films, you have to operate the Contarex meter in a way that compensates for the fact this is way out of its design envelope.

Back in 1959, when the Contarex was designed, there was no such thing as a color film as fast as ASA (ISO) 200. an ISO of 32 was the fastest for Professional Ektachrome. With films of this speed the Contarex light meter was being operated very comfortably within its design zone.

The movement of the light meter needle in response to electricity from the selenium photocell IS LINEAR. It can best be understood through the following pictures:

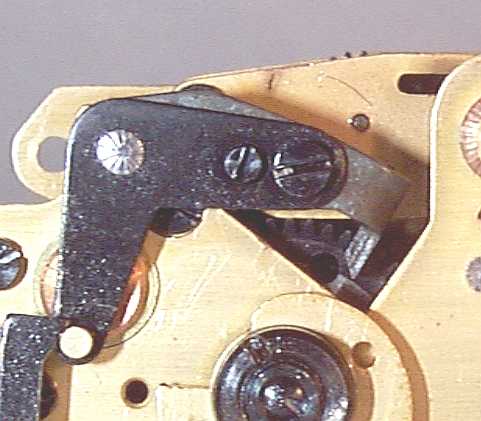

This is a picture of the top of the Bullseye Light Meter:

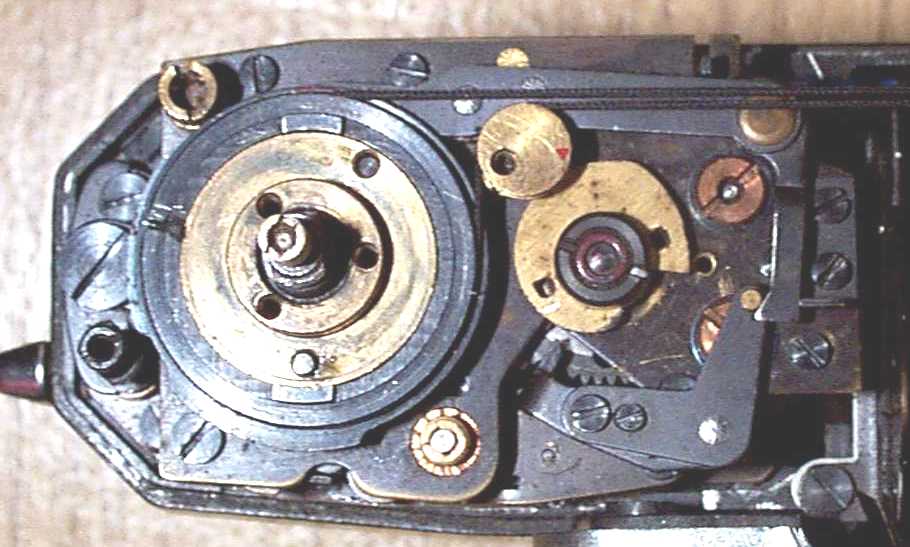

This is a picture of the same meter with the top removed:

The white arrows are pointing to little blockers that keep the needle from moving too far. The very narrow span of needle movement makes it impossible to make any judgment of how far one is away from perfect exposure in the same way one can with a normal hand held light meter.

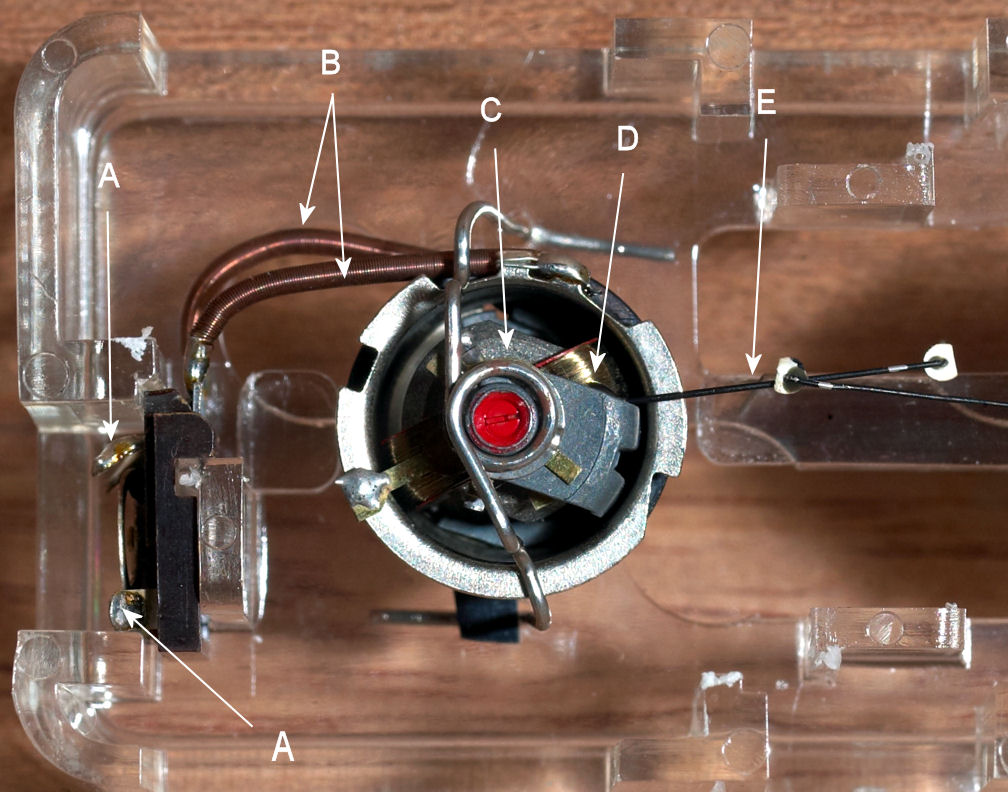

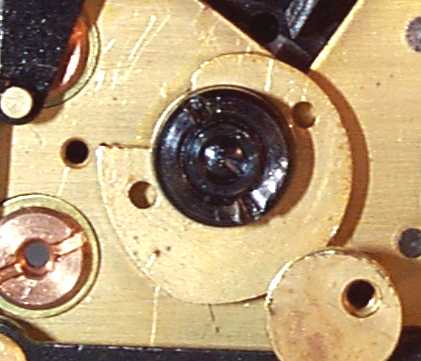

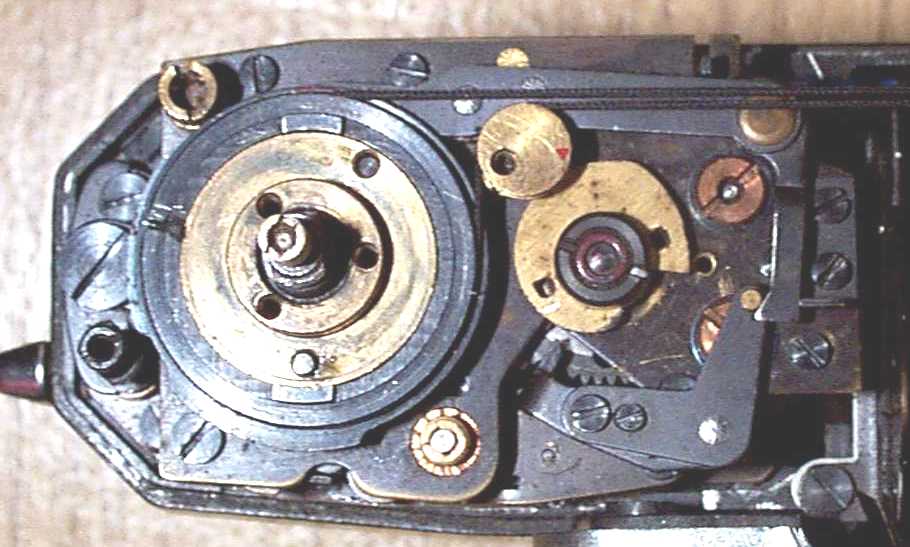

This is a picture of a brand new Bullseye Light Meter Movement. This is the little motor in the meter that uses the cell electricity to move the meter needle:

In this picture the parts of the meter movement (motor) are shown as follows:

A are the electrical connections to the photocell.

B. are the wires between the electrical connections (A) and the tiny coil (D)

C. Is a permanent magnet. The magnetic force generated by the coil (D) acts against the magnetic field from the permanent magnet to generate a force that moves the meter needle.

D. This is tiny coil. The electricity generated by the selenium photocell circulates in the coil and this generates a variable magnetic force that acts against the fixed magnetic force of the permanent magnet (C).

E. This is the meter needle.

The key thing to understand about this part of the camera is that it is tiny and is completely un repairable. If the camera has been stored in a humid environment and the parts of the meter become corroded, or if the camera is stored in a shed where it is exposed to summer/winter humidity and drying out, or if it has been badly shocked or bumped or if it was defective to begin with there is nothing that can be done about these factors.