Zeiss Ikon Contax Camera Repair

A home for your Zeiss Ikon Contax, Contarex or Super Ikonta camera!

Body:

- What Condition is Your Camera In Now?

- What is the Contax?

- Contax Shutter Accuracy in a Camera Today?

- What is Shutter Bounce or Blanking?

- What is the Difference Between a Black Dial and a Color Dial Camera?

- Can a Black Dial Camera be Converted to a Color Dial Camera?

- Can Anything be Done for a Gouged Eyepiece Bezel?

- Why is Zeiss Chrome so Bad?

- Can Anthing be Done for Bad Paint?

- Can I have a Camera Custom Built?

- How Should I Care for My Contax?

- The Illustrated Camera

- Why is Zeiss Chrome so Bad?

Rangefinder:

- The Rangefinder Wheel is Hard to Operate, What is the Cause of This?

- The Focusing Helical Seems to Have a Lot of Clearance, is This Normal?

- Why don't the images in my viewfinder and rangefinder line up right?

- The rangefinder image is badly faded, can it be restored?

- My Pictures are Fuzzy. Is it the Lens or the Rangefinder?

- There is a Defect in the Rangefinder Image, Can this be Corrected?

Shutter:

- Pictures of a Shutter Disassembly

- Pictures of a Shutter Assembly

- Why Does the Color Dial Model Shutter Not Release Sometimes?

- What are Shutter Tapes?

- What is Shutter Capping?

- What is Shutter Bounce?

- My shutter appears bent, what causes this?

- Shutter Cocking and Film Advance

- How do you clear a Jammed Camera?

- Why Does the Self Timer Interfere with 1/1250 Speed?

- How are Shutter speeds set on a IIa or IIIa camera?

Lightmeter:

- The IIIa Lightmeter Explained

- My IIIa LIghtmeter Doesn't Respond to Light At All, Can This be Repaired?

- The Needle on My IIIa LIgtmeter Sticks, Can this be Repaired?

- The Response of My Lightmeter to Light is Intermittent, Can this be Repaired?

- Can the IIIa Lightmeter Photocell be Rejuvinated?

Lenses In General:

- How Should a Lens be Cleaned?

- What Can be Done for a Filter Ring Dent?

- What is an Opton Lens?

- What is a Red "T" Coating?

- What is the difference between a Zeiss Opton and a Carl Zeiss Lens?

- Why are there Bubbles in the lens elements in my lens?

- What is Lens Fungus and What Can be Done About it?

- There is Oil on the Aperture Blades, is this Important?

- Can a Badly Scratched Front Element Surface be Repolished?

- What is Lens Element Separation or Cement Failure and What Can be Done about it?

- Can Nikon Lenses for the Nikon Rangefinder Cameras be Used on Contax Cameras?

- Can Jupiter Lenses for the Russian Rangefinder Cameras be Used on Contax Cameras?

- The 85mm f4.0 Sonnar

Leather:

- Where Can A New Camera Case Be Found?

- What are Zeiss Bumps?

- Can Zeiss Bumps Be Removed?

- Can Damaged Original Leather Be Replaced?

- "Zeiss Bump" Removal from Leather

Emergency:

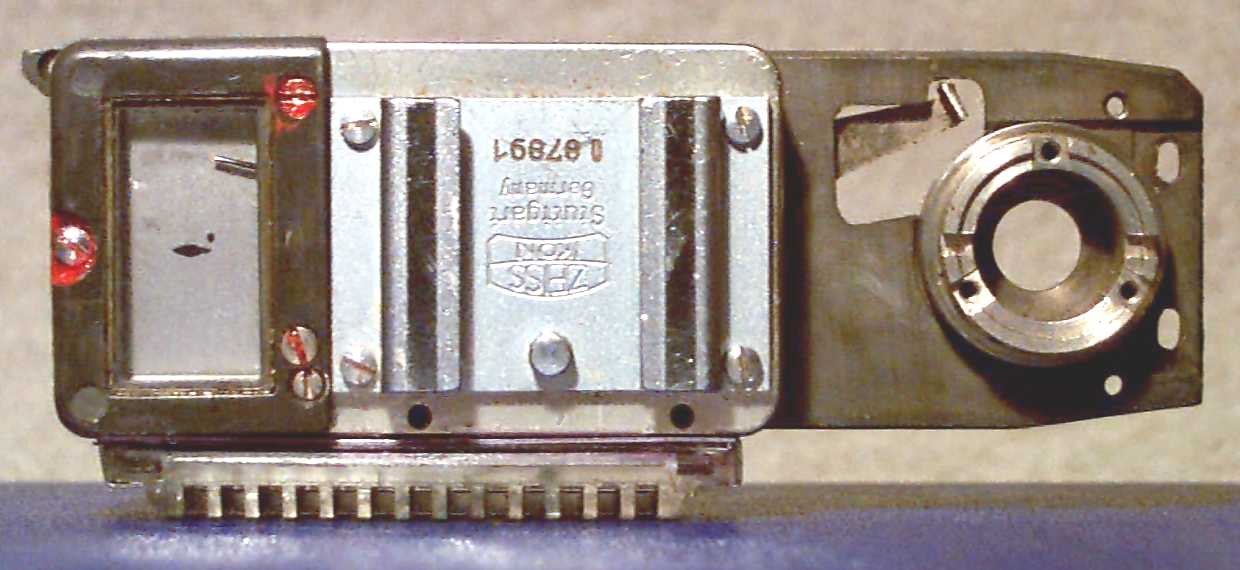

Overhauling A Contax IIA/IIIA Body

It doesn't matter how bad the condition of your Contax IIa or IIIa

is. Chances are

it can be economically repaired to its full inherent performance

potential. The camera overhaul pictures on this page are of the winterization

rebuild of a Contax IIa that had been stored for a very long time in damp

conditions, had originally been defective from the factory and never worked

properly. It had been worked on many times by unskilled technicians

and at some time the winding knob had been forced backwards doing severe

damage to many delicate parts. It was restored to completely reliable

smooth and accurate operation.

It doesn't matter how bad the condition of your Contax IIa or IIIa

is. Chances are

it can be economically repaired to its full inherent performance

potential. The camera overhaul pictures on this page are of the winterization

rebuild of a Contax IIa that had been stored for a very long time in damp

conditions, had originally been defective from the factory and never worked

properly. It had been worked on many times by unskilled technicians

and at some time the winding knob had been forced backwards doing severe

damage to many delicate parts. It was restored to completely reliable

smooth and accurate operation.

What Condition is Your Camera in Now?

The First Assumption:

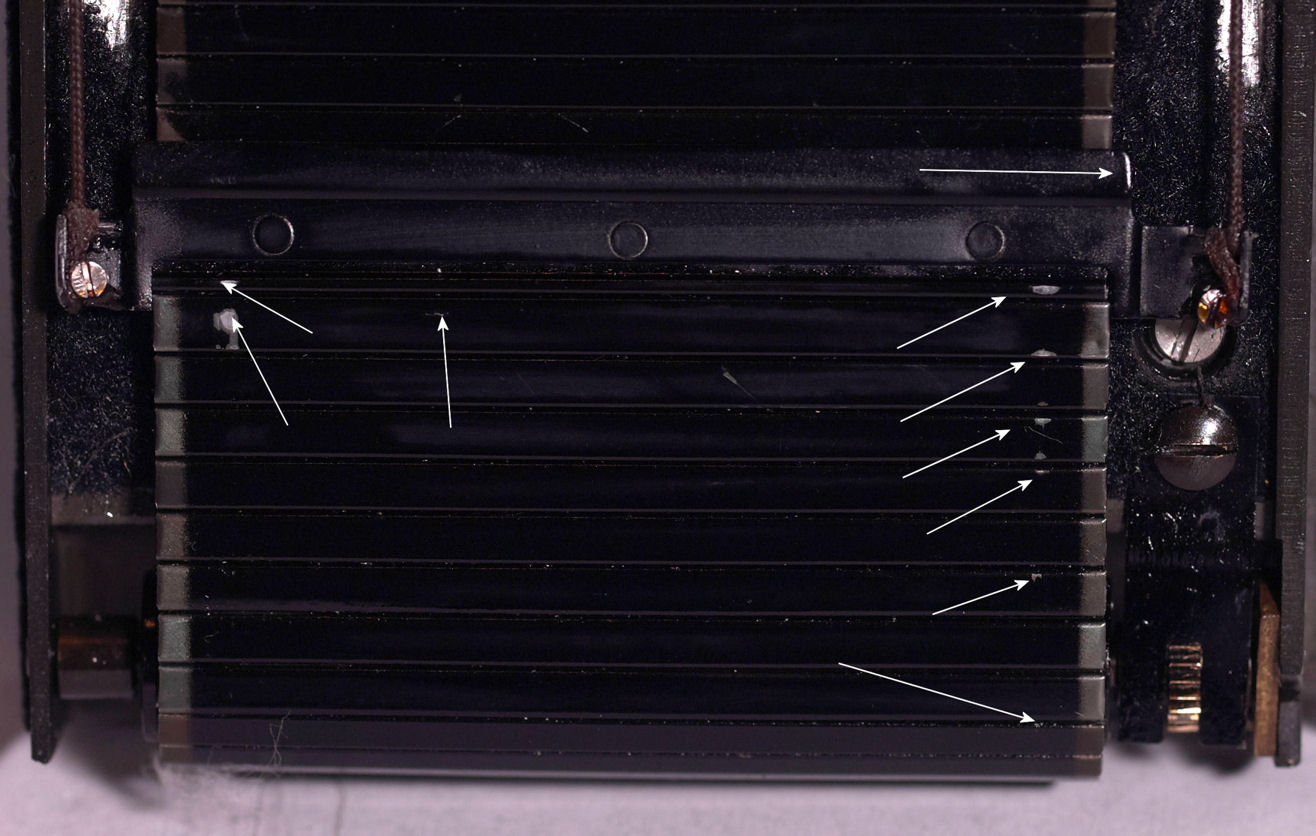

When a person buys a Contax the first assumption is based upon the assurance of the seller. In most cases the seller will describe the camera to be "working". This can mean anything. The problem is that the Contax was manufactued back before modern methods of quality control. This means it can have a great variety of problems resulting from improper part selection during the camera assembly process. It can also suffer from bad maintenance practices and the desperate attempts by others, over the years, to correct a serious factory defect. This is ilustrated by this picture of the lower shutter curtain of a Contax IIa received here for overhaul:

The white arrows show where the shutter curtain has rubbed against the inside of the camera body over the years. This particular shutter is an extreme case of this factory defect. Over the years workers over tightened the shutter springs and saturated the camera with cheap machine oil in their attempts to correct this shutter speed problems this rubbing causes. The over tightening of the shutter springs ruined them and the cheap machine oil ruined the camera leather. It was also necessary to lavish eight hours of filing work inside the camera body to remove enough metal so that the curtain would not rub when it descended. This was an expensive and labor intensive camera to repair. When you buy a Contax there is no way to know what is going on inside it or what has been done to it over its past fifty or more years of history.

External Condition:

There is a very serious reason why we go the extra mile to thoroughly clean, sanitize and polish the exterior of every camera that comes here for service. It is called basic sanitation. The exterior of your newly purchased, but used for about 50 years, Contax is filthy dirty beyond description. Bacteria, viruses, skin oil, just plain filth, and who knows what else has been layered on it year after year. Look at the milling of the speed control dial and you'll see a thick brown buildup. This covers the entire camera. It's just a uniform coating and so it's not as evident as it should be. My attitude is simply that it would be the absolute height of carelessness verging on a crime, to allow you to take such a thing, put it in your hands, and then raise it to your face or to allow you to handle it and then go have a nice sandwich.

Every camera that comes here is cleaned thoroughly inside and out to ensure that it is as clean as it was when it was new. I can tell you that I wash my hands thoroughly before starting the assembly of a Camera out of freshly cleaned parts. This is why all the exterior parts are ultrasonically cleaned. It is why all the leather is carefully dry cleaned and given a fresh outer surface.

A dirty camera is just loaded with allergens. It is more than likely that many people have suffered needless allergy and asthma attacks from a dirty camera. This can't happen with a camera that's been overhauled here.

Your continued good health is part of the reason it takes longer here. We don't do anything that is not necessary but we do things which are not obvious. Your fingers can tell the difference. They know what's clean and what's not.

Internal Condition:

The condition that counts the most is the internal condition. There are no spare parts available for the Contax IIa or IIIa other than replacement meter cells for the IIIa, and parts taken from other camera bodies. Each and every part in your camera is virtually irreplaceable. If your camera has not recently been completely disassembled, cleaned and lubricated it is very dirty with many parts grinding against each other dry. There are particles of old film and metal meshing with the gears, and accelerating the wear. Think of what your car engine would be like today if it was a 1956 model and you had driven it continuously since it was new, without adding any oil or having the original old oil changed. This is what the inside of your camera is like now. The following pictures demonstrate what the inside of a Contax IIa looks like even though the camera body appears cosmetically mint from the outside:

The first picture on the left is of the inside of the camera underneath the shutter speed control knob. The original grease became acid and has removed the nickel plating from the components inside the camera body. The middle picture is of the underside of the film speed reminder disk that is located on top of the rewind knob. You can see the grease became acid and has removed the chrome and nickel plating from the underside of the disk. The rightmost picture is of the front of the same disk showing that you cannot tell what the inside of the camera is like from looking at the outside.

The simple fact is that Zeiss designed its cameras to have periodic maintenance that included lubrication of the moving parts. The following two pictures illustrate this.

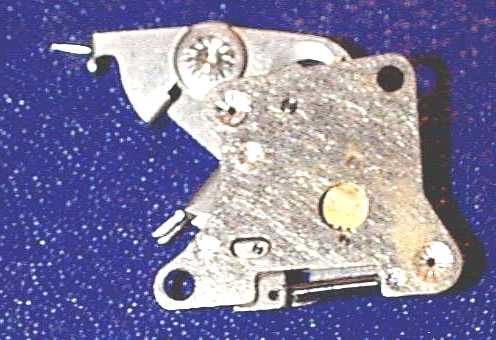

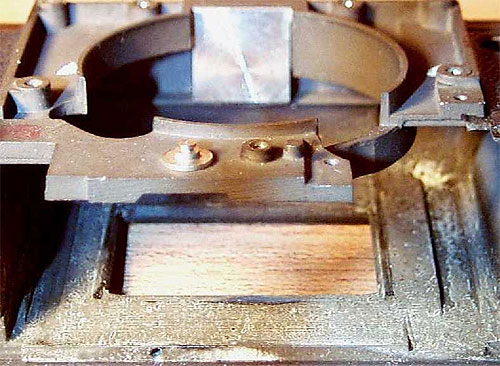

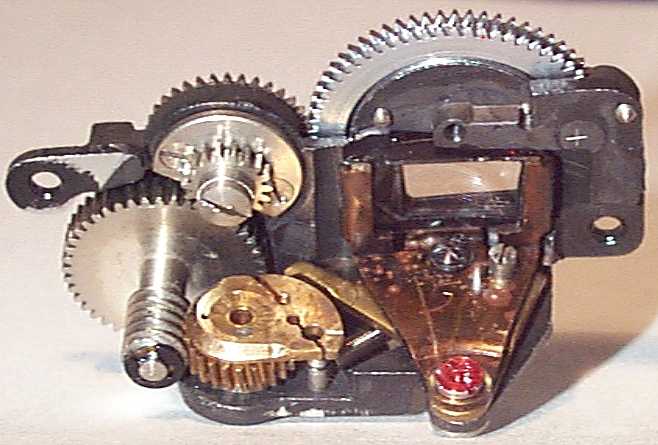

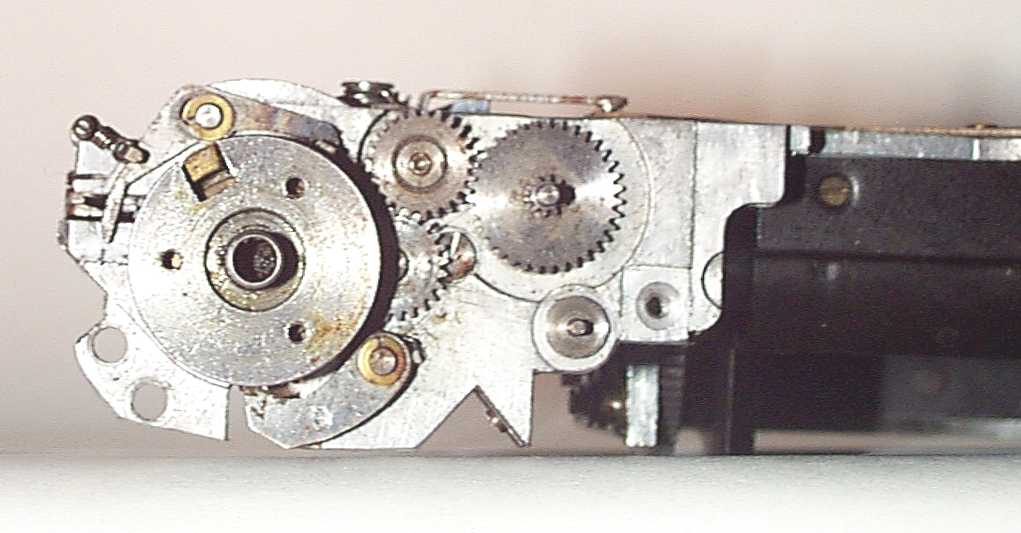

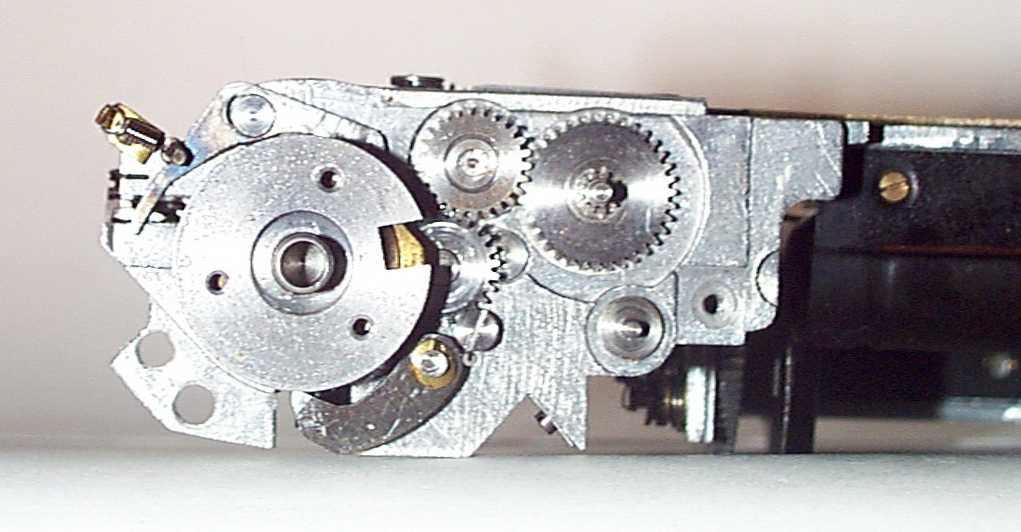

These pictures are of the middle speed escapement. This is the fourth and final version. Zeiss went through four changes to this very important part of the camera during the span of IIa/IIIa production. This is the timer that controls the shutter speeds between the speeds of 1 second through 1/100 second. It is shown in the left picture to be right side up and aligned as it normally is positioned when in the camera. On the right it is upside down. In the right picture at the bottom left you can see a small oval cutout that exposes a small bearing pivot. The only reason Zeiss would have made that cutout to expose that pivot is to allow that pivot to be lubricated with a very small drop of oil. So Zeiss designed the camera to be periodically lubricated. The question is, just how often? The answer is no longer than five years. The reason for this is that with the finest quality watch lubricating oil being applied to a freshly cleaned bearing, the oil will only stay in place for an absolute maximum of five years.

The question then arises, just how was the camera originally lubricated at the Zeiss factory when it was originally assembled. I have been able to examine enough Contax IIa and IIIa cameras that have been presented to me in unopened factory original condition to be able to answer this question conclusively. Zeiss lubricated its cameras very badly if at all. I have seen cameras that have had absolutely no oil or any signs of grease in them and appear to have never been lubricated ever. I have also seen cameras that were originally over lubricated, and I have seen cameras that were improperly lubricated. These problems are complicated by the fact that Zeiss seemingly did not think much about the kind of lubricants that would be used in the post war Contax cameras. I say this because I have observed that Zeiss used three types of grease in the Contax IIa and IIIa cameras.

Type 1 grease is a red colored grease that dries to a sticky hard transparent deposit. About 1 out of five cameras appear to have been lubricated with this grease. This grease appeared to have been useful for a fairly long time and was obviously appropriate to use in the camera.

Type 2 grease is a pale yellow colored grease that appears to be the same optical damping grease that was used in its lenses. It is usually virtually completely consumed by bacteria. About three out of five cameras appear to have been lubricated with this grease. It wouldn't last long in regular service.

Type 3 grease is molybdenum disulfide grease equivalent to that used in modern automobile wheel bearings and constant velocity joints. About one in five cameras appear to have been lubricated with this grease. It quickly decomposed to release its oil leaving a thick sticky semi hard deposit composed mostly of molybdenum disulfide powder and grease base. The use of this lubricant in a camera is so adverse to its proper operation I can only conclude from the fact it was used in a significant number of cameras that Zeiss did not think much about what lubricants it used in its cameras.

I have noticed a correspondence between the cosmetic condition and the type of grease found to have been used in it. Those cameras which were lubricated with type 3 grease are the best looking and those lubricated with type one grease are the ones that look most used. This makes sense because even when it was fresh a camera lubricated with type three grease was incapable of taking a good picture. The rare camera with no lubrication in it is always the best looking. All of these I have seen are true classic mint rating as museum quality.

The good news is that your old camera can still be restored to better than new operating condition at a very reasonable cost. It is possible to restore your camera to like new condition so that you can use it regularly without fear of damaging it further. The way to do this is to have it rebuilt by me. The following series of pictures are of a Contax IIIa during a complete overhaul. These are provided to help you understand just how precise and delicate the internal mechanisms of this very special camera are, and why regular maintenance is necessary to keep it operating at its best.

What is the Contax?:

The Contax camera is something you almost cannot find anywhere today. It is a hand made camera fabricated of hand made parts. Don't let the outside fool you. The outside chrome, glass and black paint look very modern and machine made. But inside it is all hand made and hand assembled. This means that each and every Contax is different. Each individual camera body is the work of the original assembler. This explains why there are many very beautiful Contax bodies available for sale today. They just pass from hand to hand with each owner having to find out for his or herself that the camera can't take a good picture.

I think the following picture demonstrates better than anything else just how "hand made" each Contax camera truly is.

The brass part on the right is the foundation of the wind knob and shutter speed control. On the far right of it you can clearly see that two holes have been drilled into it, but only one has a threaded screw hole underneath it. The extra hole was a mistake. The person whose responsibility it was to drill the mounting holes made a mistake and drilled the holes evenly spaced at 120 degrees from each other. This was incorrect so an additional hole was drilled in the right place. This was an appropriate decision. This part is very complex and was exceedingly difficult to make. Note also that the parts in this picture have been ultrasonically cleaned and look just like new. This is what the inside of your camera will look like when you get it back from me.

Each and every part of the Contax camera was made by hand. And this part is not an exception, it is an exemplar. Zeiss designed its cameras with parts that are subtly exceedingly complex and filled with subtle curves and high tolerance cutouts. I am a machinist and have tried to count just how many machining operations would be required to make this part and the number is very large. I know that if I needed to make one it would be much easier and cheaper just to buy a parts camera. Only the most highly skilled machinists had the skills to make Contax parts.

I think it is a good general rule about cameras that cameras that take good pictures get used. The get used, bumped, knocked, scraped and scratched. The chrome wears off the edges of the control knobs, the lens mounts get worn, and the paint gets knocked off the edges. On the other hand, a camera that is highly sought after, is expensive, and doesn't take good pictures sits on a shelf and looks nice. This explains why there are so many beautiful Contax cameras available today. They were not assembled properly.

I have opened and restored enough Contax cameras to know the assemblers were not given much training or instruction. I have seen Contaxes that were assembled with virtually no lubricant, and those which were saturated with grease. The problem is that assemblers were paid on a piece work basis. With piles of new parts, each with varying size tolerances, assembling a new camera so that all the parts mesh right is a back and forth affair. The camera goes together, then it comes apart over and over again until finally it is all together. I guess a good assembler could have put a good camera together in one day. But at the piece work rates Zeiss was paying in the 1950's, one camera a day would not pay the rent. So, it is my experience that two out of every three Contax cameras ever made didn't work right from the day they were made.

It can take a lot of work to make that beautiful Contax right. This is what I do.

The main fascination about the Contax IIa and IIIa cameras is the 1/1250 shutter speed. This is still a very fast speed today. The IIa and IIIa cameras were capable of providing this speed when new if they were put together properly and most were not. But even if the camera never worked right from the day it was made the potential for this kind of performance is still there. All that is needed is the proper cleaning, the proper honing, matching and adjustment of parts, the proper lubrication and the proper adjustments.

It has been my experience that it is usually possible to restore a camera so that all the speeds are accurate to well within 1/10 stop or better. In perhaps two out of three cameras, when I test the camera after assembly the speeds on the shutter speed control dial and the speeds indicated on the shutter speed tester match exactly; die. 1/1240 = 1/1250 all the way down to 1 second. This is astounding performance that is equal to that available from modern electronically controlled shutters. It is a remarkable testament to the excellence of the quality of the shutter design.

Contax Shutter Accuracy Today:

The Contax shutters we have today have traveled through at least 50 or so years of time. In this period, all of the lubricants used in the shutter have degraded and oxidized; becoming hard and sticky. It is this stickiness that degrades the ability of the shutter to perform at the higher speeds. In most cameras, this problem is called "shading". When the camera is held up to the light and the shutter is observed, one can clearly see that both shutter curtains meet before the bottom of the frame. This is caused by the lower shutter curtain descending more slowly than it should. It is the sticky old lubricant that retards it's speed.

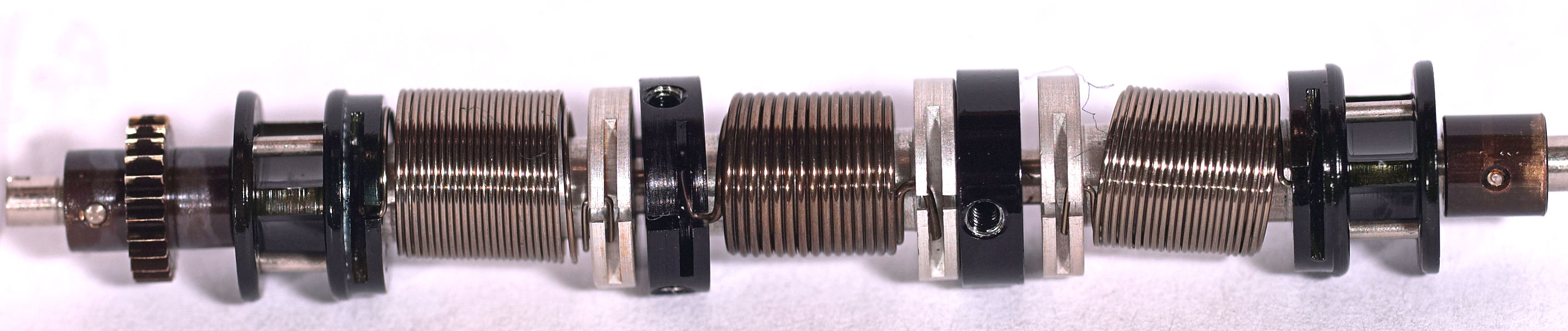

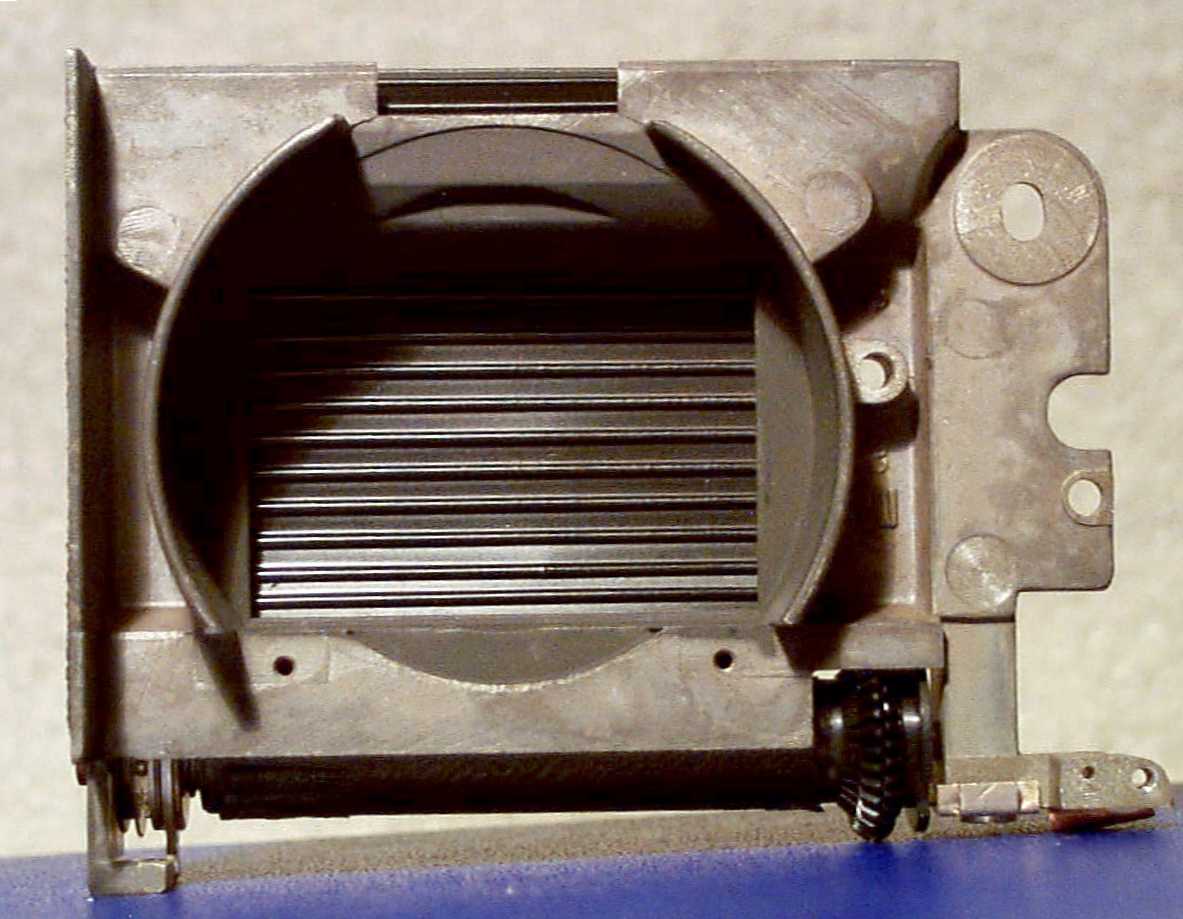

Another problem is that the parts have formed a layer of oxidation. This oxidation prevents the parts from attracting and holding the vital film of new oil that is necessary to restore proper operation. This is illustrated by the shutter curtain springs. This is a picture of the shutter springs in a Contax IIa/IIIa shutter. They were lubricated with grease when the camera was manufactured and by now this old grease has become hard and sticky. The old grease interferes with the movement of the springs lessening their speed and this affects the accuracy and long term reliability of the 1/1250 shutter speed. It also reduces shutter spring life because it forces the springs to be made much tighter to produce the same shutter speeds. It also affects shutter cord life because stronger spring tension means shorter cord life. During an overhaul these springs are hand cleaned with solvent to remove the old grease residue, then ultrasonically cleaned to remove oxidation so the springs will hold onto new lubricant. Then the assembly is lubricated with watch oil and finally the spring coils are painted with Swiss watchmakers spring grease. This is a lot of work but it is necessary because these springs are the heart of the shutter. In this picture the center spring coil is for the lower shutter curtain and the two side springs are for the two shutter tapes that pull down the upper curtain. These are very fine springs and are easily damaged by being over tightened. They can also loose strength by the camera being stored for a long time with the shutter cocked.

It is part of the normal camera aging process for the focusing wheel to become progressively harder to operate until finally it becomes painful to the finger. it is also possible that when the camera was originally assembled it was put together with a very stiff and rough focusing action.

There are six possible causes for hard, rough and noisy focusing action:

1. The first is dirt and environmental grime build up in the focusing helical threads in the lens mount.

2. The second is oxidation of the surface of the brass focusing helical threads in the lens mount assembly.

3. The third is the build up of fine dust in the helical threads.

4. The fourth is the drying of lubrication in the range finder assembly. A more infrequent cause is the drying out of lubricating grease improperly applied to the focusing helical threads by the original camera assembler or by a subsequent worker.

5. The fifth is that it is also possible for a very slight misalignment of the lens mount assembly when it is attached to the camera body to cause binding. This can also happen if the camera has been dropped. Frequently when a Contax has been dropped on the lens there will be no obvious damage to the lens mount assembly, but it will be distorted by the impact.

6. The Sixth is that it is possible for the surface finish and inner diameter of the stationary part of the focusing assembly to so match with the surface finish and inner diameter of the moving part of the focusing assembly so that they tend to catch against each other when rotation occurs. This possibility is the consequence of the use of an Acme type thread profile in the focusing assembly helical threads. Most, if not all, cameras ever made use the Acme type thread design in focusing assembly helical threads. The reason for this is that the Acme thread type design is very resistant to fouling by dirt and wear products. But it does require great precision in surface finish and component manufacture to avoid a thing called "juddering", which is what happens when moving parts catch and then move as they are rotated against each other. In some cameras the focusing assembly components were unfortunately mismatched with they were assembled.

The proper alignment of the focusing assembly to the camera body is highly critical to smooth and precise focusing action and feel. It can sometimes be extremely difficult to get this alignment just right because some cameras require a precision of one ten thousandth (0.0001"). The skirt of the focusing assembly mounts to the camera with five evenly spaced screws. Extremely thin spacing washers are placed beneath the skirt between it and the camera body at each screw. I have overhauled cameras that required no less than five sold hours of work to obtain a proper alignment of the focusing assembly to the body.

Fortunately is is possible in all cases to restore the focusing mechanism operating friction to better than when it was new. This is accomplished by careful ultrasonic cleaning of all the components, followed by the proper lubrication, and extreme care in the alignment of all the components when the camera is assembled. A distorted lens mount assembly can usually be restored to free rotation through the use of a great amount of elbow grease, fine diamond lapping compound and very thin spacing washers.

Zeiss was aware of the friction problem with the Contax focusing mechanism. I recently came across a Contax IIa with an experimental lens mount assembly in it. The focusing assembly had been made so the threads at the rear of the mount could be made to have a tighter fit than the threads at the front. This was done by the making of four equally spaced slits down the length of the helical. A groove was then cut around the rear circumference of the lens mount with a fine steel wire wrapped tightly in the groove to pull in the rear of the threaded section of the focusing assembly somewhat like a collet. The reason for this experiment was to obtain a looser fit at the front of the mechanism that would lower the friction combined with a tighter fit at a smaller portion at the back to increase the focusing precision lost by the looser thread fit. It didn't work from the factory. but I made it work through the use of much elbow grease and diamond lapping compound to lap the threads together to precisely the proper tolerance. It took about a day of very hard work to get it just right which explains why it was only experimental and was never implemented in regular production.

I can duplicate this in your camera if you would like to have absolutely spot on precision focusing action, but it will definitely not be cheap.

There is a very close connection between the tightness of fit of the focusing helical threads, the friction it takes to rotate the lens mount, and the degree of focusing precision that is possible. The looser the thread fit, the easier it is to operate the focusing wheel, the less precise the focusing. The average precision of focusing with a typical Contax is about four inches due to focusing helical thread tolerance.

It is part of the normal camera servicing procedure to use very fine diamond compound to polish the helical threads. The result is better than new focusing action. The extreme fineness of the compound I use does not increase the degree of focusing imprecision that is inherent in the mechanism.

No camera leaves here until its focusing action has the same feel as every other camera that leaves here and this is what I expect would be the standard of perfection at the Zeiss factory when the camera was originally manufactured.

What is the Cause of Focusing Helical Clearance or Looseness?

I frequently am asked why the focusing action on a pre-war Contax II or III is much smoother than that of a post war IIa or IIIa camera. The reason this is so is both simple and complex.

It is a fundamental law of camera design that long camera life comes from mating brass moving parts against steel parts wherever possible. Brass against steel wears better than brass against brass or steel against steel.

In the prewar Contax II and III cameras the focus system gear train from the range finder wheel to the rotating focusing helical is brass, steel, brass. And this works very well because the gears are all mounted to the camera body and can be mounted with great precision and firmness. This means that everything can be made so that wear to the moving part of the focusing helical is held to an absolute minimum. So the focusing action is very precise, tight and smooth.

In the postwar Contax IIa and IIIa cameras the focus system gear train is all contained in the range finder module. The range finder module is movable and must be adjusted when the camera is assembled. It is necessary to remove the range finder module to disassemble the camera for maintenance. The result is that it cannot be adjusted to the same degree of precision as the mechanism in the pre war cameras could. This inability to precisely adjust the gearing resulted in the possibility of accelerated wear to the gear teeth that are cut on the moving part of the focusing helical. Zeiss solved this problem by applying a "hard" chrome plate to the gear cuts in the rotating part of the focusing helical. The thick layer of chrome protects the underlying brass from accelerated wear caused by misalignment of the range finder module and its steel gear that rotates the focusing helical..

"Hard" is a technical term applied to chrome plating. It refers to chrome that is plated to a thickness where it is not transparent as it is in normal "decorative" chrome plating. Hard chrome plating is very expensive and very difficult to apply with precision to a complex surface like a focusing helical. It would not have been specified by Zeiss unless it was absolutely necessary. But hard chrome plating introduces a big friction problem.

When chrome is plated thickly (hard) it cracks and develops a microscopically rough surface. So hard chrome is not smooth like decorative chrome. This surface roughness increased the friction of the mating parts of the focusing helical and the only way to decrease the friction and keep the chrome plating was to increase the tolerance of the fit. Rather than do away with the chrome Zeiss decided to increase the clearance between the moving and stationary parts of the focusing helical which made them looser. But even though the clearance was increased the roughness of the chrome plated surface remains.

The good thing about hard chrome is that the microscopic cracks allow it to hold lubricant very well. So parts in valuable machines that must have a long service life, such as locomotives and nuclear submarine parts, are hard chrome plated. The problem with using most grease type lubricants on the Zeiss Contax focusing helical is that they do not decrease the operating friction because the surface area is so large. Most, if not all, lubricants provided by suppliers for photographic use actually make focusing harder when they are used in the Contax II and and IIIa focusing helicals. Oil cannot be used because it will not stay on the helicals and will quickly migrate into the rangefinder system and fog the viewfinder.

Fortunately, there is a solution to this problem. I have recently found a French watch grease that is so finely made and so light it will actually decrease the operating friction of the focusing helical. This grease provides a focusing action that is very smooth and fine, without excessive looseness, and very close to the feel of the pre war Contaxes.

It is a very common defect for a Contax IIa or IIIa camera to have a problem with the rangefinder where the viewfinder and rangefinder images have a vertical misalignment. In some cases this misalignment is so great it is impossible to focus the camera. This problem has been another reason for there being so many beautiful unused Contaxes for sale.

Zeiss used two different cements to hold the rangefinder module lenses in their frames. The first cement they used is a water soluble glue. This glue appears to me to be hide glue. It deteriorates over time and becomes very brittle. It cracks and crumbles into small pieces. This process leaves the lenses loose in their frames and the shifting of the lenses causes the image vertical offset. I see many cameras where modern plastic cement has been applied to this glue in an attempt to hold it together. This technique works for only a limited time.

The second cement is a black epoxy paste. This was used in later production cameras. This cement is very hard and permanent and holds the lenses tightly in place. Rangefinders in which Zeiss used this cement typically do not have image offset problems and will never develop them.

When a camera is sent here that has the water soluble glue I change it out with modern epoxy. This guarantees the rangefinder image alignment will be permanently correct.

There can be other causes for this problem. Sometimes when the lens cement problem is corrected one of these other ones becomes evident. You can see in the following picture a back view of the rangefinder module that shows the moving lens on the right. The misalignment of the viewfinder image to the rangefinder image can have three possible causes. The lenses can have been improperly ground, one or both lenses can have been cemented into their frame(s) upside down, or one or both lenses can be vertically and/or horizontally misplaced in their frames. It can sometimes be very difficult to diagnose the actual problem and then repair it. The alignment must be extremely precise and final adjustment of the lenses can sometimes take a week of cementing, moving a lens slightly, then recementing it. Compounding this is the small size and fragility of the rangefinder module parts.

The range finder prism is a cemented optical assembly. The cemented prism is split at an angle midway between the viewfinder lens and the viewfinder window. One side of the prism was coated with a very thin layer of gold or platinum before the two halves were cemented together with balsam optical cement. It is this reflecting layer of precious metal that half reflects and allows light to transmit through it. If you camera has a gold mirror in its prism, the viewfinder view appears slightly greenish, and the range finder window appears gold. Light transmitted through gold appears green. If the prism in your camera was coated with platinum both the range finder and the viewfinder images have the same normal color.

The following picture shows two prisms for a Contax IIa/IIIa camera. One is complete, and the other has been separated to show the way the prism is put together.

The gold or platinum was deposited onto the surface of the glass through a process called "sputtering". This process deposits a very thin film of metal on a surface that is in a vacuum using high voltage electricity. It is virtually impossible to form the same quality of metal film by methods other than sputtering. Commercial sources are available for this service, but the price is prohibitive. The last quotation I was able to obtain was $450.00 per piece. Clearly, it is cheaper to purchase a parts body merely to obtain the prism from it.

If you have a platinum mirror in your prism, and you have compared the image in your camera to a camera that has a gold mirror in it you may be under the impression there is something wrong with your prism. The key measure of your prism is can you focus easily with it? If you can, and the viewfinder image is not light green, you have a platinum prism and there is nothing wrong with it. The contrast between the range finder and viewfinder images in a platinum prism is much less than exists in a gold coated mirror prism.

The best way to check a prism is to look into it with a magnifier from the front. A good prism will be clean and clear. One that is not good will likely show clearly evident mold growth, mottling and discoloration.

At the time of the writing of this I am experimenting with less expensive methods of restoring the Contax prism. If you have a bad prism and do not want to purchase a parts camera to get a good one, keep checking back. The day I have success this section will be updated.

There are a number of defects that can exist in the little rectangular rangefinder image in the viewfinder. They usually show up as black or blocked out portions of the rectangle. These defects can have a great number of causes, all of which will have the same optical result. Among these are chipping or damage to the prism end behind the rangefinder window, damage or chipping to the lenses in the rangefinder assembly, a broken and re cemented prism, paint defects, dirt, or a sticky film chip stuck on the prism end. It isn't possible to know the cause for sure without disassembling the camera.

Zeiss glued the eyepiece bezel into the top plate using a powerful thread locking adhesive. This makes it extremely difficult to remove under the best of conditions. Most workers don't know this and when they try to remove the eyepiece the attempt is made using a pair of pliers. The result is that the jewel like quality of the bezel knurling usually gets gouged and ruined, the chrome gets scraped off in places, and the finely finished annular section around the eyepiece lens picks up a number of very deep and ugly scratches. It's usually a big mess and nothing makes the value of an otherwise beautiful Contax go into free fall harder than a ruined eyepiece bezel.

Luckily a lot can be done to correct the situation. It is possible, using the proper special custom manufactured tools to remove the eyepiece assembly without damaging it further or damaging the top plate paint. Once it is out it is possible to skim cut and then apply new beaded knurling to the outer rim. The inner annulus can also be skim cut to remove scratches and gouges and then refinished to glistening perfection. All this can be followed by Rhodium plating followed by deep coat of diamond hard clear gunsmiths baking lacquer. The result will be like new with only a slight metal tone difference between the original chrome and the new Rhodium plating.

If your problem is a camera that is truly mint otherwise, and nothing but original perfection will do, bright chrome plating is also available at additional cost.

It is possible for the rangefinder to be the cause of fuzzy pictures, but not usually. My experience has been that the main cause for out of focus pictures is a misalignment of the lens element assembly within its body. The lens is made so that an adjustment for proper focus is relatively easy and straightforward if one has the proper tools and instruments to do it.

It is very easy to check the rangefinder. Check the split image against the engraving on the lens mount on the camera body. If the split image lines up properly on a far object when the lens mount is set at infinity; and then then also at one very nearby the rangefinder is operating properly and the lens is the problem.

The Contax IIa and IIIa cameras must be completely disassembled in order for the shutter to be completely serviced. This is the way Zeiss designed the camera. It is exacting and precise work. In the rest of this document you will see many pictures of the camera and shutter being disassembled for a servicing. What is in these pictures is not special. Each and every camera serviced by me is given the complete treatment it needs so that it will work right each and every time for many years.

The Contax IIa and IIIa shutter has several mechanisms that require adjustment. Unlike all previous designs, the more modern IIa and IIIa shutter design incorporates the ability to adjust the high, medium and low speeds separately. This provides for the greatest possible linear range. However, wear and abuse may limit the ability of a shutter to be adjusted to the original factory specifications.

The original shutter tapes were made to explicit design criteria for

Zeiss. The tapes used during a modern rebuild are the silk

tapes. They have a specific weave and dimensions. These

are not available today. Substitute material is used by many people.

Many people use rayon ribbon obtained from craft supply houses. There

are three problems with this tape. The size is usually incorrect,

the material stretches under tension, and it is not durable. Only

silk provides the required durability and resistance to stretching under

tension. Only the required dimensions result in the proper friction

when the tape slides through its slots in the upper shutter curtain.

I use new silk shutter tapes made to the same specifications as the original.

I am sorry to have to say I cannot sell any. The supply is sufficient

only for my needs.

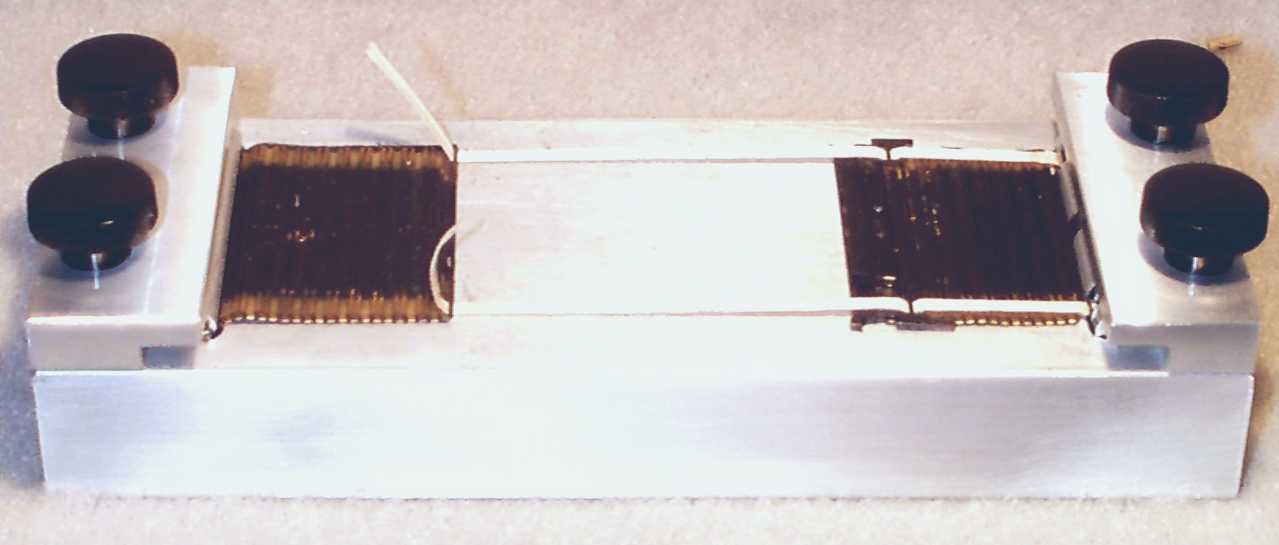

The following picture is of a special tool used

to set the shutter tape length:

This fixture ensures that the shutter curtain edges will be absolutely parallel during exposure. It also demonstrates that to repair Contax cameras, one must be able to afford, or to make all of the special tools required to ensure the job is done right the first time. Tool design is a separate specialty and requires some time since none are available to copy.

Color Dial Model Shutter Reluctance to Release:

The shutter release mechanism of the Color Dial Model IIa and IIIa cameras is much more complex than the one in the Black Dial model cameras. The Color Dial shutter release mechanism contains two electrical interlock switches that are part of the flash synchronization system. It also contains an additional shutter release interlock. All this additional complexity makes the mechanism more sensitive to the build up of wear products, roughness caused by surface oxidation, and gumming caused by the hardening of old grease. A Contax IIa or IIIa Color Dial model with a shutter that will not release reliably is one that needs a complete overhaul. This is the cure.

I recently overhauled a Contax IIIa color dial camera that had previously been sent to a very large and reputable camera repair shop. The owner had paid $200.00 for his camera to be serviced there. He sent his camera for servicing because the shutter was not releasing reliably. When he got his camera back after a three month wait nothing had changed. The camera shutter was still not releasing reliably. So he returned it under the guarantee (three months) and waited another three months and got it back in the same condition. The shutter would still not release reliably. Finally he sent it to me. When I disassembled the camera I found that the only thing that had been done to the camera for his $200.00 was that a single 0.005" thick washer had been placed underneath the shutter release button. This is about a ten minute job max. When the owner got his camera back from me two weeks later he took it on his lifetime trip to Paris and reported perfect operation and wonderful results.

When you get your camera back from me it will have

been completely restored to it's highest possible potential and it will

be reliable. It will have been completely overhauled. You will

get more than $205.00 worth of work for your money.

Shutter capping is a phenomena of the older Contax II and III cameras. The shutter curtains on the IIa and IIIa cameras do not latch together or cap. A built-in bias between the upper and lower shutter springs holds the curtains together as they are raised when the camera is wound.

In the very first production models of the Contax IIa and IIIa model cameras there was a problem observed with some cameras that the lower part of the film frame would not be exposed. It was discovered that the problem was caused by the lower shutter curtain hitting the inside of the camera body and bouncing back up a short distance. The solution to this problem was to cut a recess in the bottom of the camera case so that the parts of the lower shutter curtain that hit the case would have some clearance.

I have seen only one Contax IIa that had a hand modified case to account for shutter bounce. It didn't take Zeiss long to make a change to the camera body casting so that the necessary recesses were built in. I'm also sure that as cameras with shutter bounce problems came into the repair system their old bodies were replaced with newer once so that by today there are probably no cameras having this problem.

In more modern times the phenomena where the upper part of the film frame is unexposed has also been attributed to shutter bounce, but the correct name for this is "blanking". The cause of this problem is simply that the upper shutter curtain is traveling faster than the lower curtain and they meet before the lower curtain reaches the bottom. The cause of this speed mismatch is usually twofold. The first is general camera fouling caused by deterioration of the original lubricating grease and the second is excessive wear to the very complex, delicate and subtle shutter action control mechanisms. The only real remedy is a camera overhaul.

I have seen a great number of cameras that have this problem. Among these are a great number of cameras that were sent to other "experts" to have the problem corrected. In every case where the camera is sent to me after being repaired by another an entirely incorrect and highly damaging method has been used in an attempt to correct the problem. This method involves bending the moving arm that whose position is set by rotation of the film speed dial. The effect of bending this arm is actually to set the speeds lower than the dial indicates. For example: Suppose a camera is blanking at 1/500 and 1/1250, but it is not blanking at 1/250. The appearance that the problem is solved can be achieved by bending the speed control arm so that when the speed control dial is set at 1/1250 the camera internals are actually set at 1/250.

The problem with this approach is that it does nothing to correct the actual cause of the problem, it is deceptive, and the control arm has an extremely precise and subtle shape. It is extraordinarily difficult to get it back into the correct shape so that when the real cause of the problem has been corrected the arm will perform properly. This is a damaging technique that should never be used.

My shutter looks bent, what causes this?:

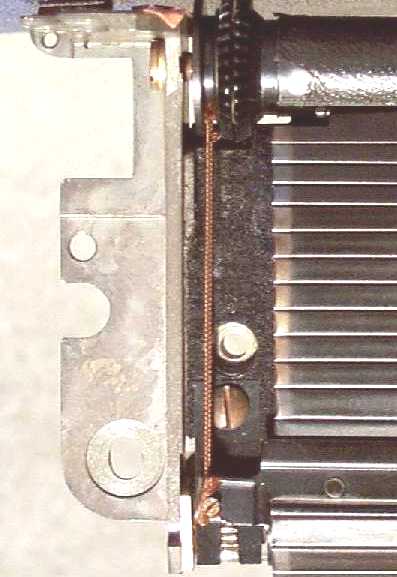

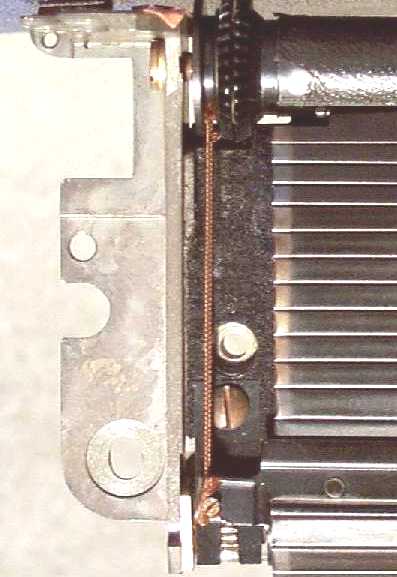

The shutter curtains do not cap and lock together as the shutter curtains in older Contax camera designs did. The position of the upper shutter curtain lip is held precisely in alignment with the lower shutter curtain lip by two cords on either side. The following picture shows the cord on the left side of the shutter.

The position of the shutter as shown in the picture is as it would be in the camera if you were looking at it through the lens mount.

The cords must be very precisely adjusted. If the cords are even a fraction of an inch longer than they should be, the upper shutter curtain lip will hang down too far into the camera body where the body cavity becomes smaller. This forces the shutter lip to bow outward making it look like it is bent. The shutter curtain stays bowed when it is cocked. So the shutter curtain appears to be bent. Correction of this problem is very tricky and difficult. The cord material cannot be replaced since there are no spare parts, and there is no satisfactory substitute. Removing it from where it has been glued into place, and then resetting it on both sides takes extreme care.

Right above the cord you can see two bevel gears. These gears operate to pull both shutter curtains up simultaneously, and allow the descent of each curtain to be controlled independently. This simultaneous lifting is what keeps the lips from separating and exposing the film while the shutter is being cocked. The shutter tape is not visible as it is covered by the edge of the shutter curtain.

Shutter Cocking and Film Advance:

The winding knob simultaneously winds the film advance and cocks the shutter. The design of the IIa and IIIa shutter is very different from that of previous cameras.

The shutter release mechanism for the Black Dial model is much simpler than is the one in the Color Dial model so the Color Dial model is more susceptible to jamming. Jamming is caused because the shutter is cocked, but cannot be released, so the wind mechanism is locked. There is no way to clear a jam from outside the camera. A jammed camera is a camera that needs a complete service.

Never ever force the winding knob. Don't even think about it. All this will do is to break a great many expensive parts.

Never shock the camera. Don't even think about it. Many rangefinder prisms have been split by cameras being hit hard in frustration. A broken prism can only be replaced by purchasing a parts camera with a good prism.

Most people use their cameras at 1/1250 very seldom if at all. And most people use the self timer very seldom if at all. So most people never come to experience a blank frame when the camera is set at 1/1250 and the self timer is used. When the self timer is set and the shutter release is depressed the shutter is released and moves a minute distance. The lower shutter curtain moves a slight amount and is then held by the self timer catch. When the timer runs to its completion the self timer catch is retracted and the lower shutter curtain is released. So, the self timer catch takes the place of the normal shutter release mechanism and the shutter components are slightly out of full cock alignment when the shutter is released by the self timer. The balance and alignment of the shutter components must be in very delicate and precise alignment at the point of release for the shutter to perform properly at 1/1250 speed. So it is normal for the frame to be blank if the camera is used with the self timer when the speed dial is set at 1/1250 if the camera has not been serviced in a long time or if was last give a typical "CLA" type service.

It is possible that you may take your camera and test it to find out if this behavior is happening with your camera. It is also possible that when you get your film back you will find the frame is exposed. If this is the case you have not proven your camera will work properly when the self timer is used to release the shutter at 1/1250. What you have demonstrated is that your shutter is considerably slower than 1/1250 when it is set at 1/1250. The reason for this is that it is a very common practice by most workers to deliberately reset the camera shutter speeds low to avoid shutter bounce. This is done to avoid the hard and complex work of completely disassembling the camera and cleaning and lubricating it and then properly adjusting it so that when the shutter speed dial is set at 1/1250 it actually exposes film at this speed. My experience with most cameras that I receive that have been "CLA' d" by others is that when the speed dial is set at 1/1250 the shutter is actually exposing at about 1/300.

Another thing to consider is that you cannot evaluate the behavior of a shutter using color negative film. The reason for this is that modern color negative film contains two separate layers having different speeds. An ISO 800 film will have an ISO 800 layer and also an ISO 200 layer. The reason manufacturers are doing this is to increase the yield of satisfactory pictures from film exposed by amateurs in simple cameras. Keep in mind that film makers make most of their profit from the film processing and not from the sale of film and cameras. With film having two layers with widely differing speeds it is more likely that the simple amateur camera will capture a printable image. This greatly increases the profit for the film manufacturer and also reinforces customer loyalty to a particular film brand. So if color negative film is used to test a Contax whose shutter is widely off its true speeds, it isn't possible to determine this from prints. They will all look good because the film is made to make a printable negative regardless of the shutter speed, and the processor is very expert in making good prints from bad negatives. If you want to know what your shutter is really doing you must use a narrow exposure latitude single layer film whose results cannot be manipulated during the print making process to evaluate your shutter. Kodachrome 25 is a good film for this purpose.

Setting a Contax IIa and IIIa shutter is much different procedure than is used for other focal plane shutter cameras. Leica type cameras have individual adjustments for the first and second shutter curtain springs. In the Contax both springs are attached to the same shaft and so there's one adjustment for both springs. The Contax IIa and IIIa shutter has six separate separate adjustment points. Four of these affect the speeds of 1/250 to 1/1250 and they interact with each other. The other two affect speeds of 1sec. to 1/100 sec. and B.

The proper procedure after a camera rebuild is to adjust 1/1250. Due to the fact this speed is adjusted by the manipulation of four interacting adjustment points it can be a complex procedure. It's time consuming because it's also necessary to wait some hours after each adjustment to ensure the adjustment has settled in before measuring the resulting shutter speed and moving on if necessary. In some cameras it can take as long as a week to get the fastest and most reliable high speed adjustment settings set properly. Each camera is different and requires its own special treatment to find out the exact settings necessary.

A big complicating factor in setting shutter speeds is that it is necessary to obtain the settings that result in the least necessary shutter spring tension. A lower tension results in increased shutter tape life, less inclination for the shutter springs to take a set, and it greatly increases the life of the shutter cords.

The Contax IIa/IIIa shutter has a set of two very small diameter cords that set the bottom stop for the lower shutter curtain. When the shutter is released the lower curtain drops and is stopped by these cords which unroll from spools. There is no modern replacement cord that works properly and so it is extremely important to set the shutter so that the tension on the shutter springs is as low as possible. In some cameras it takes a lot of time and adjusting to find out the optimum set of adjustments that result in the most accurate speed with the lowest possible spring tension settings.

The Contax IIa/IIIa shutter tape tends to fray if the shutter spring tension is set too high. Fraying causes it to develop fuzzy surface due to broken threads. When the upper curtain descends, the upper lip slides down on top of the shutter tape. If the tape is frayed the high shutter speeds cannot be set properly due to the increased friction between the tape and the curtain lip. This is another important reason to take great patience and care in the setting of the shutter to obtain the lowest possible shutter spring tension.

The Contax IIa/IIIa shutter has a problem in that it is very easy to mask underlying inner shutter mechanism friction problems by simply cranking up the shutter curtain tension. Many of the cameras I see that come here are suffering from shutter problems that have been caused by being used for too long with shutter springs that have been set at a tremendously excessive shutter spring tension.

It is possible to access the shutter spring tension adjustment without disassembling the camera. I have seen enough previously "serviced" cameras here to know that most servicing's or "CLA's" consist merely of ratcheting up the shutter spring tension to the point where the shutter appears to work properly to the eye, and the application of windex and shoe polish to the camera exterior.

What About a $119.99 CLA?

This is the picture of the inside of a Contax IIa camera body shell before it was cleaned. It is in the condition it was in when it was first opened. The white deposit visible coating the inside surfaces and which forms a small ball in the upper right hand corner is mold. It is normal for a Contax body shell to be coated with mold or bacteria.

A regular CLA does not include a thorough cleaning of the inside of the Contax body shell. This body shell is dangerous to your health and it will also infect any lenses that are mounted on it. If you are allergic to mold a camera such as this could wind up costing you a trip to the hospital. This is why every camera that comes here is thoroughly and completely cleaned inside and out.

When people write to me about a recently purchased Contax IIa the main problems of concern are focusing adjustment difficulty, viewfinder/rangefinder haziness, and high speed shutter curtain shading. Unfortunately, it is relatively easy, in a quick, temporary and superficial way to address these items and do nothing else about the camera with relative ease and cheapness. This is what you get for $119.95. The result is a camera which for the most part is still grinding itself to pieces. It is also possible to permanently damage the camera severely with the normally applied cheap and quick solution to shutter shading.

- Focusing stiffness can be temporarily cured by the application of a couple of drops of oil to the focusing helical by access through the focal plane when the shutter is opened on Time Exposure.

- The rangefinder haziness can easily be "cured" by the use of a couple of cotton swabs and removal of the top of the camera.

- Shutter shading can be "cured" temporarily by increasing

the shutter spring tension. While this has the effect of curing shading,

it also decreases the high speeds of 1/1250 to actually be 1/300..

It also, in many cases, results in shutter springs that are permanently

damaged beyond repair. If a Contax shutter spring is tightened too

much it will fold in on itself and will become permanently bent.

It is only possible to know if the shutter springs have been so damaged

when the camera has been properly disassembled. This kind of damage

is very easy to accomplish.

I have put this page together to demonstrate the various steps in the complete winterization overhaul service of a Contax IIa range finder 35 mm camera. This is a work in progress and so as my overhaul of the current camera progresses I hope to add more pictures to fill out the entire story. The following pictures illustrate parts of the assembly process and pictures of critical cleaning and polishing steps. I am hopeful this first offering will help you understand the workings of this very unusual, complex and high precision mechanical marvel.

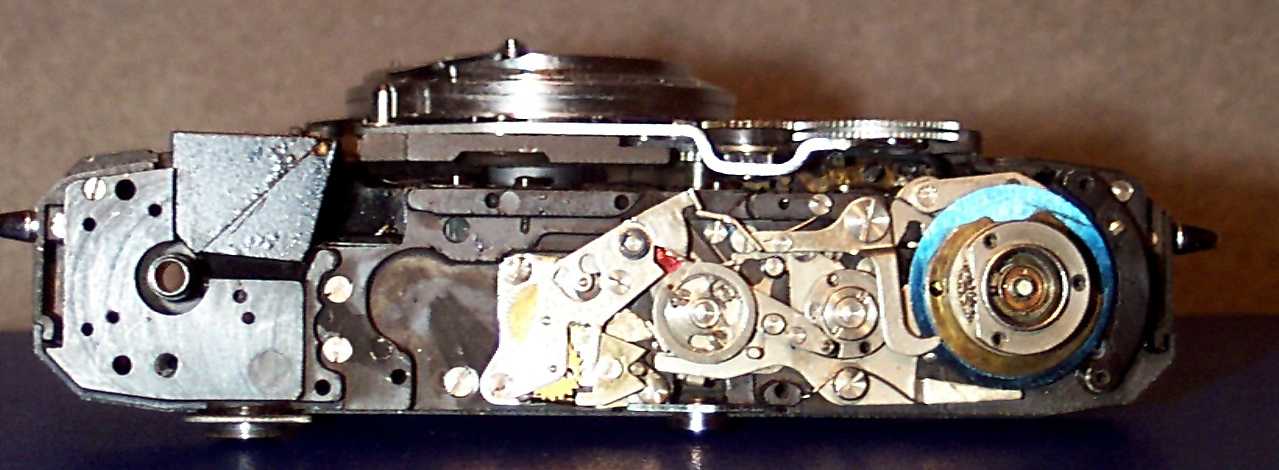

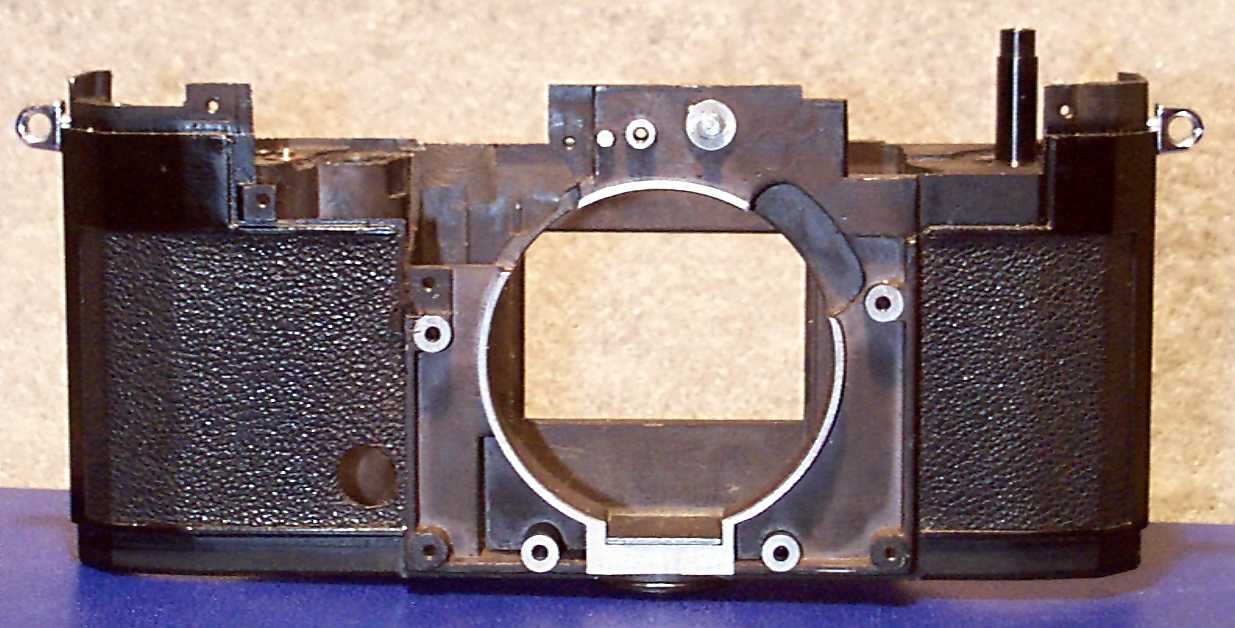

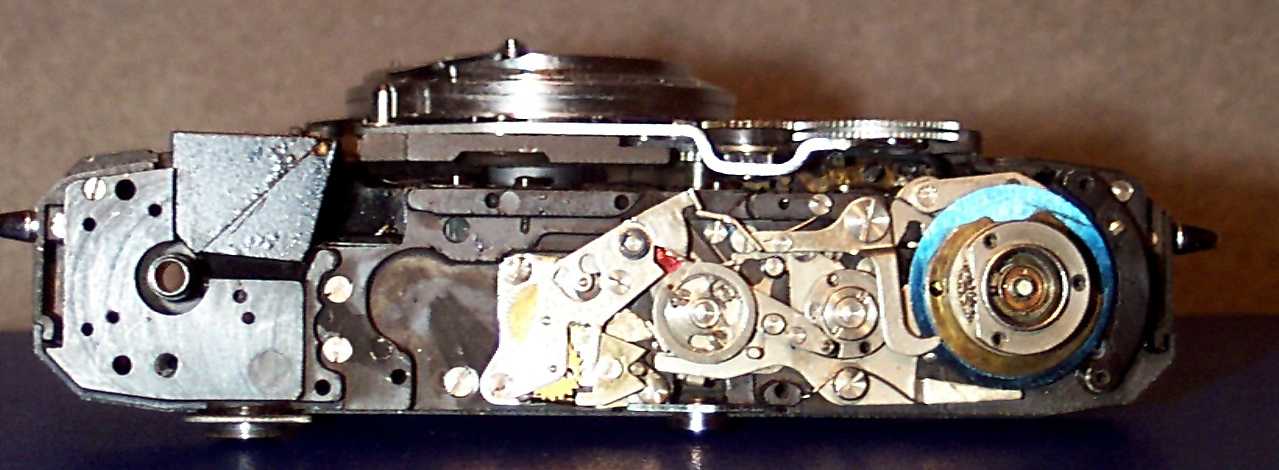

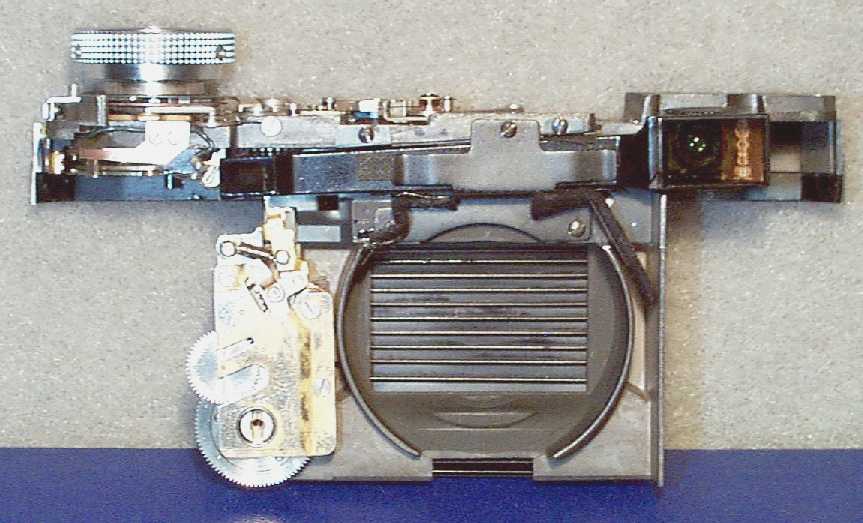

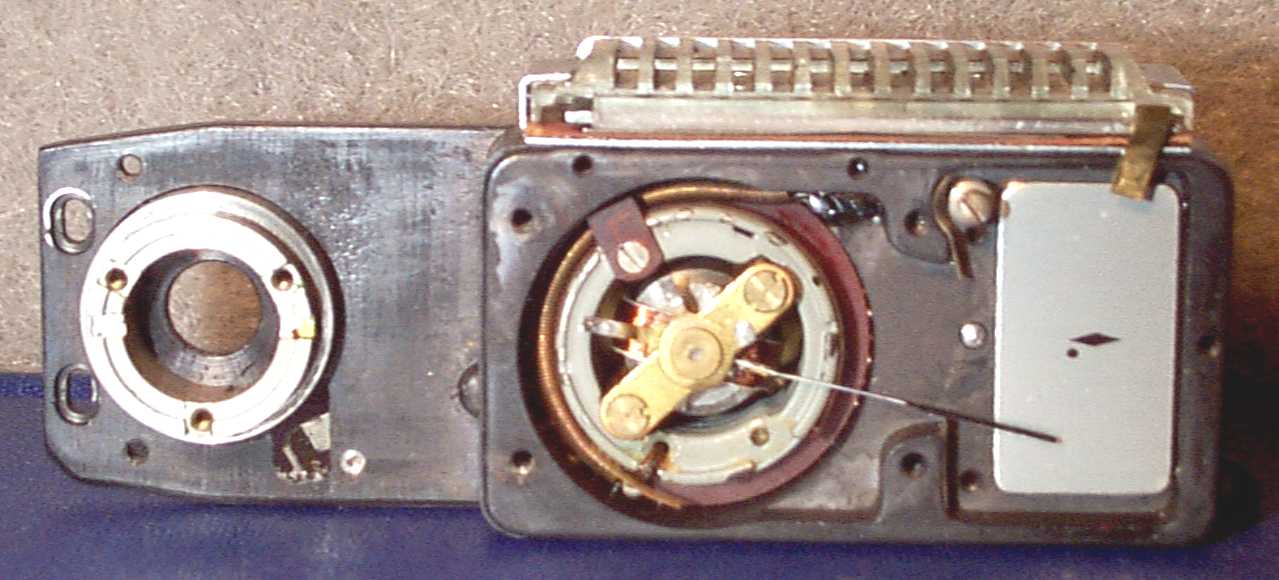

The first picture is of the camera when the top and bottom trim plates have been removed:

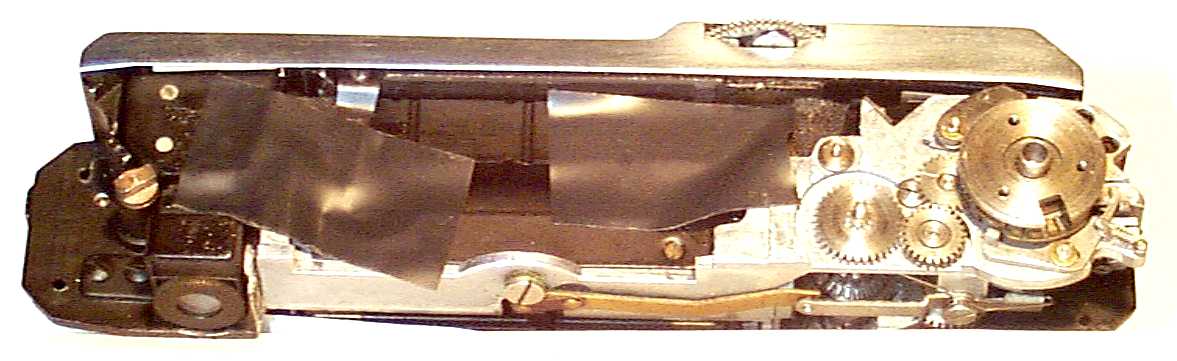

The next picture is of the body shell with the shutter mechanism module removed:

.

Notice that all components have been removed from the empty shell. This is part of a complete overhaul. All parts must be carefully examined, cleaned and lubricated. This is the only way to take the camera back to the day it was made and get that original factory performance and reliability.

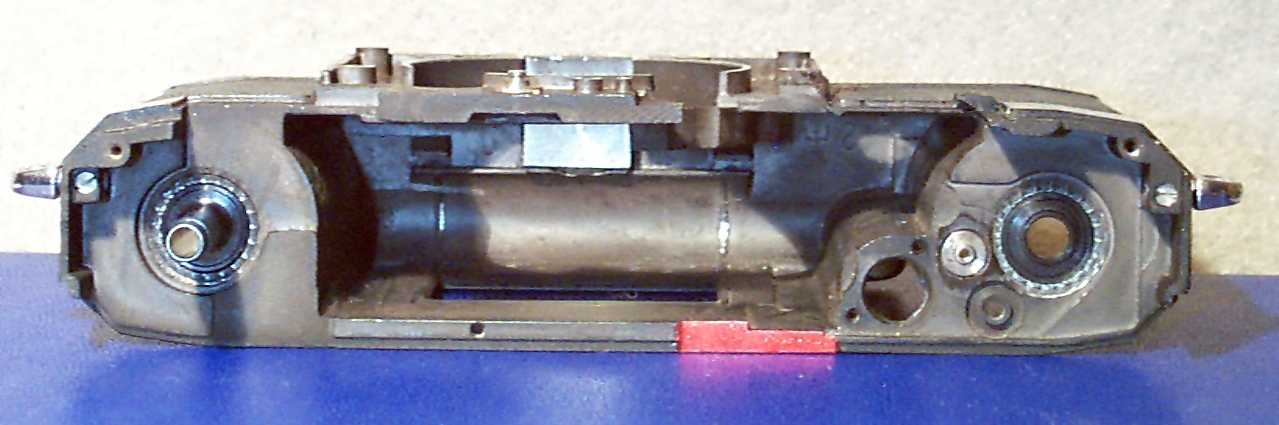

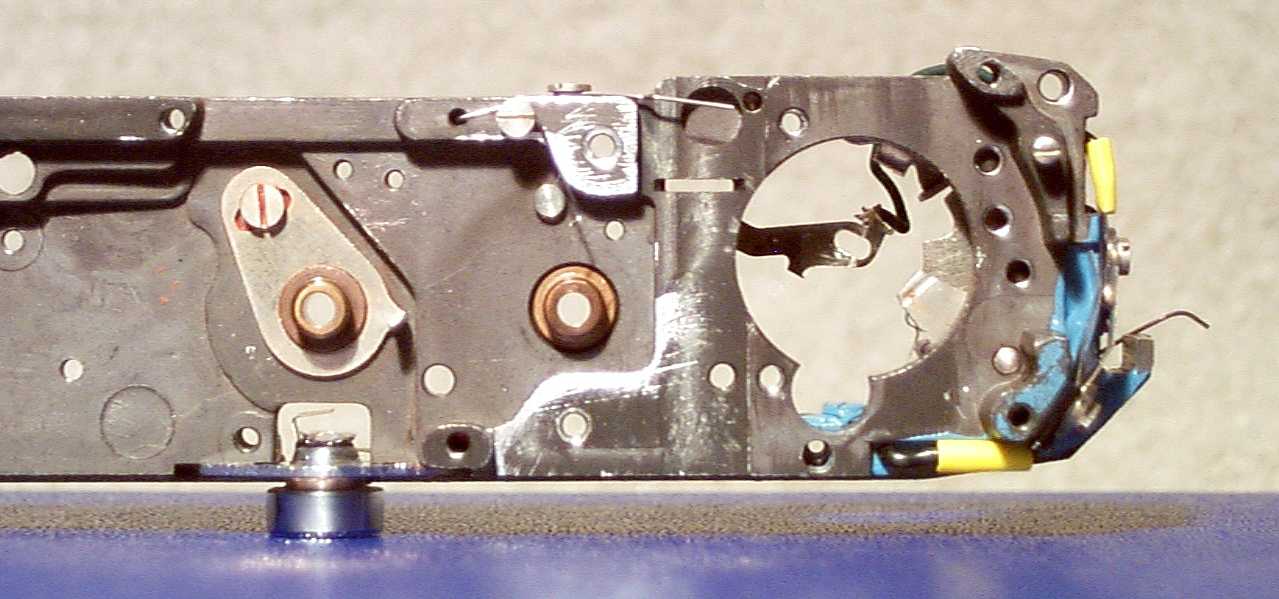

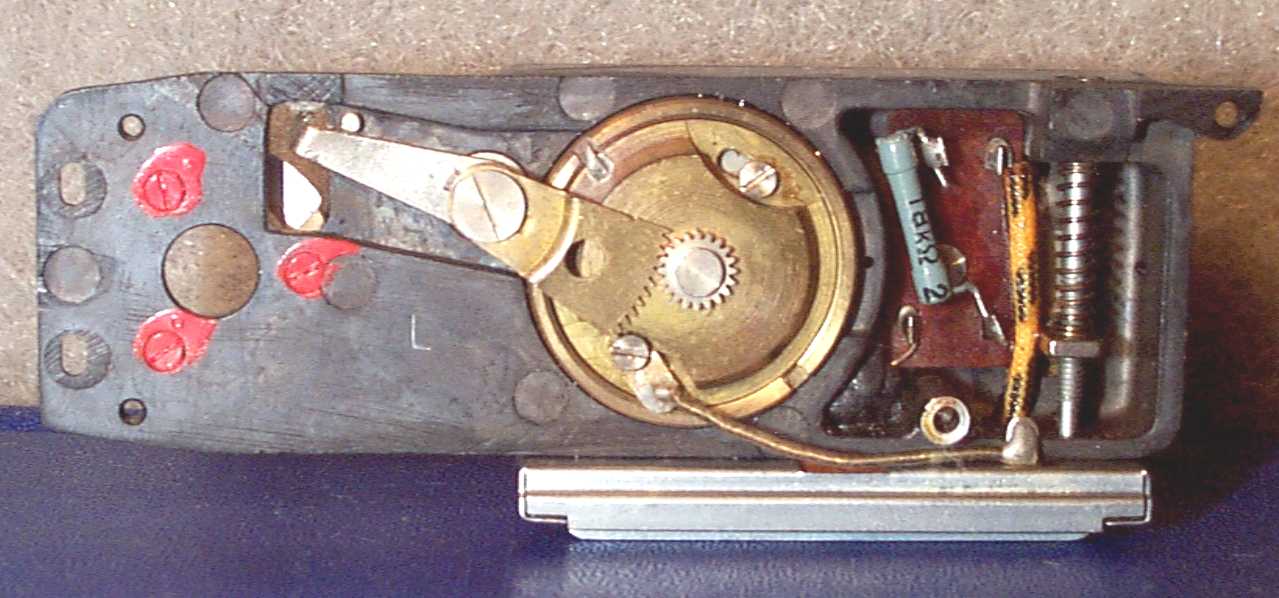

The next picture shows the underside of the shutter module with all the components removed. This view shows clearly the switches and wiring for the flash synchronization system. The blue insulating paint indicates the position of the various switches. One contact is shown loose. This contact is installed when the module is completely assembled. The black cylinder at the bottom center is the PC socket housing.

This next picture is the same view of the same assembly, but with all the component parts installed. Note the blue spots of grease. The special low temperature grease has a blue color. When a camera is winterized, grease must be installed in some locations which are not normally lubricated. This is done to prohibit the introduction of condensation during normal operation which can freeze and block mechanism operation in freezing temperatures. The original factory problem with this camera was that the sliding plate that is located at the left in this picture was slightly warped. This warpage kept it from sliding in its curved slot. This plate must move for the shutter to release. Lapping this plate solved the problem.

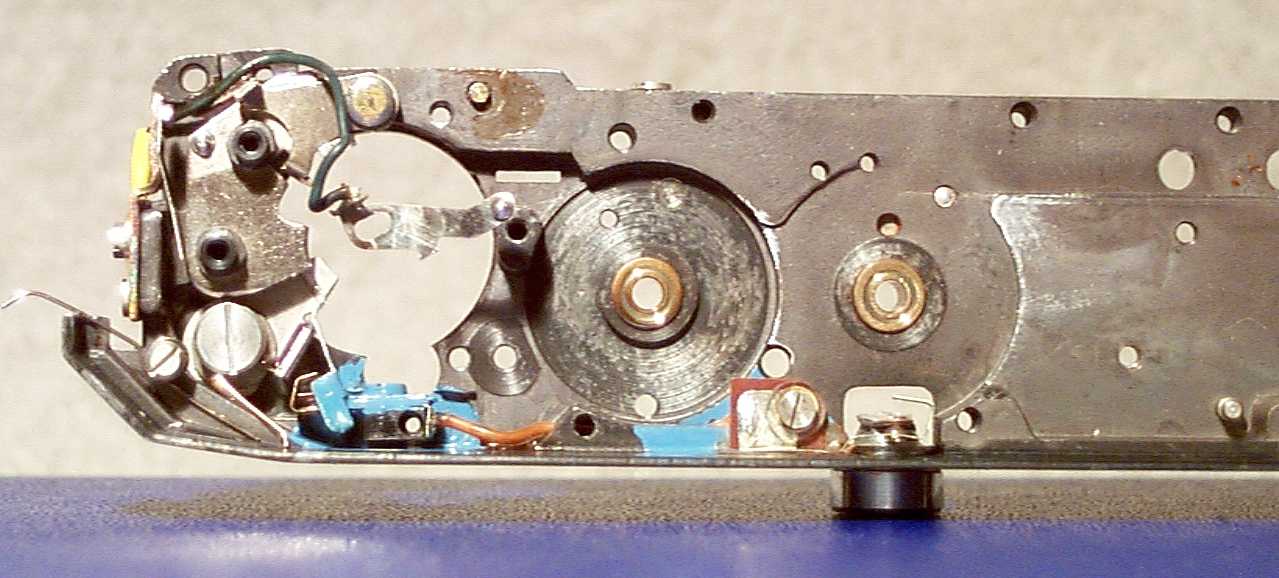

Here is the top side of the same mechanism with all the components removed. Please note the adjustment screw at upper left. This releases the plate directly beneath it to be adjusted. Note the little pin bent up from the plate to the right of the leftmost bearing opening. It is this pin that controls the shutter operation in "B" speed. Wear to the edges of this pin is responsible for a failure of the shutter to hold open when the shutter release is depressed. You can also see the M/X synchronization selector switch at the far right (blue paint). This switch is operated by the shutter speed selector cams automatically.

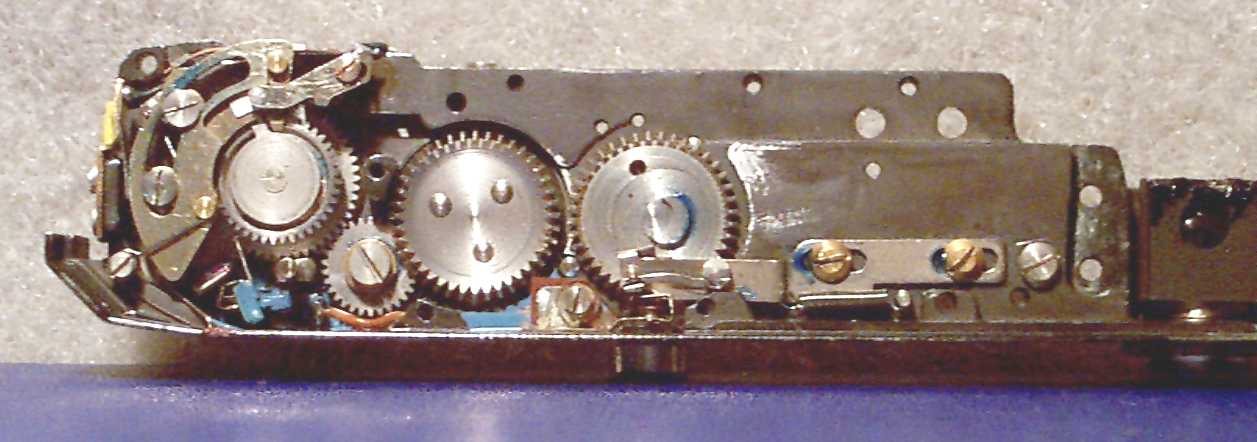

This is a picture of the same assembly, but with most of the parts assembled. The slow speed escapement is not installed. Shutter speed is controlled through a set of two rotating cams. These are located around the film winding shaft. The two cam followers are the shiny steel arms located at the top and bottom of the picture. The shutter release shaft is at the very center of the film wind flange. The film wind flange has three screw holes and is located at the left of the picture.

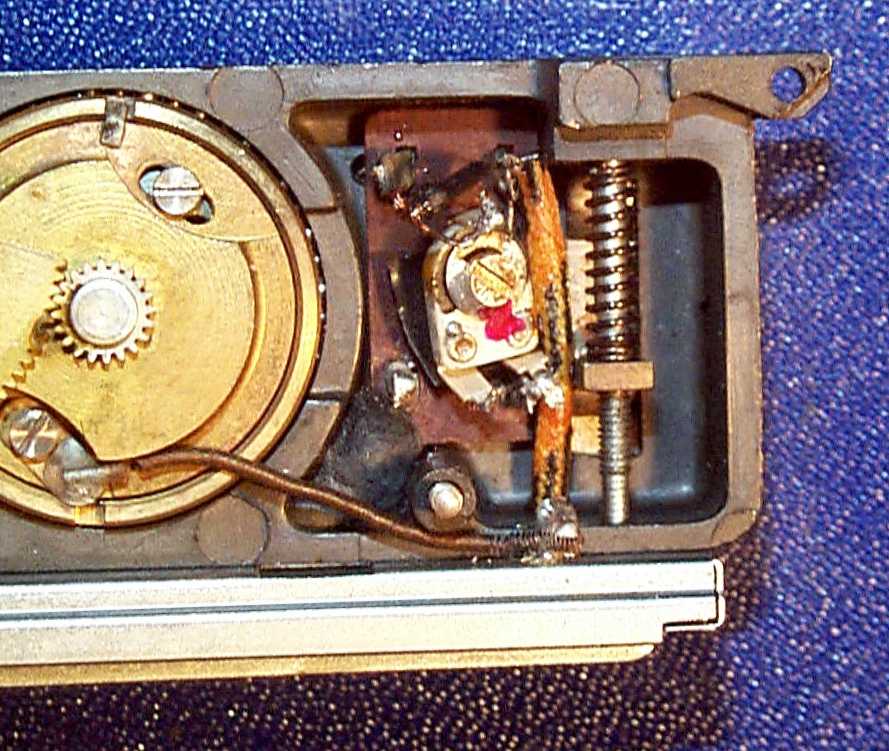

This is a picture of the shutter module shown as it faces the lens, but upside down from its normal position. The self timer mount is on the right.

This is a view from the rear. The fine cords at the right and left control the lower shutter curtain. In the IIa and IIIa cameras, the upper and lower shutter curtains are separately controlled. This is different from the II and III cameras, where the shutter curtains are controlled together.

This is the completed shutter module. The self timer and viewfinder prism are installed. You can see the viewfinder prism from right to left in the center top of the module. Note that the prism on the IIa and IIIa cameras is not straight, but angles down from right to left. The viewfinder prism is made of two pieces that have been cemented together. Many prisms were slightly misaligned when they were cemented and the result of this is that the secondary image is either slightly higher or lower than the viewfinder image. This is an uncorrectable defect at the present time.

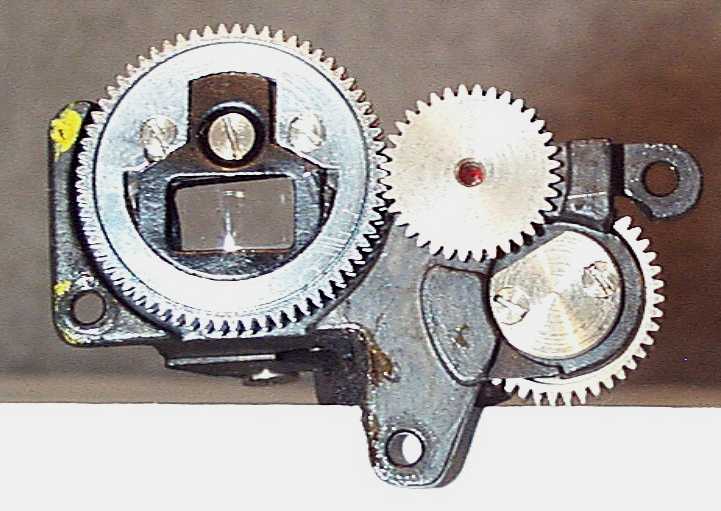

This set of two pictures is of the front and rear view of the range finder module:

In the front view you can see the range finder adjustment ring to the far left and surrounding the range finder front lens. The transfer gear assembly that leads from this ring to the point of mating with the lens mount helical is also shown.

The rear view shows the gear assembly that leads from the adjustment ring to the moving prism lens. You can see the brass gear operated cam and the cam follower from the moving lens assembly. This assembly has been ultrasonically cleaned and so all the metal parts are bright and new.

The next picture is of the range finder assembly mounted on the camera over the prism.

The Contax IIIa light meter is a deceptively complex and extremely delicate mechanism. While all other mechanisms in the camera can take an occasional shock, the IIIa light meter can easily be damaged by an incautious tossing of the camera onto a car seat.

The main problem with the Contax IIIa light meter is the advanced old age of its selenium photocell. The photocell generates a small electrical current when it is exposed to light. It is this electrical current that causes the meter needle to deflect and provide a light reading. The cells in most Contax IIIa cameras are at least 45 years old and have aged to the point of uselessness. The Contax IIIa light meter can be extremely responsive and accurate provided it has a fresh photocell in it. Replacement photocells of a quality high enough for the Contax have only recently become available and I have obtained a supply of them. The following picture is of a typical original Contax IIIa light meter photocell:

You can clearly see the positive electrical contact pads at the right and left. The back of the cell serves as the negative terminal. The black material covering the cell is the element selenium. The electrical contact pads sit on top of the layer of selenium. What you cannot see is a transparent layer of metal that has been evaporated in a vacuum, in the same manner as lenses are coated, on top of the selenium layer. This transparent layer of metal collects the electricity from the microscopic crystals of selenium and transmits it to the conducting pads at the right and left of the cell surface. It is the oxidation and deterioration of this microscopically thin layer of evaporated metal that is the cause of the deterioration of the photocell with age. There is no cure for this other than cell replacement.

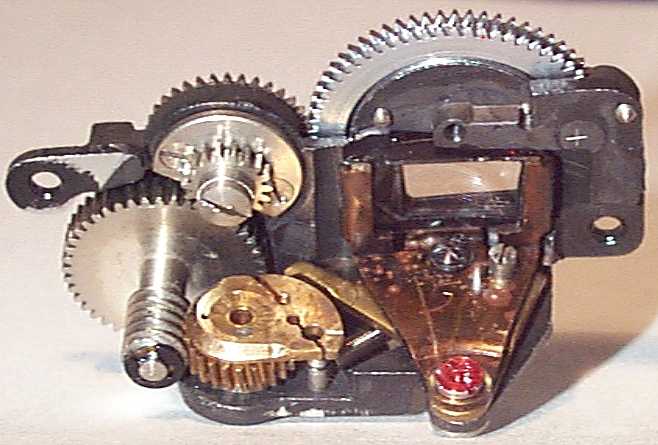

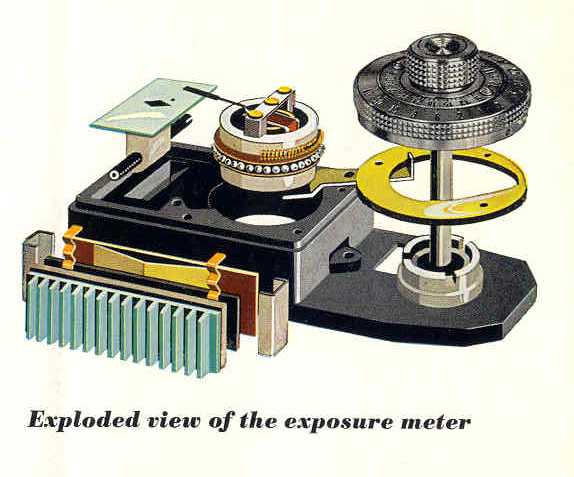

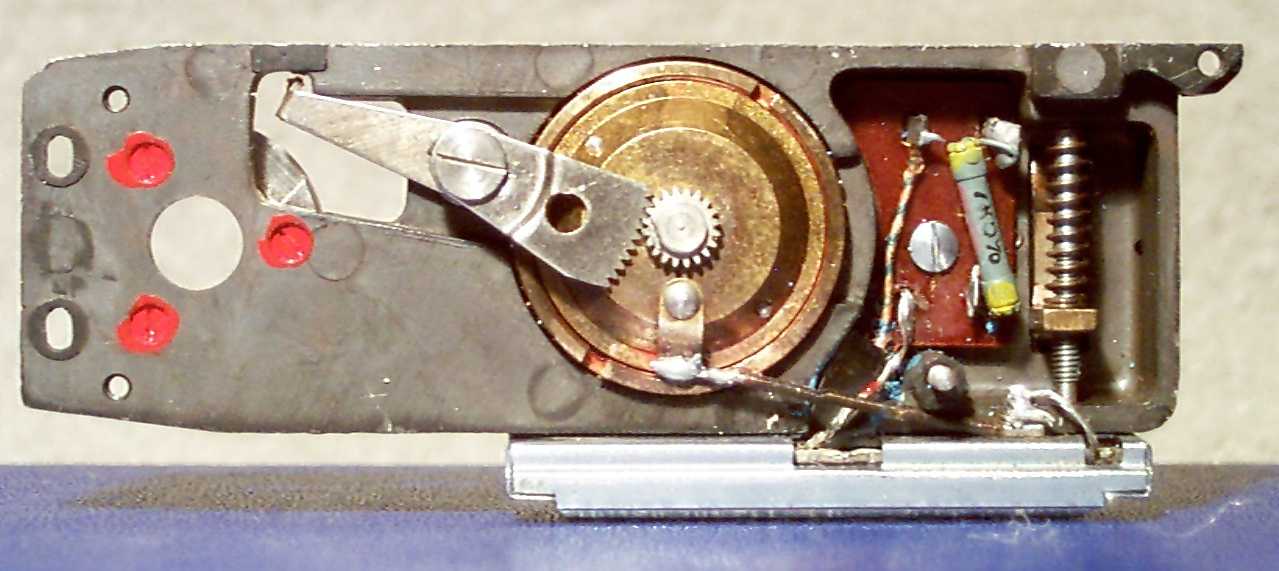

This exploded view of the IIIa light meter provides a clear understanding of how it works. The electrical meter rests in a ball bearing cage. The electrical meter itself is moved by rotation of the adjustment knob through the action of a cammed lever. So there are two movements going on at the same time. The first is the movement of the electrical meter needle in response to the electrical current generated by the action of light on the selenium photocell. The second is the movement of the electrical meter itself in response to rotation of the adjustment knob.

The electrical contact between the cells and the meter can be a source of intermittent or inaccurate operation. There are basically two models of IIIa light meters. The first model, has small friction clips that electrically attach the cell to the meter. Over time dirt, oil and corrosion can reduce or interrupt the electrical connection. Zeiss recognized this problem very late in Contax IIIa production and changed to all soldered connections. In these meters there are small wires which are soldered to the cell and then into the meter. These soldered connection meters are completely reliable and have almost no cell connection type problems. It has become apparent to me that the soldered connection method is the only way to connect new cells reliably to a meter and so it is is my practice, as of January 2007, to modify all Contax IIIa light meters with friction type contact systems so that they are changed to soldered type connections. There is a reasonable fee for this service and this is explained further in the price list.

Occasionally I will come across a IIIa with a light meter that has been worked on by an amateur. The innermost workings of the electrical meter are so delicate it requires the skills and perceptions of a trained watchmaker to be able to work on one without the possibility of irreparable damage occurring. In many cases where an amateur worker has opened the meter covering I have found the meter to be irreparably damaged. Unfortunately, it is not possible to determine if a meter is permanently damaged from an external examination of the camera. Fortunately replacement meters can be installed to correct this situation.

The next picture is of the light meter with the top removed. You can see the long thin indicating needle. This is very sensitive to shock. Many cameras I see require the needle to be very delicately and carefully bent back into normal position. A strong bump or shock to the camera can bend it upward or downward sufficiently so that it will rub and make the meter very inaccurate.

Although hidden beneath the brass "bridge" in the picture below, the indicating needle is attached to a rotating armature that is suspended on two needle point bearings. You can see the bearing mount for the upper bearing in the exact center of the brass "bridge" in the meter below. There is a very fine spring, called a "hairspring" that provides the very delicate tension suspension of the armature so that when the cell voltage increases in response to an increase the the light level, the needle will move upward and then return when he light level lowers. The hairspring is below the center of the brass bridge and also is the electrical connection between the photocell and very fine copper wire coil in the rotating armature. The hairspring has great strength when the armature is moved in a direction that coils it tighter, but it can be permanently bent if the rotating armature is rotated backward.

Please take careful notice of the long small copper coil spring that surrounds the left half of the outer circumference of the meter mechanism. This coil spring is the key to how the meter is adjusted by the meter adjustment knob. When the adjustment knob is rotated a mechanical lever causes a gear train to rotate the outer part of the electrical meter to bring the needle into alignment with the diamond mark on the meter face. So there are two moving parts in the electrical meter. In inner rotating armature and the external rotating magnet. The internal armature rotates and moves the needle in response to light, and the external magnet moves in response to changes in the adjustment knob position. It is the outermost copper coil spring that tensions the adjustment mechanism. The brass bridge is connected to the magnet by the little bolts at each end, so the magnet and the rotating armature are mechanically connected through the hairspring. And it is this connection that is the key to understanding just how easily the IIIa light meter can be destroyed.

You can also see at the upper right the small gold plated brass connection of the friction type cell connector.

This is a picture of the underside of the type 1 IIIa light meter module. You can see the adjustment screw on the upper right of the of the brass barrel of the lower meter housing. Note also that the cell connection is with a screw. These, in addition to the manner of cell connection, distinguish the type 1 meter from the type 2.

You can clearly see how the lever rotates the magnet through a gear connection. As the adjustment knob is turned, the lever shifts position and this causes the gear to rotate the magnet. The meter hairspring will be excessively uncoiled so that it is permanently snarled and the meter is destroyed if the lever is removed and the brass barrel in the picture below is allowed to rotate backwards.

The brass barrel rotates over a set of 24 small steel ball bearings. Notice that the photocell is electrically connected to the brass barrel through a very fine copper spring. The electrical connection between the brass barrel and the upper meter electrical mechanism is the bearing balls. When these become coated with deteriorated grease and oil from the adjusting knob mechanism the electrical connection can be broken, become intermittent, or have increased electrical resistance resulting in meter inaccuracy.

Please notice that the brass barrel in the Type I meter has two steel screws at the top and bottom. These allow for the position of the magnet to be adjusted without removal of the lever. I find fewer destroyed Type I meters than I do Type II meters. There is a good reason for this.

This is a picture of the underside of the type 2 IIIa light meter module. The Type 2 module is distinguished by the riveted cell connection at the lower brass barrel of the lower meter housing and soldered cell connections.

Please notice the absence of the adjustment locking screws. The only way to adjust the Type II meter to a new cell is to remove the lever and set the brass barrel to a new resting positron. This is a very dangerous thing to do since removal of the lever without a tight control over the barrel will cause the barrel to over rotate backwards under the tension of the internal copper coil spring resulting in permanent damage to the hairspring and destruction of the meter.

Zeiss recognized this problem, and the last set of III cameras manufactured in 1963 contained a variable electrical resistor on the circuit board which allows the meter to be accurately set without removal of the lever. It is my practice to install this variable resistor in every meter that is overhauled here. This modification is included in the cost of a light meter overhaul. This picture shows this resistor:

This meter was defective from the factory and had never functioned properly. The defect was an electrical short between the meter cell connection and the meter module body. This short was located beneath insulating paint and was difficult to find.

Here is a top view of the same meter. You can see how the adjusting lever is positioned to fit into the cam underneath the adjusting knob.

IIIa Light meter Doesn't Respond to Light?

A large number of IIIa light meters no longer respond to light at all. In more than 90% of these cases, the problem is a completely dead old photocell. Even if the meter responds to light, if it has its original photocell it is most likely not responsive enough to provide meter accuracy. Most old cells I see are at least 2.0 f stops inaccurate. I have in stock brand new photocells. These new photocells incorporate the latest technology in selenium light sensing cells and have a longer life, are more responsive, respond to changing light levels faster, have a more linear output, and are an exact replacement for the original cells in fit and finish. In most cases, all that is required to bring your light meter back to better than like new performance is a servicing and the installation of a new photocell.

If your meter has mechanical or electrical problems that can be corrected without the need for replacement parts, this work is done without additional cost. All work necessary to return the meter to better than original accuracy is included in the cost of a new photocell. This includes cleaning, lubrication, and precision adjustment using a Honeywell precision light source and a Spectron Camera Tester.

Some light meter designs used in early camera production by Zeiss have electrical connection problems caused by friction type electrical connectors. It is now my practice to modify these type meters to have soldered connections. This is the only way to ensure complete reliability. The point is to provide you with an accurate, responsive and completely reliable light meter on your IIIa camera.

Less than 1% of meters have been damaged beyond repair. Usually this has happened by the meter being opened by unqualified persons. But even if the meter internals have been severely damaged, in most cases satisfactory repairs can be made. Regardless of the amount of work required to repair your meter, it is all covered by the one time fee for replacement of the cell.

If your light meter should be damaged beyond repair I have reasonably priced replacement meters available in stock so your camera can always be returned to better than like-new performance.

It is very common for people to make the observation that the needle on a IIIa light meter to stick on the bottom and require a light tap in order for it to respond to light. This behavior is actually not a problem at all, and it is easily eliminated.

The natural inclination is to operate the light meter with the adjustment knob kept rotated fully clockwise when the meter is not in use and the cap is closed over the photocell. The proper way is to keep the adjustment knob kept in the fully counter clockwise position. When this is done, and the photocell cap is opened, the needle will immediately move to the top of the range and it will not stick. Then, the adjustment knob is rotated clockwise to bring the needle to match with the point on the diamond.

When the adjustment knob is kept in the fully counter clockwise position the needle will indicate on the dot just below the diamond if it is adjusted properly when the photocell cap is closed. When the needle is on the dot it tells you the mechanical parts of the meter are adjusted properly. So keeping the adjustment knob in the fully counter clockwise position always gives you a check on your meter condition.

The reason the needle sticks when the dial is kept in the clockwise position is simple. When this is done the indicating needle is held tightly against the bottom stop. This cocks the armature, to which the needle is attached, in its bearings. When the adjustment knob is moved it takes a relatively large amount of rotation or a slight tap on the meter to free the needle bearings so that the armature can freely rotate and the needle can indicate.

So keep your adjustment knob rotated fully counter clockwise and everything will indicate smoothly and properly.

Zeiss made a lot of changes to the light meters during the years they were produced. For the most part these changes were made to the parts that make the electrical connection to the photocell. In the first models Zeiss used friction contacts made of copper to make the connections to the contacts on the front of the photocell, and a nickel plated contact to make the electrical connection to the back of the cell.. But the copper surface quickly corroded and this caused intermittent connection problems. Then the copper parts were gold plated, but then the nickel parts would corrode after a longer time and this would cause intermittent connection problems. Finally Zeiss used all soldered connections. This solved the intermittent connection problems. Most of the light meters that were produced have mechanical friction type connections.

If your light meter is having intermittent operation problems these can be solved by having your meter modified to be like the last production type meters with soldered cell connections. All Contax IIIa light meters with friction connections that are overhauled here are modified to have soldered connections.

If your light meter is having intermittent operation problems and you want this problem solved permanently, write to me.

The photocell provides the electrical current in response to light that makes the light meter needle move. The Contax IIIa light meter photocell is a thin metal sheet that is coated with the element Selenium. Selenium gives off electrons when it is exposed to light. The electrical connections to the photocell are made by making one electrical connection to the back of the photocell. An electrical connection to the back is easy because it is made of steel coated with a layer of silver. The connection to the front is much more sophisticated, and this is the reason photocells age and die. The front surface of the selenium layer is coated with a transparent layer of conducting metal, usually silver. This layer is applied in a vacuum where tiny amounts of silver are vaporized which then condenses on the surface of the photocell. This coating is in the same manner whereby anti reflection coatings are applied to lenses. Over time the thin layer of metal is attacked by oxygen in the air, and slowly with time it becomes less and less electrically conductive. This process of deterioration takes many years. But it is the reason that by now most, if not all, photocells installed in IIIa light meters are at the very end of their lives. It is not possible to rejuvenate a photocell by applying a new coating since this would only apply a good coating over a bad one. The best thing to do is to replace the photocell.

The Contax IIIa meter is highly sensitive and accurate. With a new photocell installed it is fully capable of supporting the use of films with the most narrow exposure latitudes such as Kodachrome or other reversal color films.

Color Dial or Black Dial Camera?

Zeiss made two models of Contax IIa and IIIa cameras. These are called the "Black Dial" and "Color Dial" models. The term color dial or black dial refers to the color paint that was put into the engraved speeds on the shutter speed dial. The black dial models has all the speeds filled in with black paint, and the color dial had the colors black, yellow and red.