Information

- Services

- Scheduling Services

- Waiting List Info

- Guarantee

- What is a CLA?

- What a CLA leaves out

- Purchasing a Contax Camera?

- Camera Equipment Sales

Cameras Serviced & Pricing

- Contaflex TLR

- Contarex Bullseye

- Contax I

- Contax II and III

- Contax IIa and IIIa

- Zeiss Lenses

- Kiev Cameras

- Contaflex SLR

- Kyocera Contax

Overhauls

Lens Services: In most cases lenses are serviced outside of the normal waiting list and a typical overhaul will require only about two weeks or less to accomplish.

Lenses That are Overhauled Here:

I overhaul every Zeiss lens. This includes lenses for the Contax RF, Contax SLR, Nikon RF, Carl Zeiss and Carl Zeiss Jena lenses and lenses by other makers for other cameras. If your lens is not listed on this page and you want to know if it can be overhauled here and the cost please use this email link to contact me:

Lens Overhaul Prices and Turaround Time:

If you have a lens that needs an overhaul or to be repaired and you want to know the price and turn around time please use this email link to send me an email about it and I will reply promptly. Please send me all the information you have about the lens and describe the problem that causes you to believe the lens needs an overhaul or repair. In the case of most overhauls a firm price can be provided.

Lens Overhaul or Repair Cost Question Email

The Reason an Old Lens Needs a Complete Overhaul:

All lenses contain grease to lubricate the focusing and/or aperture control mechanisms. Grease is made of oil and other ingredients that cause the oil to form a solid so that it will stay where it is applied. Over time the grease begins to degrade and it will release this oil. The oil moves into the lens and coats the glass internal lens elements. Lenses must be absolutely clean in order to do the job each lens element in a lens is designed to do. A lens full of oil coated elements will not focus precisely nor will it render colors as it was designed to do. This oil is also food for mold. The mold eats the oil and exudes acid as a by product. Depending upon the mold it can exude acid strong enough to etch coatings and glass. This is why it is necessary for a lens to be completely overhauled with each and every piece of it thoroughly cleaned and disinfected. It does no good to superficially service a lens by pouring oil into it or by merely cleaning the lens elements. Fungus spores can reside deep inside a lens and continue to grow in one that has not been completely disinfected. All lenses overhauled here are completely cleaned. Any lens over 20 years old should be considered to be old enough to need an overhaul. The fact that oil may not be visible on the aperture blades may merely mean the grease in the lens released all of its oil a long time ago. How fast the grease in a lens will degrade depends upon its storage and use conditions.

The Reality of Manufactured Lenses. Lens Testing and an Overhaul:

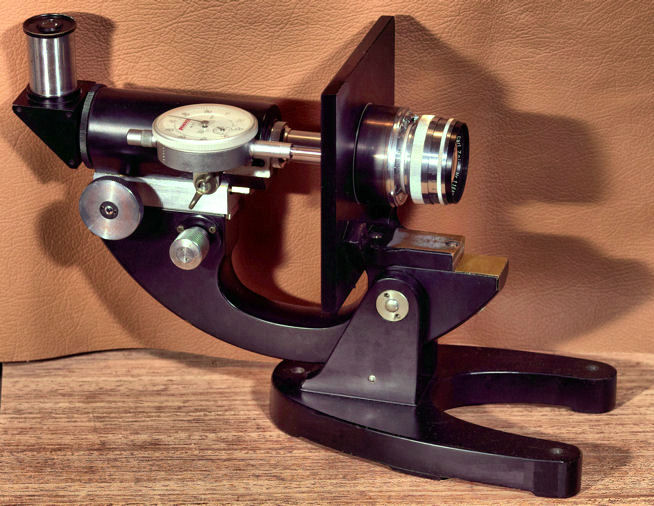

Over the years I've had the opportunity to examine thousands of lenses for every kind of camera and all of this experience suddenly distilled itself into two thoughts about lenses that is the most important thing for anyone to know when selecting one to buy. This is simply the one single most important thing about a lens is the optical glass used to make it. Everything else is just window dressing. A lens is just like any other manufactured product. The better and the more expensive the raw materials used to make it the more effort and craftsmanship will be expended on the fine details of manufacture. No one can imagine a lens maker putting $1000.00 worth of labor into a lens made with the cheapest grade of optical glass. But, if you look at all the advertising ever printed about every lens ever made you read nothing about the optical glass used in the lens. There is absolutely nothing. A couple of years ago I read an interview with the owner of a company in Japan that manufactures lenses with a very high name engraved on them. In this interview he said that his company only used the best optical glass for prototypes and then used lesser quality glass for production lenses because "the customers don't notice it". The second thought is that since nothing is written about optical glass and the lenses the best grade of glass is used in the only way to go is to test. The problem is this takes custom made machines that only lens manufacturers can afford to make. Fortunately one of these came up for sale on Ebay and I bought it. Here's a picture of the lens microscope made by the Canon camera co.:

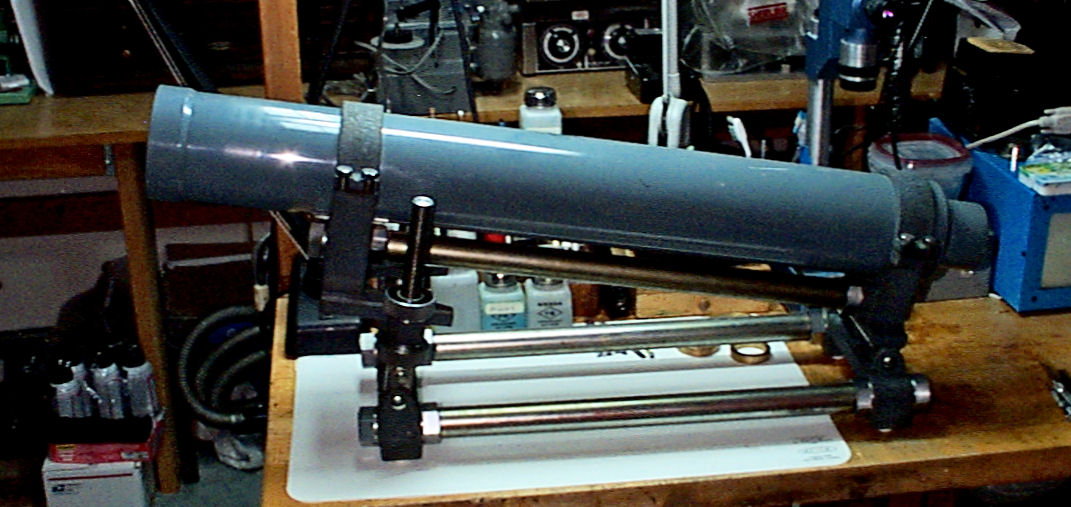

This lens microscope is shown with a postwar T coated 50mm f1.5 Sonnar lens mounted on it. This microscope allows me to view the sharpness of lenses, at high magnification, when they are sighted at a high resolution target in this three foot long super high precision optical target collimator that was made to match with this lens microscope:

This lens evaluation equipment was manufactured by the Canon camera co and is labeled for "Factory Use Only". I believe it was used to evaluate prototype lenses designed for the Canon line of Rangefinder cameras and was custom made by them for this purpose. This equipment has allowed me to come to one conclusion and this is that Zeiss used only the highest possible quality optical glass in the lenses they made for their entire range of cameras including the Super Ikonta, Contax and Contarex. They held nothing back and engaged in a process of continuous improvement. Everything else I've seen is just not quite as good. You can spend $2000.00 for a strangely named lens or other oddity but the fact is when it comes to optical performance there are only two things to look for on a lens. This is "Carl Zeiss" and "Made in Germany". These days there is a superstition against postwar Carl Zeiss Jena lenses. These lenses are optically just as good as West German made Carl Zeiss branded lenses except that they are made of aluminum whereas the West German made lenses are made of chrome plated brass.

If you would like to read everything Zeiss ever divulged about the making of lenses, and it is quite a lot of very valuable information, you can use this link to download the Zeiss booklet, "Photographic Lenses and How They Are Made" published in 1928:

If you would like to know just about everything that can be known about modern optical glass please use this link to access the article "Optical Glass" published recently by the Edmund Optical Company. It is very comprehensive:

Edmund Optical Article "Optical Glass"

If you would like to know just about everything that can be known about modern optical coatings please use this link to access the article "Anit Reflection Coatings" published recently by the Edmund Optical Company. It is very comprehensive:

Edmund Article "Anti Reflection (AR) Coatings"

This Zeiss Article posted on the Carl Zeiss Web Site is a 33 page PDF document explaning everything you ever wanted to know about photographic lenses and what makes a good or bad lens. This article is about as definitive and complete as can be and is weill worth reading:

Zeiss Article "Reading MTF Curves"

The one remaining big secret about old lenses is the optical glass used in them is vastly superior to the optical glass available today. The reason for this is modern safety and environmental regulations have resulted in the removal of both lead and arsenic from modern optical glass. The removal of these ingredients has had a very strong effect upon the quality of optical glass available making lenses made with optical glass that contains arsenic and lead to be very superior. Right now, given the resolution limits on digital cameras this lower quality optical glass does not produce digital results that are visible. But, in time, and with decreases in pixel size it will become evident.

Also, there are various grades of optical glass. Optical glass can cost the same as gold and so only the best lenses get the best optical glass used in them. There is a famous maker of lenses today who admitted in an interview some years ago that they used the best optical glass only in their prototype lenses and used less good glass in their production lenses. This is not true for classic Zeiss lenses. Zeiss has always used the best possible optical glass in all of its lenses that are made in Germany.

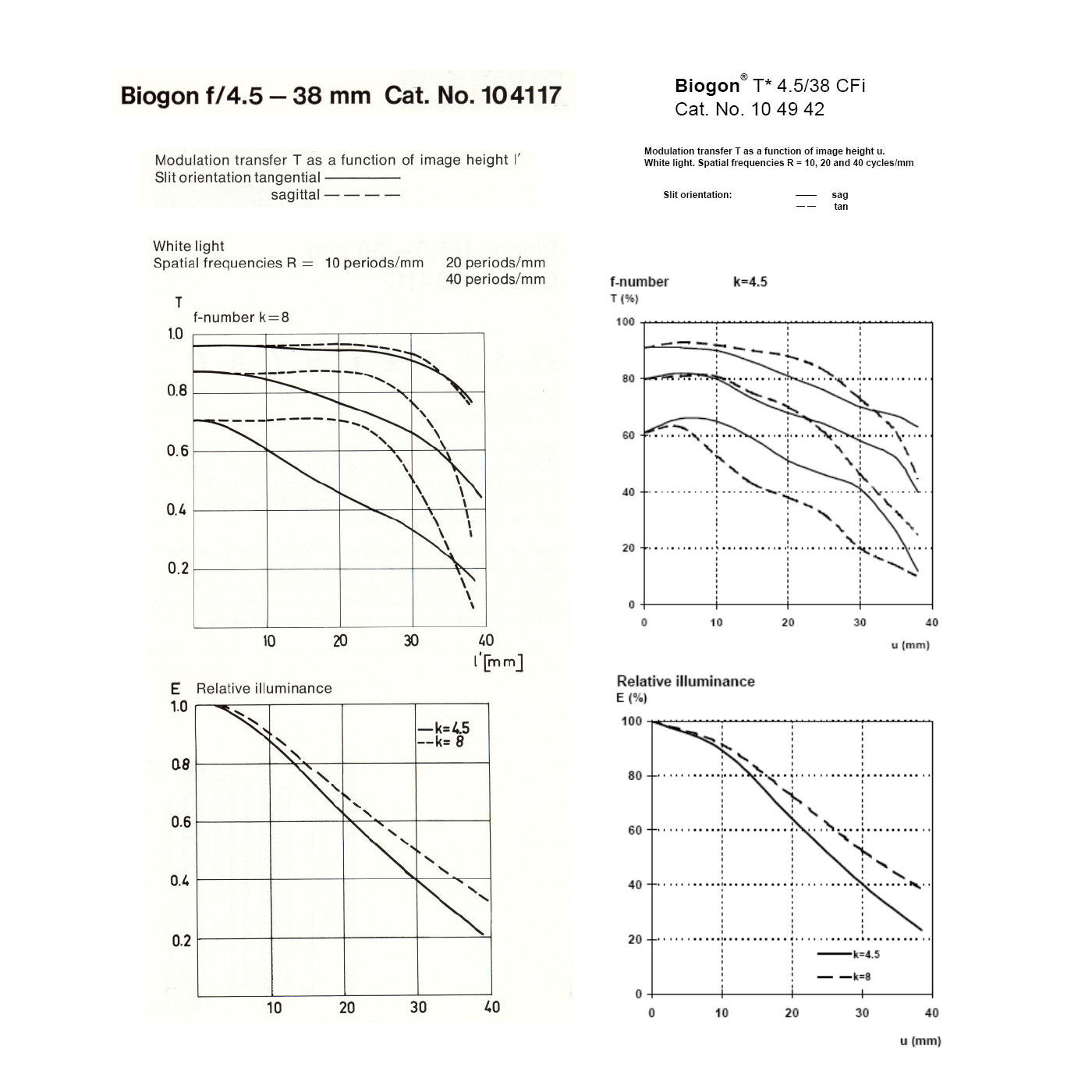

Optical glass making is completely ruled by trade secrets. Little is known about it by persons not directly involved in its manufacture who are bound by iron-clad secrecy contracts.. But it has been disclosed that small amounts of various metals, some toxic, improve optical glass. The problem is modern safety regulations prohibit the use of some of these metals in optical glass manufacture because the metals are toxic. This has resulted in a reduction of the overall quality of optical glass used in the making of lenses. This quality decline has been obscured in recent times by the fact most modern made lenses are being used on digital cameras and so it cannot be seen.....yet. You can be sure if you buy a German made Zeiss lens made prior to the formation of the European Union you are getting the best possible optical glass that can be made. This is demonstrated by the Modulation Transfer Curves (MTF) or sharpness curves published by Carl Zeiss for the legenday super premium Hasselblad 38mm Superwide Biogon lens:

The curves on the left are for the early Biogon manufactured with optical glass containing arsenic and lead. The curves on the right are for the last Biogon manufactured without arsenic and lead in the optical glass formula. As you can see the early lens has much better MTF (sharpness) curves than does the last version lens. If you would like to view the complete individual reports published by Zeiss for the three Hasselblad Superwide Biogon lenses you can use these links:

Hasselblad Early 38mm Biogon (C)

Hasselblad Middle 38mm Biogon MTF Curves (CF)

Hasselblad Last Moden 38mm Biogon MTF Curves (CFi)

I've seen some Zeiss lenses that have taught me a big lesson about lens performance. The most recent was a Contarex 18mm Distagon. This is a very complex lens made up of nine groups. A customer sent me his 18mm Distagon lens for an overhaul and at first examination it looked bad. It could plainly be seen that the inner lens elements had lots and lots of grinding defects. When the lens was disassembled there was even one element covered with very severe grinding defects in a square cross hatch pattern that were so deep they would catch a finger nail. But when all the elements had been cleaned and the lens reassembled and it was collimated it was without a doubt the sharpest performing lens I've ever seen. The owner himself wrote me about a year later to say that the performance of the lens astounded him and it was his sharpest Contarex lens by far.

The lesson of all this is that you cannot possibly judge the performance of a lens by its cosmetic appearance. There is a famous instance where an astronomer who purchased a very large Zeiss telescope made a complaint to Zeiss about the bubbles in the lens glass. The reply he received was "Lenses are for looking through and not for looking at".

The ugliest lenses can, and often do, provide the highest possible level of photographic performance. The conclusion I've been led to by years of peering through Zeiss lenses is that while a cosmetically perfect lens will do the best on the marketplace, the more the bubbles the better the pictures the lens will produce. If you're looking for pure Mokeh and you have to bet on a lens, bet on the Zeiss lens with the most original factory defects.

I get many comments from people so see things inside their lenses such as wipe marks, spots, bubbles in the glass, scratches, and just about anything else the eye can see. The simple fact of the matter is that lens making is a thing shrouded in manufacturing secrecy, trade secrets, secret formulas and a lack of factual information. No lens manufacturer has ever stated that the lenses they make will be completely free of any kind of observable thing. Manufacturer's typically provide only lens performance charts and this is all there is. It is normal for a typical lens, and in particular an older lens, or a high tech. lens made of superior optical glass, to have some bubbles in the glass, discontinuities in coatings, spots in coatings and other flaws such as grinding marks of various kinds. Optical glass is very expensive to make and in the case of very high tech. lenses from premium manufacturers such as Leitz and Zeiss, very rare and expensive pieces of optical glass containing obvious visible defects were often used to make lenses because it was impossible to get glass that didn't have both defects and highly desirable optical properties at that time.

Many people like to observe their lenses by shining a bright light through it from the rear and then examine it with a magnifying glass or a microscope. There is no authoritative lens testing book I've ever seen that has described this test. The reason for this is that lenses are sold based on performance and not on the individual cosmetic beauty of the elements that are assembled together to make the lens. Lens elements can have significant coating and/or grinding marks on them and when assembled in a lens produce a lens that has tremendously great performance. Paradoxically, cosmetically perfect lens elements can be assembled into the same lens and produce a worthless piece of junk. Premium lens makers assemble their lenses using individual elements that produce the best results from the lens as an assembly and this means that sometimes individual elements may not have as much cosmetic beauty as others, but their optical performance is highly superior to others.

A dirty lens, when examined from behind with a bright light and examined from the front with a magnifying glass will have a superior internal cosmetic beauty to one that has been very carefully cleaned. It is for this reason that there is absolutely no guarantee of any kind with respect to any before/after defect or object anyone may see when a lens is examined by this method, sent here for an overhaul, and then reexamined using the same method. My advice to you, if you are married to his method of examining lenses, is to please take your lenses to someone who you are sure will take your money and will do nothing other than to wipe off the outside of the lens and then return it to you. My policy is to not respond directly to any comment, question or observation about a lens examined by this method other than to direct the person to this paragraph.

When you send a lens here for an overhaul it will be completely disassembled. Each and every part and lens element will be cleaned multiple times in several solvents. Each lens element will be examined carefully and will only be reinstalled unless it is totally clean. Then the lens will be lubricated, assembled, adjusted and collimated. There are no short cuts or abbreviations. The purpose of an overhaul is, to the maximum possible extent, to return your lens to factory original condition or better.

The lens overhaul process has been expanded to include the use of Swiss made Fixodrop lubricant fixative inside lenses. This is a treatment that is brushed onto clean and oil free metal surfaces. It blocks the movement of oil or grease across any surface treated with it. It does not expire, degrade, migrate or wear out. It's a permanent treatment.. Fixodrop is applied where necessary to keep aperture lubrication in its place so that it does not migrate over time into other parts of the lens such as lens element surfaces and aperture blades. Fixodrop is tremendously expensive, but it is used liberally and is applied lavishly inside your lens so that your lens will retain the superior optical performance that comes from extreme cleanliness of the lens surfaces, the aperture blades move freely, and the lens moving parts stay properly lubricated for a great many years.

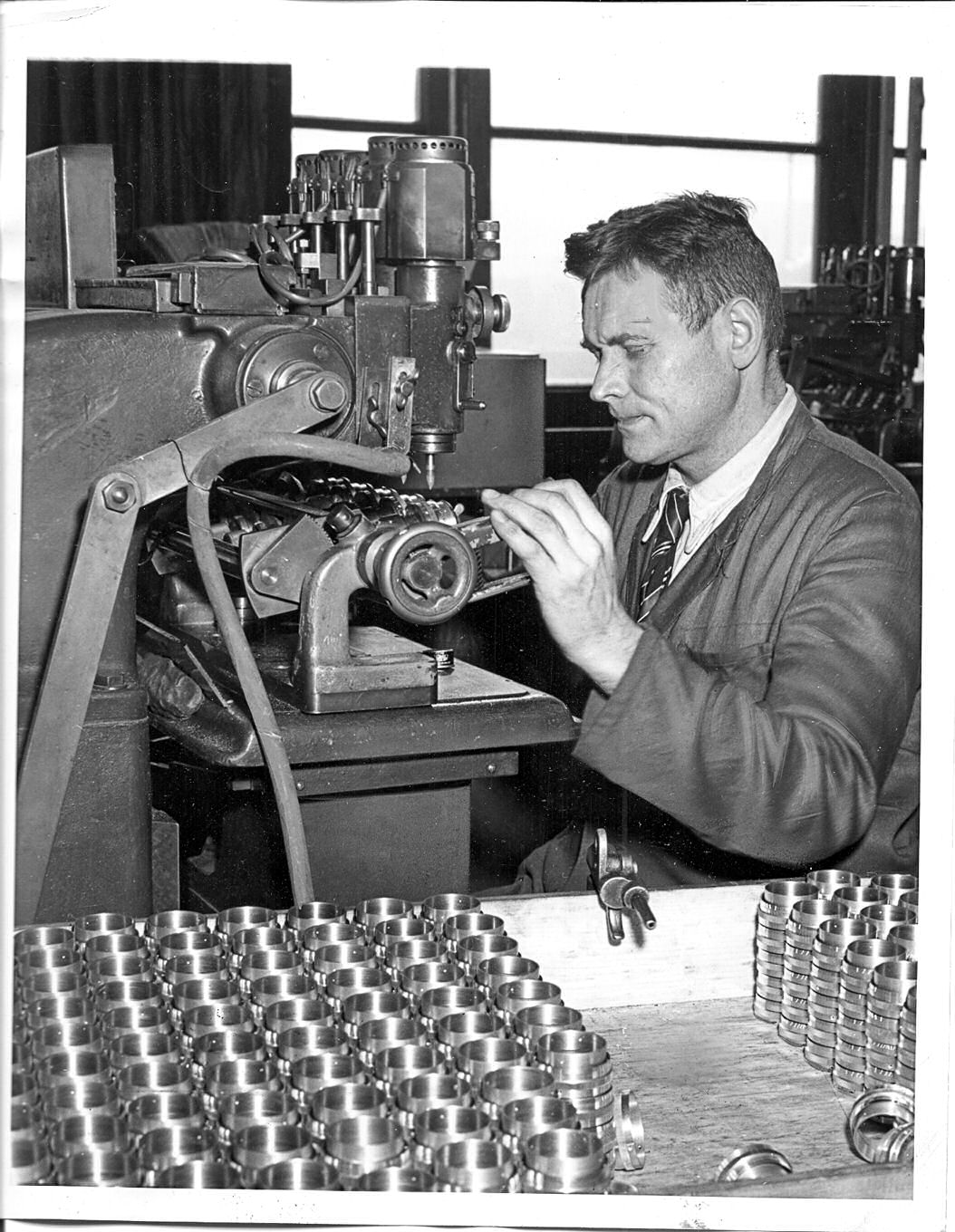

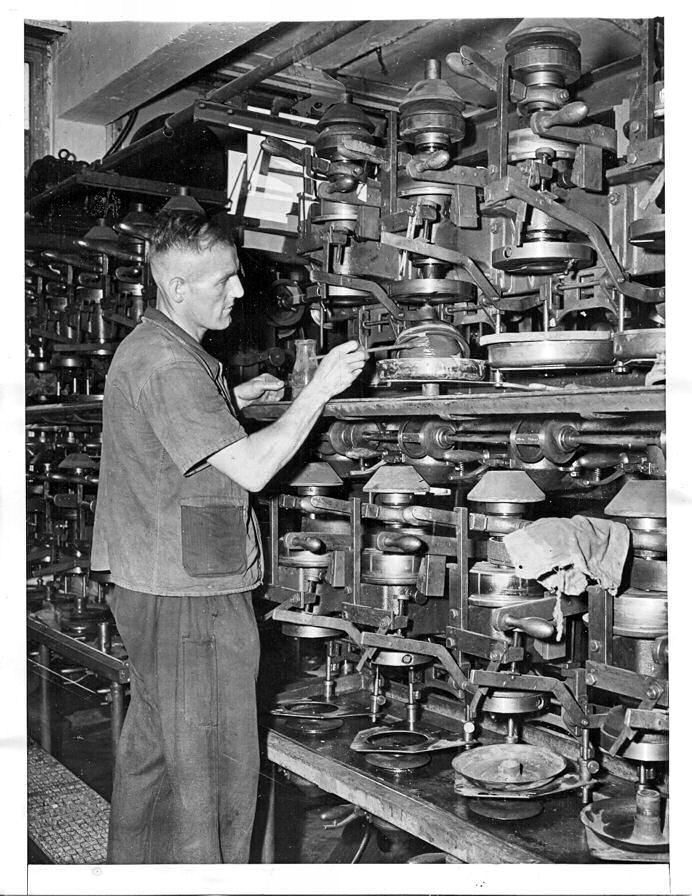

This is a picture taken in the Zeiss Jena lens factory in 1946. It shows a technician using the machine that produces the knurled ring around the upper lip of the Contax 50mm Sonnar lens.

\

\

The caption on the back of this picture reads:

ACME PHOTO SERVICE FOR IMMEDIATE RELEASE 5/10/1946. "This worker is assembling Zeiss lenses prized by shutterbugs the world over with 10,000 workers on the job, the Zeiss Plant is operating at all most full scale prewar levels. Some of the cameras turned out here will be bought by the U.S. Army for PX distribution." It should be noted that the Russians had confiscated 93% of the Zeiss machinery in Germany as war reparations and so the statement the Zeiss Plant is operating at pre war levels of production had to be overly optimistic. Obviously the fact the picture shows that lenses for the Contax camera were being produced demonstrates that Zeiss was producing the Contax, today called the "Jena Contax" at this time.

Filter Ring Dents and Dings:

There's nothing quite as tragic as a wonderful lens whose appearance has been ruined through the use of a lens vise or pliers to "repair" a filter ring ding. Here special tools are used to gently bend the bent metal back into shape so that in most cases the repair can be done without any sign that there had been a ding to begin with. Here are before and after pictures of a worst case lens:

The filter ring is the same. It was straightened and the filter threads brought into perfect alignment with each other through the use of this special tool. This tool is tapered so that even the most deeply distorted filter ring can be threaded onto it and then moved downward and gently worked to straighten out the dings and dents and align and form the threads without affecting the original paint. There are no pliers or other marks on the filter ring.

Even if your lens is not a 50mm it is possible to make a special tool to suit it so that the best possible repairs can be accomplished. If a special tool is needed for your lens you are not charged for it.

Epoxy and Balsam Cemented Lens Separation Repair:

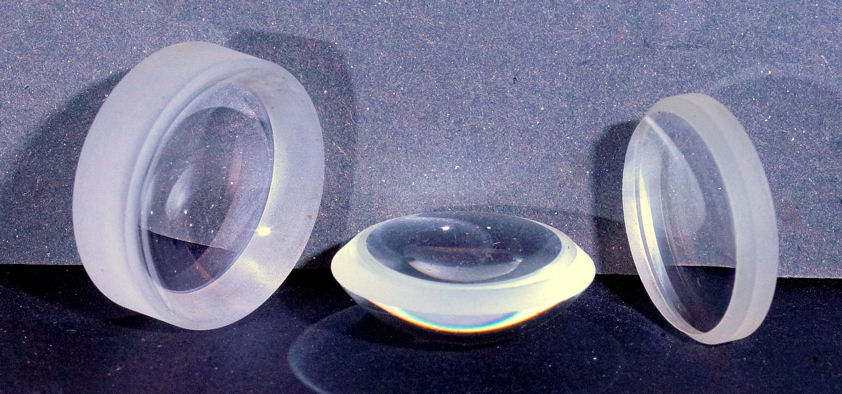

It is possible to permanently and safety correct the most common Zeiss lens problem and this is the separation of epoxy cemented lenses. The following two pictures show before and after views of the same center triplet element from a Carl Zeiss Sonnar 50 mm f1.5 Lens with cement separation.

The process does not affect the coatings, lens centering, element alignment or any other optical attribute of the lens other than the separation. The procedure is permanent and does not use oil of any kind. The lens is actually separated into its component elements and then re cemented using a modern lens cement. The Separation process does not affect the original coatings or any other lens property. Unlike other separation processes that use great heat, remove the coatings, and require re polishing and re coating at great cost; the separation process used here has absolutely no effect on the lens or its coatings. Only the original lens cement is removed. You can clearly see the lens is much clearer and color free than it was before it was re-cemented. All lens cements from the past deteriorate and separation is only the final stage of deterioration. The cement will discolor and become opaque and will degrade the lens performance very much.

Here are three pictures showing an 85mm f2.0 Sonnar lens rear element with severe internal hazing and clouding caused by deterioration of the original epoxy lens cement. The first picture is of the lens element in its original condition. The arrows show the edge clouding and browning.

This picture shows the lens removed from its mount and separated into its three component elements:

This picture is of the lens element, back in its mount, re cemented and ready for use:

The lens cement used is the latest high technology very slow curing military specification type. It has a higher index of refraction than previous generation cements, and this provides greater lens coupling with less internal dispersion resulting in greater lens clarity and brilliance providing greater color correction, sharpness and contrast. This is the lowest stress lens cement there is and this low stress further reduces the internal lens dispersion and enhances coupling.. it is is much clearer and will not discolor under high temperature. It is also highly shock resistant and does not over harden as the old epoxy cements do. it is just the best that there is available anywhere.

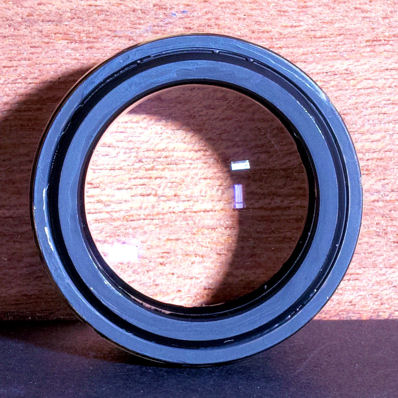

Here is a picture through a Carl Zeiss 50mm f1.5 Sonnar that has had both of its cemented elements (middle and rear) separated and re cemented with the new high tech. lens cement::

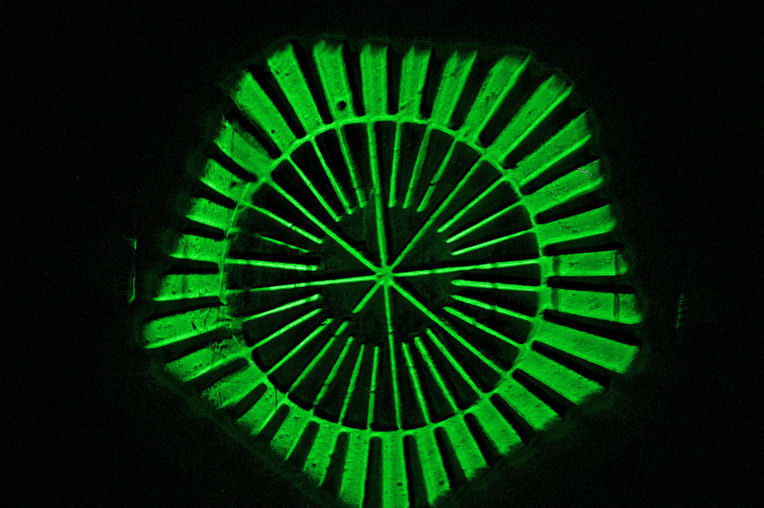

This is a picture taken through the eyepiece of the autocollimator when evaluating this lens:

The pentagon is shape is due to the iris of the lens used to take the picture through the eyepiece. What you see in this picture is that the center circular section with its very sharp thin lines demonstrates the super super sharpness of the re cemented Sonnar. The sharpness of the outermost fringes show that the field of the lens is totally flat and there is absolutely no distortion.

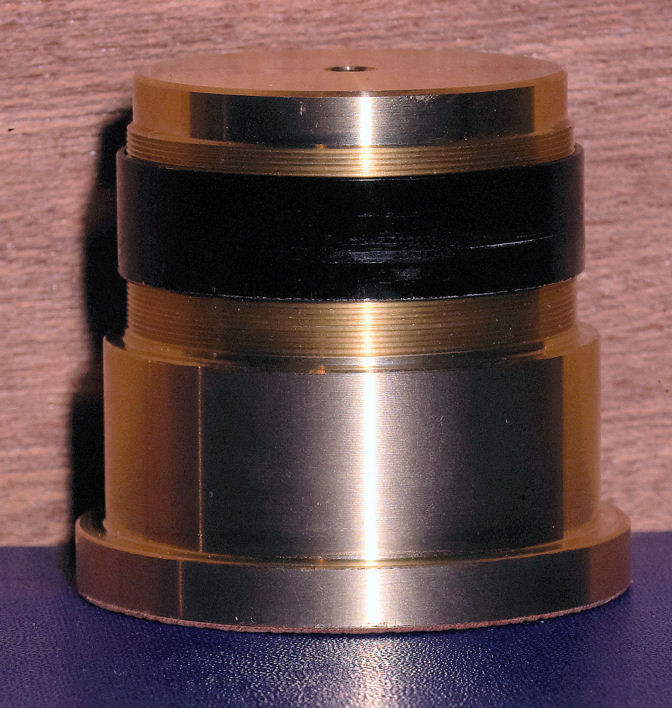

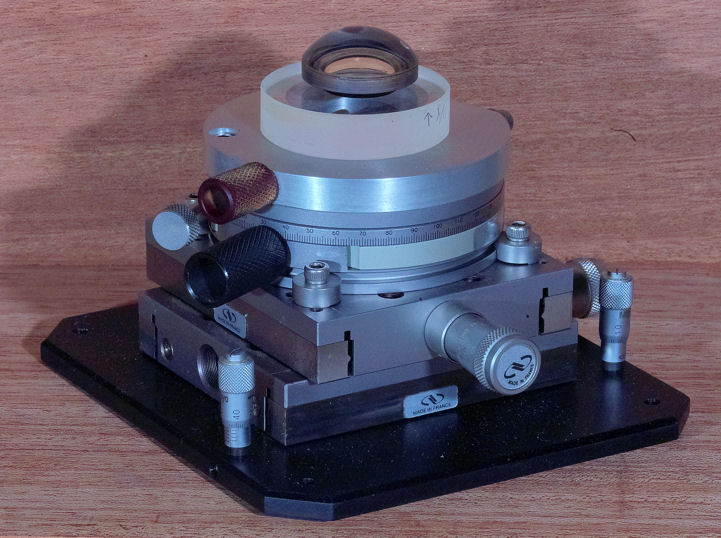

Lens centering and leveling during the re cementing process is critical to the success of the process.. In order to ensure that lenses are aligned to tolerances greatly exceeding original factory tolerances a high precision Mitutoyo measuring microscope and an ultra-precision rotating table on a leveling mount is used to ensure centering to well within 1/100,000 of an inch and an absolutely level surface.. This is a picture of the rotating table with the center triplet from a 50mm f1.5 Sonnar lens placed on top of the optical flat which is used when a lens is re cemented.

This picture shows the rotating stage mounted on the Mitutoyo measuring microscope:

If you have any lens, made for any camera including large format, that needs to be separated and re cemented in order to improve the lens or due to failure, clouding or separation of its original lens cement please send me an email to superwide@earthlink.net by using this link:

This is a picture from 1963 showing an apprentice in the Zeiss factory at Oberkocken polishing a prism. The caption on the back of this picture reads: "Stuttgart - The "Apprentice Workshop" of the Carl Zeiss company, in the industrial area of Stuttgart, is the training ground for the development of world famous lens specialists. In this miniature sized plant, all the techniques of the operating factory are duplicated. Apprentices enter the "Lehrlings Werkstatt" at the age of 14 or 15. The normal training period of 3 years is free of charge as the entire training costs plus spending money are covered by the company, an institution that turns out many of the world's finest lens experts." In the background of the picture you can see an eight station lens polishing machine. On the work bench you can see all of the tools needed to polish a perfect polished prism with perfectly flat sides from a cast optical glass blank prism, two of which are shown on the bench. This bit of apprentice training certainly taught the most extreme patience and persistence.

The Correction of Focusing Stiffness:

There have been a lot of comments about focusing stiffness of the larger diameter lenses over the years, and with regard to the Zeiss Contax 85mm f2.0 Sonnar in particular. Not much could be done about it until now. I have recently compounded and tested special grease, which when used in combination with a Swiss treatment, allows a considerable reduction in focusing stiffness to be obtained. The custom compounded grease is made here using components manufactured by a German lubrication company that supplies Zeiss with optical grease. The problem is this grease is very light and fugitive and tends to move quickly throughout the lens. This spreading is blocked by the use of a special Swiss made watchmaker's compound specially designed to chemically block completely the spreading of oil and grease permanently. This treatment hasn't been available in this country until recently. It's called Mobius Fixodrop and is very expensive, costing about $125.00 per 100 milliliter bottle. But it works like a charm to fence in the very high lubricity grease, keep it in the focusing helicals where it belongs for many years, and allow this special grease to be used in an 85 mm Sonar to lighten up the focusing to the maximum extent possible.

Lens Services Per Listed Lens:

The service consists of:

- Complete disassembly and hand/ultrasonic cleaning of all mechanical components.

- Removal and cleaning of all lens optical elements. Special laboratory grade solvents are used to clean them. These evaporate without leaving a trace.

- Note that fungus removal is automatically included with lens element cleaning. If the problem is determined to be cemented lens element separation or lens separation, repair of this problem is priced in the LENS REPAIR section.

- Black edge painting on individual lens elements is touched up or replaced as required.

- Lubricants in the aperture and iris mechanism are removed completely using ultrasonic cleaning with pure solvents. Replacement lubricant is teflon based synthetic grease which will not deteriorate.

- Aperture/Focus Engraving paint is touched up as required using New Hermes Engravograph filling paint to obtain that original factory sheen. We do not use lacquer sticks.

- Lens aperture calibration is tested on a test camera body using a Precision Camera Tester.

- The lens is mounted on a test camera and the final focus adjustment is taken to perfection using a ZTS Precision Focus Tester and a Bligh Autocollimator.

- Lens servicing results are always best when performed on the camera that the lens will be used on.

This is a picture of a set of aperture blades from a Zeiss-Opton 50mm f1.5 Sonnar lens. They have been ruined by rust and staining of the bluing. This lens was purchased by a customer who could not see this damage because it was obscured by a thick coat of oil on the blades. The oil that comes from deteriorated grease does not protect against rusting and can accelerate it by trapping moisture. This oil can also make it very difficult to see damage.

For years there have been a lot of discussions about the proper way to safety clean a lens. Zeiss has ended all arguments by producing its own brand of packaged pre-wetted lens cleaning cloths. Just follow the directions provided on the side of the box and you cannot go wrong. I highly recommend that you exclusively use genuine Zeiss lens cleaning cloths on your fine pre and post war Zeiss Lenses. If your lens needs cleaning there's no point in risking a scratch by using anything else. Packages of 50 individually sealed pre moistened 6" x 5" cloths (not paper) are available here.

Prices for Rangefinder and Contarex Lenses

The following lenses are accepted for regular overhaul service at the stipulated prices (Price when performed with camera body overhaul). Modern Contax/Yashica Zeiss Lenses and Lenses for other cameras are also overhauled here but are not specifically listed below so please inquire.

Many prices are On Request (OR). Please use this email link to request the current overhaul price and turnaround time:

Rangefinder Camera Lenses

| Service | Cost |

|---|---|

| a. Rigid 50 mm f1.5 Sonnar (Pre-War) | $135.00 ($85.00) |

| a. Contaflex TLR 50mm 1.5 Sonnar | OR |

| a. Coated Rigid 50 mm f1.5 Sonnar (Pre-War) | $135.00 ($85.00) |

| a. Zeiss-Opton 50 mm f1.5 Sonnar | $135.00 ($85.00) |

| a. Carl Zeiss 50mm f1.5 Sonnar (Post-War) | $135.00 ($85.00) |

| a. Leica Screw mount 50 mm f1.5 Sonnar | OR |

| a. Russian Made Copy of 50 mm f1.5 Sonnar | $135.00 ($85.00) |

| a. 50mm f1.4 Nikor | $155.00 (105.00) |

| Service | Cost |

|---|---|

| b. Rigid Uncoated Pre-War Carl Zeiss Jena | $135.00 ($85.00) |

| b. Rigid Coated Pre-War Carl Zeiss Jena | $135.00 ($85.00) |

| b. Rigid Zeiss-Opton T | $135.00 ($85.00) |

| b. Rigid Carl Zeiss (Post War) | $135.00 ($85.00) |

| b. Collapsible Uncoated Pre-War Carl Zeiss Jena | $135.00 ($85.00) |

| b. Collapsible Coated Pre-War Carl Zeiss Jena | $135.00 ($85.00) |

| b. Collapsible Zeiss-Opton T | $135.00 ($85.00) |

| b. Russian Made Copy of 50mm f 2.0 Sonnar | $135.00 ($85.00) |

| Service | Cost |

|---|---|

| c. 50 mm f 3.5 Carl Zeiss Jena (Pre-War) | OR |

| c. 50 mm f 3.5 Carl Zeiss Jena Coated (Pre-War) | OR |

| c. 50mm f 2.9 Carl Zeiss Jena Coated (Pre-War) | OR |

| c. 50 mm f 3.5 Zeiss-Opton (Post-War) | OR |

| c. 50 mm f 3.5 Carl Zeiss (Post-War) | OR |

| Service | Cost |

|---|---|

| d. 50 mm f 2.0 Sonnar | OR |

| d. 50 mm f 1.5 Sonnar | OR |

| d. 85 mm f 2.0 Sonnar | OR |

| d. 135 mm f 4.0 Sonnar | OR |

| d. 35 mm f 3.5 Biogon | OR |

| d. 35 mm f 2.8 Biogon | OR |

| d. Russian Copy of above lenses marked Jupiter or Zeiss | OR |

| Service | Cost |

|---|---|

| e. 85 mm f 2.0 Sonnar Pre-War Carl Zeiss Jena Coated | OR |

| e. 85 mm f 2.0 Sonnar Pre-War Carl Zeiss Jena | OR |

| e. 85 mm f 2.0 Zeiss-Opton Post War | OR |

| e. 85 mm f 2.0 Carl Zeiss Post War | OR |

| e. 85mm f 4.0 Carl Zeiss Post War | OR |

| e. Black Enamel 8.5 cm f4.0 Carl Zeiss Jena Sonnar | OR |

| e. 85mm f 4.0 Carl Zeiss Pre War | OR |

| e. 85 mm f 2.0 Russian Lens | OR |

| e. 105 mm Nikor | OR |

| e. Black Enamel Contax I 13.5 cm f4.0 Carl Zeiss Jena Sonnar | OR |

| e. 135 mm f 4.0 Sonnar Pre-War Carl Zeiss Jena | OR |

| e. 135 mm f 4.0 Zeiss-Opton Post War | OR |

| e. 135 mm f 4.0 Carl Zeiss Post War | OR |

| e. 180 mm f 6.8 Carl Zeiss Jena (Pre-War) | OR |

| e. Black Enamel Contax I 180 mm f 6.8 Carl Zeiss Jena (Pre-War) | OR |

| e. 180 mm f 6.6 Schneider Tele Xenar | OR |

| e. 180 mm f 2.8 Carl Zeiss Jena for Flektoscope | OR |

| e. 300 mm f 2.8 Carl Zeiss Jena for Flektoscope | OR |

| e. 500 mm f 8.0 Carl Zeiss Jena for Flektoscope | OR |

| Service | Cost |

|---|---|

| f. 28 mm f 8.0 Tessar Uncoated Carl Zeiss Jena (Pre-War) | OR |

| f. 35 mm f 3.5 Biogon Uncoated Carl Zeiss Jena (Pre-War) | OR |

| f. 35 mm f 3.5 Biogon T Coated Carl Zeiss Jena (Pre-War) | OR |

| f. 35 mm f 3.5 Biogon Zeiss-Opton (Post-War) | OR |

| f. 35 mm f 3.5 Biogon Carl Zeiss (Post-War) | OR |

| f. 35 mm f 2.8 Biogon Zeiss-Opton (Post-War) | OR |

| f. 35 mm f 2.8 Biogon Carl Zeiss Jena (Pre-War) | OR |

| f. 35 mm f 2.8 Biogon Coated Carl Zeiss Jena (Pre-War) | OR |

| f. 35 mm f 2.5 Nikor | OR |

| f. 35 mm f3.5 Planar | OR |

| f. 35 mm f3.5 Biometar | OR |

| f. 35 mm f2.8 T Biotar | OR |

| f. 35 mm f4.5 Orthometar | OR |

| f. 25 mm Topogon | OR |

| f. 21 mm Biogon | OR |

| f. Russian 35mm Lens | OR |

| Service | Cost |

|---|---|

| g. 135 mm Nikor | OR |

| g. 35 mm Nikor | OR |

Contarex Lenses

| Service | Cost |

|---|---|

| h. 18 mm Distagon | OR |

| h. 21 mm f4.5 Biogon | OR | h. 25 mm Distagon | OR |

| h. 35 mm Distagon | OR |

| h. 50 mm f2.0 Planar | OR |

| h. 50 mm f2.8 Tessar | OR |

| h. 55 mm f1.4 Planar | OR |

| h. 85 mm f2.0 Sonnar | OR |

| h. 135 mm 4.0 Sonnar | OR |

| h. 135 mm f2.8 Sonnar | OR |

| h. 180 mm f2.8 Sonnar | OR |

| h. 250 mm f4.0 Sonnar | OR |

| h. 250 mm f4.0 Sonnar Manual Aperture | OR |

| h. Vario Sonnar Zoom Lenses | $575.00

to $900.00 Depends upon condition. |

Special Lenses:

There are a variety of extremely rare lenses made in Contax mount. Servicing for these special lenses is available. Please inquire if your lens is not listed above by using this email link:

If you have a non-Zeiss lens please inquire.

If ever you've wondered what the lens grinding department at Zeiss looked like back in 1947 here is a picture of the lens grinding machines in action. The technician is applying some abrasive to the iron lens form being used to grind a lens. Note the complex machinery above and below the grinding platform used to rotate the platform and move it from side to side during the grinding process. Today lenses are manufactured using diamond coated lens shaped abrasive forms that form a lens surface very quickly. These old machines are obsolete but many lenses being loved and used today were made on these machines in the Jena factory.

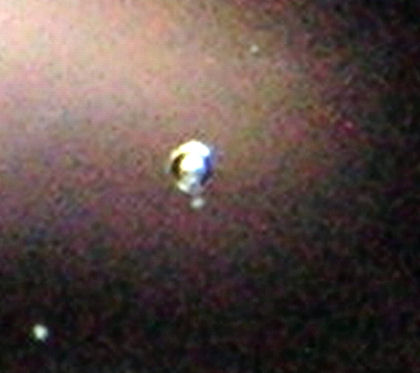

Here is a picture of bubbles contained in the optical glass of a Contax 50mm f2.0 Coated postwar Sonnar:

This bubbles are the result of a secret (toxic metal) ingredient giving off gas when the Zeiss optical glass is taken to a very high temperature during its manufacture. There are three reasons bubbles are not in the glass of lenses made today. The first is modern European safety regulations prohibit the use of toxic metals in optical glass. The second is with the implementation of this insane requirement the temperature of the optical glass need not be taken to such a high temperature during its manufacture. The third is that some manufacturers today use use German names under license on their lenses but also use inferior optical glass in them. It also means the lens without bubbles will not perform as well as a lens with bubbles. What does all this tell you? It tells you that lenses made in Germany by Zeiss prior to the introduction of the Euro as a common currency are to be very highly prized far above anything made today and if you have a lens with bubbles in it this is a cause for rejoicing.

Please use this link to send email to superwide@earthlink.net:

Difficult Lenses:

If you have sent your lens to other shops and have had it returned with the explanation that it is not economical for repair, or if you lens has been badly damaged, or if you have been told it is impossible to repair send it here. There has not yet been one lens that has come here and had not been completely restored.

Notes:

- Servicing depends upon the ability to disassemble the lens without damage. Experience has demonstrated that some lenses may be frozen together and be unserviceable. Unserviceable lenses will be returned without charge other than for shipping and the estimate charge.

- Damage to the filter thread ring or other lens parts may affect the ability to service the lens. If this is a problem, you will be advised of available repairs. If servicing is not possible due to thread damage or other damage, the lens will be returned to you at no charge other than for shipping and the estimation charge.

- Excessive corrosion, mold or damage requiring extensive additional work is at additional cost. This cost will vary depending upon the amount of time and effort and/or parts required.

Lens Repairs

Full machine shop services are available to replace missing or damaged components. Each damaged lens is different. Repaired lenses are precision aligned using an Auto-Collimator to ensure original factory performance. Repair costs are in addition to the stipulated servicing cost provided above.

Prices for typical repairs are as follows:

- Filter Ring Straightening: $45.00 This service includes careful bending of the filter ring using a variety of tools specific to this purpose to obtain the best possible appearance and smoothest possible filter attachment. The exterior of the filter ring is cleaned and repainted.

- Filter Ring Replacement: $95.00 Many lenses have separate filter rings. Replacement rings can be made of brass or aluminum that are indistinguishable from the original. These replacements are painted with hard baked enamel.

- Other parts as necessary. Price depends upon availability and/or the necessity to custom fabricate. Please inquire.

- Lens Element Re cementing: $95.00 and up depending upon the lens. This price is for the separation, cleaning and precision re-cementing of the the lens element. A complete lens overhaul is also necessary as part of the process of re cementing and is not quoted here in this paragraph.

- Zeiss Opton Sonnar 50 mm f1.5 Triplet Holder Repair: $50.00. This model lens utilizes a brass frame/aluminum bezel threaded holder to encase the triplet and hold it in position. In some lenses the threads on the aluminum bezel are improperly cut. The result is that the aluminum bezel cannot be fully threaded onto the frame. This defect was handled at the factory through the application of additional black paint to "glue" the element in place. Over time this paint shrinks, and the element becomes loose, and the element can move out of proper position due to normal bumps from normal usage. Due to the high curvature of the front of the triplet this problem can only be diagnosed by examination with the front element removed.

- Lens Re coating. Lens element re coating services are available. Please inquire.

- External corrosion removal and external re polishing $30.00.

Lens and Camera Fungus

There is a lot of confusion about lens and camera fungus. It's really not all that complicated. The first thing to understand is that fungus cannot grow without food. In cameras food usually consists of old grease, oil from old deteriorated grease, rubber seals, mirror damping and body sealing foam, and oil from photographer's sweat.

There are basically two types of mold and fungus, oxygen loving and non-oxygen loving. Oxygen loving mold typically exudes carbon dioxide as it lives and is relatively harmless to lenses and coatings. But it does exhale water which can cause rust. It generally will not consume plastic, rubber or foam. Mold that thrives in an oxygen deprived environment exudes a very powerful acid. This acid is responsible for coating damage and lens etching. It also dissolves rubber, some plastics and foam. Determining which type of mold inhabits a particular lens or camera is almost impossible for anyone but an expert to do based upon appearance. Mold is like mushrooms and can have a variety of appearances based upon what stage of life it is in. It's usually best to just assume its the worst kind.

Cameras and lenses that are stored in carefully sealed containers can develop both kinds of mold in sequence. First the oxygen loving mold gets to work and uses up the oxygen in the camera or lens and then the low oxygen loving mold will get to work. Even if a camera or lens is sealed tightly in a plastic bag with fresh desiccant mold will grow given the right temperature, atmosphere and food conditions.

To prevent mold the best thing to do is to keep the camera or lens in a proper humidity environment of 40 degrees of relative humidity, temperature at about 72 degrees Fahrenheit, and to exercise it regularly to keep the internal lens or camera atmosphere well oxygenated.

Getting back to the matter of mold food it is important to realize that petroleum based lubricants and mold have grown up together over many millions of years. There is nothing strange about mold eating petroleum based aperture damping or camera lubricating grease. It's a normal thing. The simple fact of the matter is the longer a camera or lens has been in existence the more likely it is that the grease inside it has become inoculated with one or more species of mold who are just waiting for some optimum condition to occur so that they can grow.

The one and only way to ensure that your camera or lens cannot become a victim of mold is to ensure that it is cleaned completely of the old lubricant and then all parts must be thoroughly cleaned to remove all traces of the oil that has leaked from the grease over time. Then it must be properly lubricated with modern synthetic grease that is not petroleum based.

Keep in mind that just because a shop says it is using modern synthetic grease and oils doesn't mean they are. If you are unsure just give your camera or lens the smell test after it has been serviced. If it smells like "machine oil" or has a slightly sulfurous odor then the lubricants are not modern synthetic ones. Modern synthetic oils and greases have very large molecules. These molecules are so large they do not get released into the air and so they have no smell.

Once a lens is infected with mold or fungus there is no easy way out. The only remedy is a thorough and TOTAL cleaning and disinfect ion. In some cases it is even necessary to remove and replace lens edge blacking paint because it also can become infected. This is the only hard and fast rule. There are many kinds of molds and fungi that can infect a lens and once a lens is infected the spores are everywhere inside it and the cleaning must be complete to ensure it does not return.

Lens and Camera Grease

There is a lot of confusion about lens and camera grease and oil. Here's how it is. All petroleum based greases consist of three parts. These are a soap, oil(s), and stabilizers. Typically the soap component is a soap made with lead or lithium metal and which is not water soluble. Soap made for the home is typically made with sodium and is water soluble. When one uses household soap to wash the hands, the soap dissolves in the water and the petroleum component of the soap attaches to the the oil on the skin and carries it away down the drain. In camera grease the soap holds the oil to keep it in one place and to keep it from running away. The stabilizer is used to slow down the attack of oxygen on the soap which tends to break it up and reduce its effectiveness in holding the oil. Over a long time, as the soap breaks down, the oil is released to migrate into the camera or lens. All petroleum based grease deteriorates over time. Based upon the quality and purity of the products this process can be either long or short.

Once a petroleum based grease has completely deteriorated and released all of its oil the remaining soap will tend to harden and become sticky and then will form a hard deposit. Once grease looses its oil it is no longer a lubricant. It is more like an adhesive.

In the 1960's manufacturer's started to use a new type of grease called "molybdenum disulfide" (MD) grease. MD is a powdery solid lubricant like graphite but better. MD grease is basically all the same. Today you usually come across it when it used in the wheel bearings of automobiles. The problem with MD grease is that there is no soap in it to contain its oil. The result is the oil gets released from the grease quickly and the sold MD remains making the camera or lens sluggish or sticky. The use of MD grease in the Zeiss Ikon Contarex is a big reason why this camera put Zeiss out of the camera making business.

It is possible today to substitute modern synthetic greases for the old ones in many applications. It is also possible to have these hand made to be analogues of the older greases that used MD. Some applications require the older grease. These are typically lenses with aluminum helicals using sliding pads or lenses made right after the war that use primitive aluminum alloys. These lenses require a grease that has the property of preventing self welding. Greases that prevent self welding typically are proprietary and are available only in Germany, and are petroleum based.

Why Aperture Blade Oil is So Bad

When there is visible oil on the aperture blades there is oil on the lens element surfaces inside the lens assembly. Lenses work on a basic principle of physics that says the degree to which a ray of light is bent is proportional to the hardness difference between the surfaces through which the light travels. When a manufacturer assembles a lens at the factory great care is taken to ensure the lens elements are clean and free of any trace of oil. When a lens becomes coated with oil the oil acts as a secondary surface which bends the light itself. The oil films on the various elements in effect becomes a number of thin lenses that have become introduced into the lens design and the results are never good.

If you have an old camera or lens and there is oil on the aperture blades there is absolutely no point in judging the performance of the lens. It is only when the lens has been properly cleaned that the true performance of the lens will be revealed. Old lenses with oil films on them will generally produce disappointing results when the results are compared to lenses which are freshly manufactured, even fresh ones that are intrinsically vastly inferior.

When one looks inside an old lens what is actually seen is an optical illusion. This optical illusion is caused by all of the possible partial reflections of all of the inner surfaces of all of the lens elements. Shining a flashlight through an old lens with oil films on the elements is effectively turning the lens into a special form of kaleidoscope. It's no way to judge the potential "Bokeh" of and sharpness that the lens can produce when it is brought back to the originally manufactured state of cleanliness.

Keep in mind that a lens in which the original damping grease has released all of its oil can show no oil on the aperture blades. In lenses that are very old, or which have been kept in hot environments, it is possible that all the oil released from all of the grease has migrated away from the blades and into inner recesses of the lens. The best rule of thumb is that if a lens is 20 to 25 years old or more, and it has not been thoroughly cleaned, its best to assume the inner lens elements have an oil film on them.

It's not simple to clean a lens coated with oil released from deteriorated aperture grease. Typically a number of cleanings using different solvents are required to get it all out of the lens and off the lens surfaces. The reason for this is that grease manufacturers would typically use a mixture of specially prepared oils whose properties would help each other stay with the grease base soap longer. These oils are typically soluble in solvents which are chemically different from each other in a fundamental ways and the chemical terms for these differences are "polarity" and "chirality". To get every trace of all of the oils out of the lens it is necessary to use solvents whose basic chemical properties match those of the oils.

The Dangers of Buying an Oiled Lens

An oiled lens is one that has been treated with oil to "correct" separation of the elements. There are basically three types of lens cement: Balsam, Epoxy and UV Curing Adhesive. All lenses up to sometime in the mid 1960's used Balsam. Balsam is a sticky highly refined tree resin that never actually hardens. It's easy to use and highly effective but sensitive to heat and discoloring due to oxidation over time. We all know about Epoxy. It's a modern chemical two part chemical adhesive. It just gets harder and harder over the years and never stops curing and getting harder. As it hardens it can become hard enough so that it looses its adhesive attachment to the lenses. This causes the separation evident in a number of Zeiss lenses made in the 1960's to the 1980's. UV curing adhesive is what is used today. It can be removed, it remains pliable and sticky like Balsam, and its generally a good thing.

The problem with epoxy is that when its fully cured all the atoms inside it are attached to each other. This makes it one big molecule and so solvents will not work on it. Heat works, but the temperature must be so high as to cause the coatings to evaporate. When the lens is separated with heat it must be recoated afterward.

Some enterprising people have found a shortcut by using oil. When a lens is separated partially the distance between the two separated lens elements is extraordinarily small, about the same as a wavelength of light. If very fine oil is applied to the edge of the separation capillary action will pull the oil into the lens. The oil will fill the void and the lens will appear to be cured. But once the oil in inside this space it is there forever. The main problem with this is that the oil lubricates the edge of the separation and acts to increase it over time. The effect is temporary and it will list shorter or longer depending upon many factors such as temperature cycling, mechanical shocks and the oil that is used.

I have purchased lenses which have later turned out to be oiled. In time the oil will largely find its way out of the lens. It may take years but this will happen. I know this because lenses I have purchased, which were oiled, in time had their original separation restored while they were on the shelf. I have also seen oiled lenses sent here for repair. When the lens elements were properly cleaned the oil came out of the separation and the lens was a wreck.

When you buy a lens always buy it with a guarantee that it has not been oiled. Get at least a three year return guarantee. If you want to read the ramblings of a group of people who actually do this kind of thing and then sell their lenses use the link provided below.

Link List:

- If your Contax, Contarex, or other Zeiss lens has a problem and you want it to be corrected please email me

- If you want to read about people who oil lenses and sell them use this link: Separation

- This site is the history of lens cementing : Lens Cementing

- If you want to know about the One Year Lens Repair or Overhaul Guarantee use this link: Guarantee.