Zeiss Ikon Contax Camera Repair

A home for your Zeiss Ikon Contax, Contarex or Super Ikonta camera!

Information

- Services

- Scheduling Services

- Waiting List Info

- Guarantee

- What is a CLA?

- What a CLA leaves out

- Purchasing a Contax Camera?

- Camera Equipment Sales

Cameras Serviced & Pricing

- Contaflex TLR

- Contarex Bullseye

- Contax I

- Contax II and III

- Contax IIa and IIIa

- Zeiss Lenses

- Kiev Cameras

- Contaflex SLR

- Kyocera Contax

Overhauls

What a CLA Leaves Out

I have been asked numerous times recently what is the main difference between a complete overhaul and a CLA and why an overhaul costs more and is more time consuming than a CLA.

The following picture sums it all up. It shows the right shutter tape attachment point on a shutter where this has failed and ripped off due to overstress that results from an over tightened shutter curtain spring. You can clearly see that the metal is aluminum and it is very very thin. When a shutter spring is over tightened it causes this connection point to flex and finally fail. Aluminum, when it is overstressed, will fail after a certain number of cycles and has a vastly shortened service life. An over tightened Contax IIa/IIIa shutter spring will definitely result in this kind of damage in time. It all depends on how long it takes to process the camera through the necessary number of exposures.

It is a normal practice during a normal CLA to simply over tighten the shutter curtain springs to "cure" the high speed blanking which is the symptom of a dry and dirty shutter. When a camera is completely and properly overhauled the whole final adjustment process is intended to result in the lowest possible shutter spring tension consistent with the most accurate high shutter speeds. But this process is time consuming.

This is due to the number of shutter speed adjustment points. There are seven adjustment points and they all effect each other. Each camera is hand made out of hand made parts and each camera is significantly different from each other that each requires the whole complex treatment. Consider that with eight adjustment points there are 1024 possible adjustment combinations of all the points. It just takes time and patience to find the best combination for each camera with the condition the shutter spring tension must be the lowest possible.

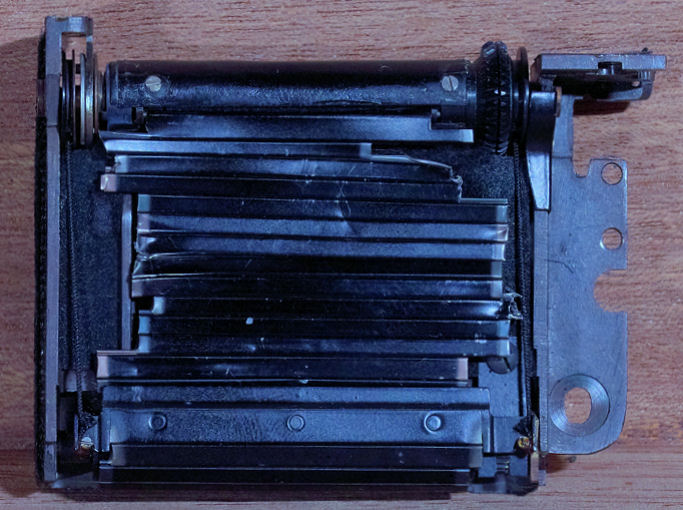

I recently purchased the final inventory of Contax parts and tools from the owner of the now closed Zeiss Ikon Canada Camera Repair Facility. In this astounding collection was a Contax IIa/IIIa shutter that perfectly demonstrates the effects of shutter springs adjusted too tight. The first picture is of the shutter showing the damage to the shutter curtains and curtain slats that can occur merely due to springs being too tight. This picture shows how thin aluminum just falls apart when it is worn out.

This picture shows the shutter open and is close ups of the right and left shutter curtain tapes:

The severe fraying is evident.

The total overhaul process takes about 10 to 14 days to accomplish properly. The process is of incrementally and slowly increasing shutter spring tension one click per day until the speeds of a fully cleaned and properly lubricated and adjusted camera are stable and accurate. And if, when this is done, the springs are too tight, the camera adjustment process must be done over, chaging the other adjustment points, until the camera is accurate, stable and the shutter springs are at th minimum tension because the lifetime of the camera is at stake. There are eight separate shutter adjustments that affect shutter performance and adjusting the spring tension is the last one in the process.

A very serious problem with old Contaxes that have been superficially worked on is mold. Here is a picture of mold colonies inside the body shell of a Contax IIa camera:

This mold, can in some sensitive individuals, provoke an extremely serious allergic reaction that can include the sudden onset of severe asthma, hives, and other serious allergic symptoms. This reaction can happen in people who have never had a single such attack before or who never knew they were allergic to anything. This kind of mold is called white rot and it feeds on petroleum products. it is a sensitizer which means that repeated exposure to it, over time, will cause an allergy to it to develop which will not be noticed until the symptoms become very severe. These mold colonies are throughout the entire camera and this why a properly overhauled camera is completely and thoroughly cleaned. This cleaning process is time consuming and adds to the cost of a thorough and genuine overhaul.

I have had a number of customers submit their cameras to me for evaluation after having them "renewed", "overhauled", "CLA' d", "re breathed", "resurrected" or what passes by any other name to be the same thing provided by a great many operators charging for these services. In all of these cameras I have seen nothing but over tightened shutter curtain springs. In some I have also seen grease superficially painted uselessly on the tops of gears where it can have no other effect than to deflect criticism and counter a well deserved charge of fraud if the camera should be competently examined after the service.

Here's another picture of the same Contax IIa/IIIa shutter. Down at the very far right you can see the exposed top of a brass gear. This is actually a latch for the shutter curtain tightening screw. This screw is accessible from outside the camera through a hole in the body and so it is possible to "cure" high speed blanking by adjusting this screw without disassembling the camera. But, the latch can only be released when the curtain assembly is removed from the camera body. it is only possible to relax the springs after the camera has been disassembled and so the normal practice is to excessively over tighten the springs.

It is entirely possible that if you bought a camera overhaul on Ebay or elsewhere what you actually got was a screwdriver tightening this screw until the shutter stopped blanking and then the camera was wiped clean and was returned to you. You'll only know for yourself and be absolutely certain this was done when the shutter tape attachment point breaks. Then the repair will be very expensive because the only source of replacement parts is a parts camera and each body contains only one of the necessary part.

Here is an easy way to check for over tightened shutter springs. Check the 1/1250 speed of your IIa or IIIa on a shutter speed tester. The 1/1250 speed is the "run free" speed of the camera and if it is between 1/850 and 1/1500 chances are the spring tension is ok. One of the contradictory things about the Contax shutter is that tightening the shutter springs does not make the shutter faster; it makes it slower at high speeds of 1/250, 1/500 and 1/1250. The cameras which were recently CLA' d, and which I have examined, typically had actual shutter performance between 1/150 and 1/350 when set at 1/1250 and this performance is proof positive of shutter springs dangerously over tightened.

My expectation is that within the next five years I'm going to see an outright epidemic of this kind of shutter damage because so many camera repair operators offering a quick and cheap service have merely cranked up the shutter spring tension good and tight rather than respecting the camera and its owner.

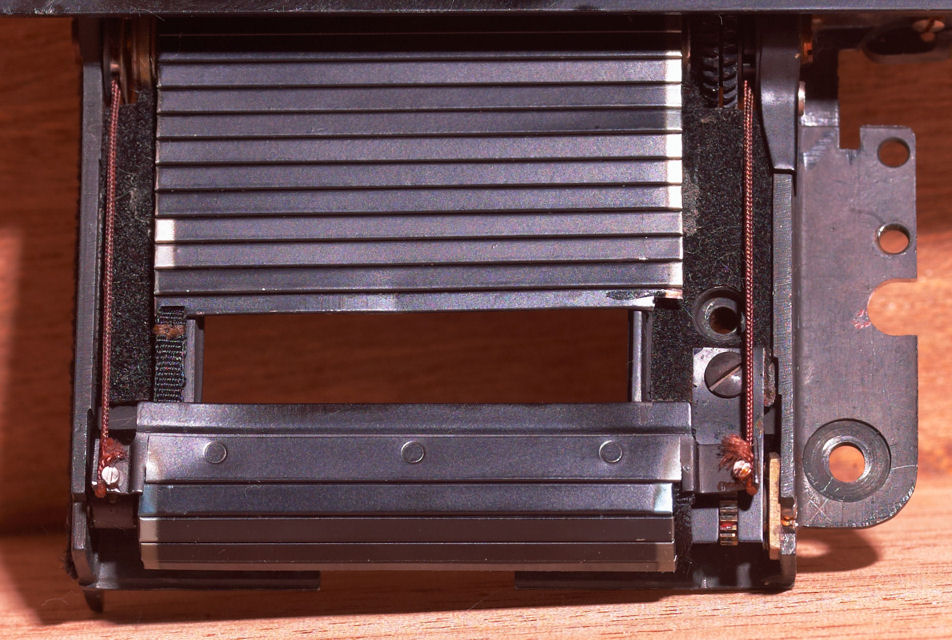

Another very important consideration not included in a regular CLA is proper lubrication of the shutter curtain slats themselves. The fact is these tiny high precision slats are made of metal, are attached by a flexible joint where there is metal-to-metal moving contact, and Zeiss specified the slats should be lubricated. In order to lubricate these slats it is important to select the proper lubricant. The slats are made of aluminum and use of the improper lubricant will actually promote accelerated wear. It is better to leave the slats dry than to use a lubricant that is not specifically designed for use with aluminum and to stay where it is put for a very long time. Here's an edge on picture of the Contax IIa/IIIa shutter curtain slats. This picture shows these tiny slats are joined by a very clever, but intrinsically high friction and potentially fast wearing, locking scroll type joint:

Another consideration is that if the shutter spring tension is too great, the wear of the slat joints will be greatly increased. It has been necessary to replace entire shutters due to premature wear out resulting from excessive shutter spring tension.

Very few people have any kind of knowledge of the inner workings of their precious Contax camera and this is normal because Contax repair and servicing is a very specialized line of work requiring specialized knowledge, skills and tools. Camera owners depend upon the good faith and honesty of the people to whom they entrust their Contax camera for regular or restoration servicing and repairs. The general camera servicing which is described by the term “Clean, Lubricate and Adjust” or CLA contains no statement of exception. Without a specific statement of exception the normal understanding of the general camera owner has to be that a normal CLA service will result in their camera being completely cleaned, lubricated and adjusted with no important part of the camera being excluded or left out. Unfortunately, this is not true. In a normal CLA important parts of the camera mechanism are not serviced. They are not cleaned, lubricated or adjusted. This means that if they are dirty and dry when the camera was presented for a CLA they will be dirty and dry when the camera is returned to the customer and his money is collected. He will not know that parts that are critical to the service life of the camera have been excluded from the CLA service. This is a very serious matter because it seems to me to be a fundamental violation of trust. Anyone who is competent enough to be paid to perform CLA services has to have enough knowledge of the Contax camera to know that to leave these parts out of the service is a serious omission. It is clear to me to understand from talking to many camera owners that when a person has his camera “CLA’d” it is his assumption the camera has been completely serviced. This omission is the reason I use the term overhaul to describe the camera service provided here and do not use the term CLA.

I want to make the point here that I have disassembled and examined cameras that have been described to have been "overhauled" for $124.95 plus "free" shipping. The receipt provided to the camera owners had the word "overhaul" on it many times. But the camera was dirty inside with dirty parts and the only overhaul that had been done was to paint automotive bearing grease uselessly on screw tops and gear tops. The shutter springs on these cameras had been set very dangerously tight. Watch out for words.

The main difference between a complete overhaul and a CLA is the winding mechanism. Every CLA I have seen advertised and described and every camera sent here for an overhaul following a CLA has left out the winding mechanism. There are a number of reasons why the winding mechanism is left out of a CLA and the top two are time and degree of difficulty. Both the degree of difficulty and the amount of time it takes to disassemble and reassemble a Contax camera increase tremendously when a camera has to be disassembled to the extent that the main parts in the winding mechanism can be removed from the camera. They are buried deep inside the camera and to get them out requires the camera be disassembled completely whereas with a quick CLA the camera can be disassembled only 35%. When a camera is 100% disassembled all of the main shutter and rangefinder adjustments in the camera are undone. This makes it necessary to completely re calibrate everything when the camera is reassembled. If the winding mechanism is not serviced, the majority of camera adjustments can be left in their original state. This makes things very easy and quick. Recalibrating a camera easily adds a week to the procedure. It is also a very complex procedure requiring a very fine and very experienced touch. The reason for this is that new adjustments tend to drift and they tend also to affect each other. Recalibrating a completely disassembled camera requires time so that the adjustments can be tested for drift and given slight adjustments as the parts settle in. Complete camera disassembly requires the handling of many more parts which requires more skill and time.

When a camera is serviced or CLA’d and the winding mechanism is not included the parts of the camera which are most critical to general long term reliability, proper shutter operation at high speeds and which are most prone to accelerated wear are left unlubricated. This is the case because the original lubricant Zeiss used when the camera was manufactured tends to harden in about 10 years. With most Contax IIa cameras being over 40 years old it is certain that the winding mechanism lubricant hardened and became useless many years ago. In having overhauled hundreds of Contax IIa cameras I have not seen one with a winding mechanism that was not completely dry.

It is very important to understand that old dirty metal will not accept new oil. This is well known among watchmakers. We have been using ultrasonic cleaning on watch parts for over 50 years. The need for metal to be “clean to the bone” is particularly true of the very specialized watch oils. The only way to prepare old metal so that it will bind with the extremely highly refined and sophisticated oil or grease needed to lubricate it properly to prevent friction and wear is to ultrasonically clean it until all of the old lubricant, dirt and surface oxidation is completely removed so that a fresh chemically clean surface is exposed. The following pictures are of parts that have been ultrasonically cleaned for over two hours. This is how long it takes to get parts back to the way they were when they were at the factory.

Let me just take a moment to tell you something about watch oils. The Chinese have recently moved into the watch and clock oil market and are flooding the market with cheap oil labeled to be watch oil. It is pure junk. There is just no possible way that the Chinese watch oil companies have been able in a year or two to be able to even come close to copying the unimaginably sophisticated and time perfected products which are the result of the experience and resources of the Swiss and French watch and clock oil manufacturers who have been in business for hundreds of years. I will NEVER use anything other than the most high premium specialized Swiss and French watch oils on the cameras overhauled here. These are the only lubricants which actually permanently bond to the metal and stay there year after year. Here’s a tip: If you can smell the oil that has been used in your camera it was bought in a hardware store. The most highly refined and sophisticated watch oils have no odor.

There are three main parts of concern in the Contax IIa winding mechanism. They are the most important parts in the camera because they are where the most force and friction are applied and if they become excessively worn the frame spacing and the shutter speeds above 1/100 are permanently ruined. These are shown in the following picture:

The winding knob connects to the top of the winding shaft and when the winding knob is turned the two gears at the bottom of the shaft are rotated, the film is advanced to the next frame and the shutter is cocked. This is where most of the force and work of the camera gets concentrated. Proper lubrication is vital. Active fresh lubricant completely prevents uncorrectable wear to these parts that will result in permanent damage causing unsatisfactory overall camera performance.

This picture shows the winding shaft with the back rotation stop spring installed on it. The spring prevents the winding knob from being rotated backward. It fits very tightly on the shaft. If the shaft is rotated backward the spring tightens and clenches around the shaft preventing rotation.

This picture shows how the winding shaft with the back rotation stop spring fits into the winding shaft post. The post is shown upside down relative to its normal position when installed in the camera. You can see how the back rotation stop spring fits into a slot in the body of the winding shaft post to hold it in place. You can also see the bearing portion of the winding shaft just above the spring. This bearing portion is held in alignment by the bottom portion of the winding shaft post body. These are high precision fitting parts with very close tolerances. When these parts rub against each other dry the result is highly accelerated wear to the bottom bearing portion of the brass shaft post body.

This picture shows a close up of the winding shaft. In the section of the top part of the shaft where the back rotation stop spring fits you can plainly see the wear and grooving cut into the shaft by the unlubricated back rotation stop spring. The grooving and wear on this shaft can easily be felt with a finger. It is very deep. This shaft is in relatively good condition. This camera had not been used much. I often see shafts in much worse condition. Without lubrication this kind of wear happens very quickly and can result in a wind knob with a very wobbly, loose or springy feel that cannot be corrected. In the bottom of the shaft you can see two gears. The top gear is connected to the lower shutter curtain. When the wind shaft is turned by the wind knob this gear winds up the shutter curtains. When the shutter release button is pushed this gear will be released and it will freely rotate. This free rotation is one of the keys to obtaining accurate and reliable speeds of 1/250, 1/500 and 1/1250. If this gear cannot freely rotate or if it is not properly connected to the other shutter gearing the lower curtain will not open quickly enough and the high speed accuracy will be ruined. The lower gear is connected to the film advance gearing in the camera body and imprecise connection to the other film advance gearing causes bad frame spacing.

It is fairly obvious that the lubricant used on this shaft to coat the shaft and the back rotation stop spring is critical. It has to eliminate the very high friction of the spring against the shaft during normal forward rotation. It must stay where it is and not leak into the shutter gear, and not harden or liquefy with age. Zeiss used a number of greases during the manufacture of the Contax IIa in an attempt to find the right one. None of these were satisfactory because lubrication science and engineering were not developed enough at that time, and a suitable grease was not available. It’s not available on the market today. I have had to formulate a custom grease myself to be able to use a grease that satisfies all of the requirements. The grease used must not move down to the shutter speed gear. The shutter speed gear uses a different type of lubricant and the type of grease used on the shaft top will interfere with proper shutter speeds.

This picture is a close up of the winding shaft post. You can see that it is made of brass. The winding shaft is made of steel. Lack of lubrication on these parts results in steel rotating against brass in a condition of high force with accelerated wear being the result. This wear can be compounded if the original grease has become invaded by mold and has become acidic. The winding shaft is held in very precise alignment in the camera by the bearing sections at the top and bottom of the winding shaft post body. You can see these bearing points in this picture:

If the winding shaft post and the winding shaft are not properly lubricated operation of the camera will cause accelerated wear of the bearing and alignment sections of the winding shaft post body. Wear at these points will allow the winding shaft to become cocked in its mount and the shutter gear to not be properly aligned with the other shutter gearing. This will have the result of the top shutter speeds being permanently ruined. Misalignment of the shutter gears introduces friction that interferes with the free rotation of the wind shaft shutter gear. Wear at these points also results in uncorrectable winding knob wobble and general looseness. The misalignment of the film advance gear will cause un smooth operation and uneven frame spacing.

I firmly believe there’s no point in servicing a camera so that when the work is done the most critical parts of the camera have had nothing done to them and they just grind themselves to pieces. I don’t think it’s fair to service a camera and accept payment for this without the owner knowing all of the consequences of what was done or not done to the camera. I don’t think it’s honest to maintain the expectation in the mind of the camera owner that a partial camera cleaning, lubrication and adjustment is being performed instead of a complete one. I believe it is a very bad outcome for rare and valuable Contax cameras to be set up to be used so that in a short time they will be rendered useless and un repairable.

Finally, there is money and logic. A normal CLA is cheap and fast and this always makes people happy. But this fast cheapness comes out of deliberate simplification. It is perpetrated under the cover of the reliable expectation, on the part of the services, in the lack of knowledge about the inner working by the camera by the camera owner. It is only with this lack of information that incomplete CLA’s can be performed at all. It is doubtful that the speed and cheapness will be thought to be a good thing by anyone who knows that the speed and cheapness of the servicing comes as a direct result of the most important work that should have been done on the camera does not being done. As to the argument about the goodness of a low price and quickness of execution of a CLA are a form of economy the math just does not add up to this conclusion. There can be no real economy in paying ½ the price of a real total complete overhaul for a job that is the result of 1/15 the work and 1/10 the skill and which leaves the camera in a condition where with moderate use it will be rendered into an unusable piece of junk that cannot be restored.

All of the Contax cameras ever made are a precious finite historical resource which must be preserved. Up until very recent times there were a large number of camera manufacturers who regularly manufactured new cameras which were injected into the general population of cameras. These cameras provided ample fodder for the camera repair outfits who made a profit by doing incomplete work and by and large they did no harm in hastening the demise of cheaply made cameras. Now, most of these are gone and only those cameras which were made up until now are likely to be here over the long term to come. Because of this the super premium cameras of the past, such as the Contax IIa, must be carefully preserved and not just treated as a throw away economic resource by which the general population of camera owners can be cheated and mulcted of for a relatively small profit. These Contax cameras are unique in every respect because they are the highest possible expression of pure photographic art. They are art just as the work of a great photographer is art. I believe it is a crime to treat them as some kind of slash and burn economic resource to be used up and mined for a relatively insignificant financial return by those who set these precious cameras up to be permanently rendered useless through incomplete work.

Typical CLA Pictures

A Contax IIIa owner recently had his camera given a “servicing”, “overhaul”, “CLA” or whatever you want to call it. The total cost was $124.95 which included “free” shipping. Included with the camera was a receipt for the work and on it the word “overhaul” was used no less than seven times to describe what was done to the camera. He became concerned that the work might not have resulted in a reliable camera and I offered to examine it at no cost and to correct any dangerous conditions that would be found.

The initial examination showed that the three high shutter speeds of 1/250, 1/500 and 1/1250 were actually 1/150, 1/200 and 1/300. This is a sure sign that shutter shading has been corrected by over tightening of the shutter springs. Over tightening of the shutter springs is a dangerous condition because it leads to highly accelerated shutter component wear along with fraying of shutter tapes. When the camera was opened I found the shutter springs had been highly over tightened. After the camera had been given the full Zeisscamera Restoration Treatment the shutters springs were at a normal tension and the shutter performed with all speeds being within 1/10 f stop of their settings.

While it was here, this camera was completely disassembled, examined and given the full Zeisscamera Restoration Treatment. Pictures were taken of the before and after condition of various components. As these pictures are prepared they will be posted in this section of this page so that you can see for yourself what you get for $124.95.

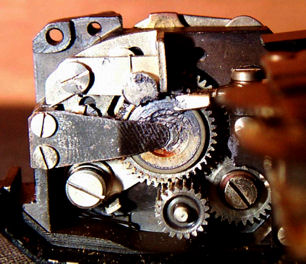

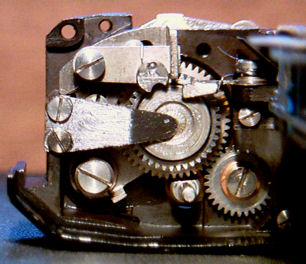

These are before and after pictures of the underside of the winding post. On the top is the camera as it was received here and on the bottom is after the Zeisscamera Treatment. There are three important things shown in these pictures. The first is the use of automotive bearing grease which is the black deposit. The second is the original 50 year old lubricant over which the bearing grease has been applied, and the third is that the old oxidized patina on the copper parts show there has been no ultrasonic cleaning.

You can see that the automotive bearing grease is not effective because it only partially coats the surface of the bottom of the post. If it was effective it would have been spread around as the post was rotated while the camera was wound. The camera was also completely dry of oil everywhere. I found no mechanism with any oil on it anywhere. The only lubricant used was the automotive bearing grease you can see in the picture. On the right you can see the parts have all been cleaned properly and lubricated with both Swiss made watch oil and modern synthetic Teflon grease.

Camera Report

If you want to know just how bad a camera servicing performed by others can be please read the camera report I had to send to a customer who sent his Contax IIIa to me after he had paid over $200.00 for a CLA done by a well known shop.