Zeiss Ikon Contax Camera Repair

A home for your Zeiss Ikon Contax, Contarex or Super Ikonta camera!

Sections

Information

- Services

- Scheduling Services

- Waiting List Info

- Guarantee

- What is a CLA?

- What a CLA leaves out

- Purchasing a Contax Camera?

- Camera Equipment Sales

Cameras Serviced & Pricing

- Contaflex TLR

- Contarex Bullseye

- Contax I

- Contax II and III

- Contax IIa and IIIa

- Zeiss Lenses

- Kiev Cameras

- Contaflex SLR

- Kyocera Contax

Overhauls

The Carl Zeiss 21mm Biogon

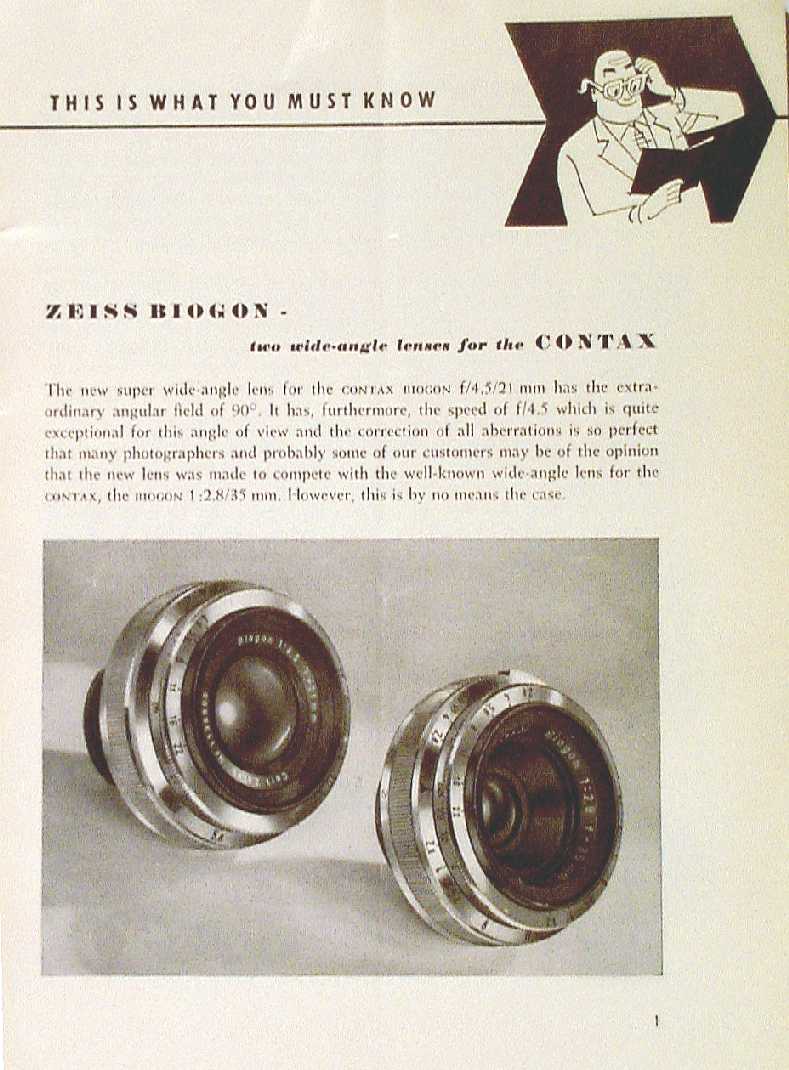

One of the big reasons the line of German made Contax Rangefinder cameras is still so popular is the Super Wide Angle Super Corrected Biogon 21 mm lens. This lens is a true wide angle design unlike the reverse telephoto design Distagons used on the more "modern" single lens reflex cameras. It won't fit on any other camera than the Contax or recently manufactured cameras with a Contax lens mount. The big benefit of the true wide angle design is the ability to completely correct the lens for all aberrations and to minimize barrel distortion. The angular field of view of this super wide and super corrected lens is a whopping 90 degrees.

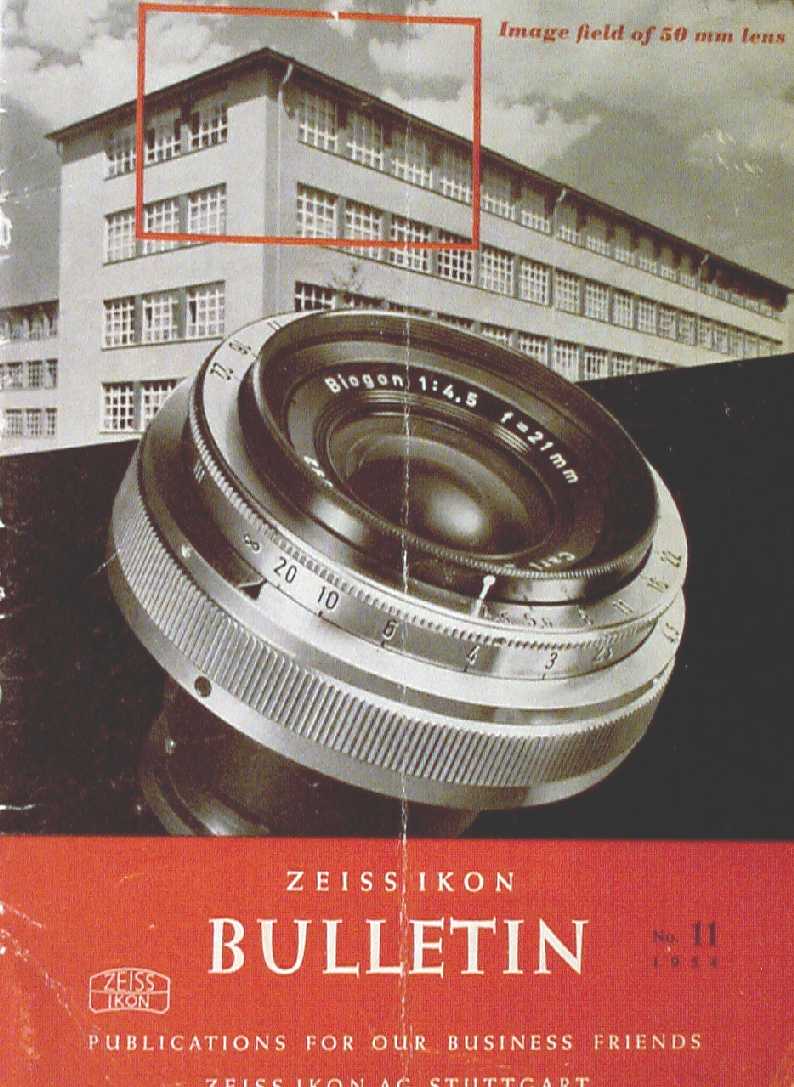

The Biogon 21 mm lens was first announced by Zeiss in its Dealer Bulletin No. 11 of 1954:

Here's what the lens looks like off of the camera. All of its metal parts are hand machined out of solid marine brass.

The 21 Biogon is distinguished from all other Contax lenses by the presence of a rotating flare shield that is attached to the bottom of the lens:

This lens typifies the Zeiss attitude of manufacturing perfection. The next photograph is an oblique view of the barrel. On the side of the inner barrel you can clearly see the great color difference between the area in which the lens elements fit and the remainder of the barrel. This color difference is gold plating. The area where the lens elements fit has been gold plated to avoid long term corrosion welding of the elements into the barrel. The gold also lubricates the elements when they slide into place and this allows the clearances to be very tight ensuring maximum possible centering accuracy.

The next photograph is a detailed picture of the special tool I made to properly extract the front lens elements out of the 21 mm Biogon lens barrel. It has been heavily gold plated to ensure that there is no possibility of damage to the gold plating on the interior of the lens barrel when the lens elements are removed.

The whole idea behind this special tool, and all the other special tools I make to service the Contax and its lenses and accessories is absolute respect for your precious Zeiss equipment. My attitude simply is to do whatever it takes to do the job completely, without compromise, and correctly. I make special tools and never use jury rigged methods to disassemble or assemble your irreplaceable Zeiss photographic equipment.

Here's a picture of this special tool being used to extract the innermost front lens element:

Here's the tool with two elements attached to it:

And here is a picture of the tool used to extract the rear elements with the innermost rear element attached to it:

This is a picture of the rear lens element from the side. Here you can see that Zeiss also gold plated the precision raised edge that maintains centering when the element is installed in the lens barrel:

And finally here's a nice deep look into the freshly cleaned and assembled lens assembly. There is no oil haze now. Everything is perfectly clear.

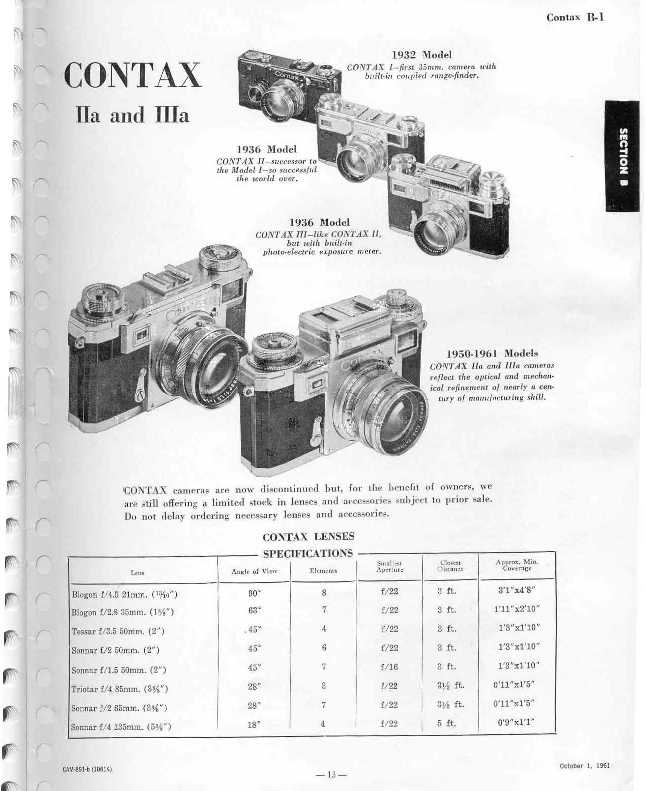

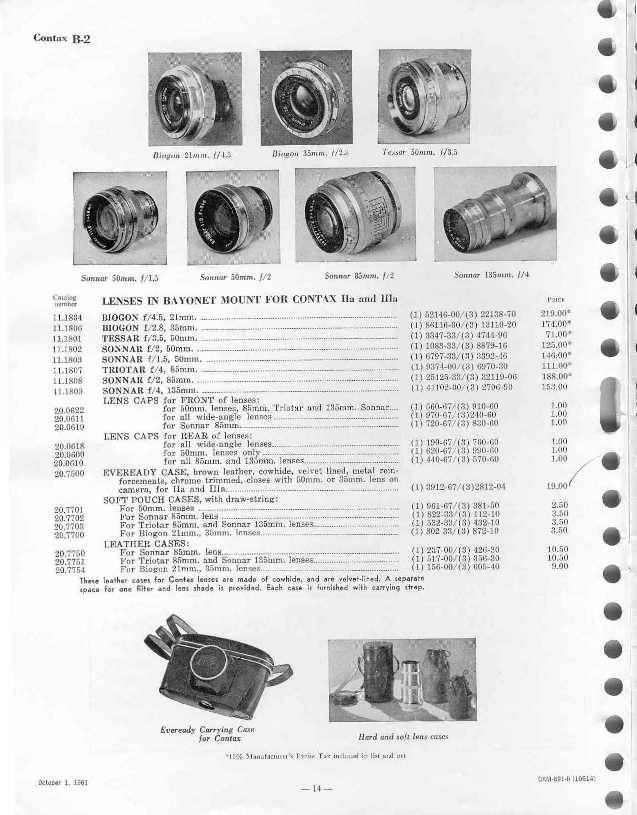

Finally the lens was announced to have been discontinued in the Zeiss dealer catalog of October 1, 1961. The lens was manufactured for only eight years. It's price in the last catalog was $219.00. which is equivalent to $2812.00 today.

The following two catalog pages are linked to much larger and more detailed files of the same pages. If you want to review the more detailed pages at full size just click on the page.

There's one thing you need to know if you intend to obtain a 21mm f4.5 Biogon for yourself. I have recently seen three of these lenses which have spanned the entire production time of this lens. All three of these lenses have had the identical problem, and so I'm sure this is a generic problem. All three lenses had their focus set incorrectly. Their results were unsharp.

It is very difficult to set the focus on this lens. The small size of objects that are even very close combined with the extrordinary depth of field complicate this process. Since all three lenses were set identically my conjecture is that the original assemblers used the appearance of the assembly to judge when the lens was properly set and did not sight through it.